Nozzle performance

A great spray nozzle performance is dependent on a a number of factors such as the manufacturing process, the spraying distribution and the spray impact.

What is the real advantage of getting a cheaper nozzle if the quality is not as promised?

Nowadays as a consumer, we are constantly looking for faster delivery, cheaper price, quick response time, in order to be able to fit in a tight budget-and schedule. Living in a digital world, it is also quite easy to have access to goods online and coming from all over the world. But getting a cheaper produced nozzle has consequences for the nozzle performance and for your business.

Here are 3 tricks to recognize a good nozzle:

- The manufacturing process of the nozzle

- Its spray impact

- Its spraying distribution

1: Manufacturing process

To produce a nozzle, there are 2 main methods (most commons):

- Machining the core material to shape it into the wanted design

- Molding the core material by injecting it in a designed mold

When producing a spray nozzle through injection mold, there is less margin for production errors as the initial mold determine the final shape of the nozzle. However, as soon as the nozzle need precise tooling to shape the orifice, this is where the difference between cheap and high-quality nozzle is visible.

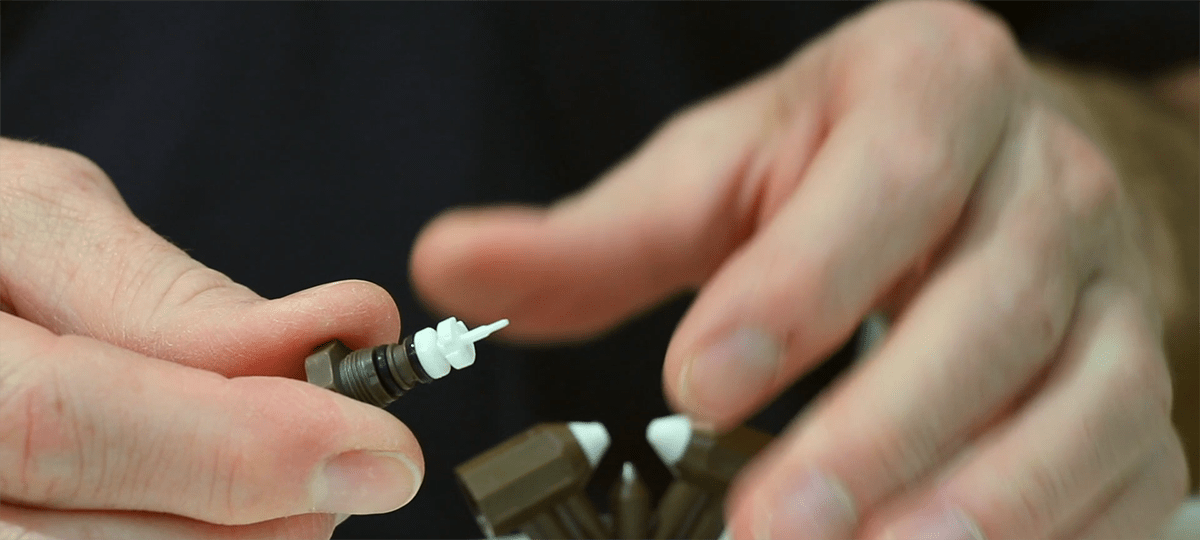

One of the visible points to recognize a cheap produced nozzle is the imprecise tooling during the manufacturing process which will result in:

- Burrs (or “teeth”) at the orifice easily noticeable, but also inside the nozzle’s structure (less visible);

- Visible streaks in the sprayed water pattern.

Burrs:

When spraying a nozzle with burrs, you will see streak of waters clearly visible in the water flow. This is an indication of low-quality manufacturing product made with imprecise tooling.

Streaking:

A spray flow with streaking will have an uneven water density and impact resulting in a larger amount of water consumption, insufficient performance and increase in running cost.

2. Spraying distribution

As a direct consequence of a cheap production quality is a poor performance. You will not reach the result expected with a disparate spray capacity (streaking) and an irregular spray angle (insufficient coverage).

When using nozzles with low and inconsistent quality, it is also difficult for you to design an effective layout and to reach the quality of your end product as expected.

What is the consequence for you if you choose to purchase a lower unit price nozzle with unsteady performance? You will increase your cost and face a decrease in your productivity and efficiency.

This video shows the equal spraying distribution of Ikeuchi's nozzles

3: Spray impact

After checking the spray nozzle’s shape (manufacturing process) and its spraying performance, the most important aspect of the nozzle is the desired impact for the application you are looking for.

Let’s take a trimming nozzle example: It needs a straight solid jet to cut perfectly.

- So, what happen if the impact is weaker? Maybe increasing the water pressure would help. But that means increasing your running cost again.

- What happen if the nozzle drips? This consequence can simply damage the end product if the water drops disturb the production line’s quality.

Therefore, it is important to have a stronger impact with less water used for saving cost and increase productivity.

Nozzle with water drops, disturbing the spray impact of the solid stream jet

So how important is the difference in manufacturing processes with copy products?

To answer to this question, it comes down to the spray nozzle’s performance and the consequence on your manufacturing process and the quality of your final product.

Choosing the right spray nozzle or humidifier is crucial for your manufacturing process, the quality of your end product, and your productivity by reducing your costs.

Performance of Ikeuchi products vs. copy products

If nozzles have burrs at the orifice due to an imprecise tooling for example, then you can be sure that you will have an inconsistent performance.

Burrs and streaks in the spray pattern have impacts on the spray pattern, the spray distribution, the impact strength, and the water consumption.

When one nozzle has a low performance, the results in a multi-nozzle arrangement will have an even worse performance.

If you use a copy product of our Dry Fog humidifier, the consistency of the water droplets size is uneven. Therefore, you are risking your production by getting it wet. You will also increase your cost by consuming more air, needing more maintenance and replacement due to lower-quality parts.

Risks of using spray nozzles of poor quality

A spray nozzle with a production error will have an uneven water density and impact which means for you:

- Larger amount of water consumption

- Insufficient performance

- Easily clogged nozzles

- Increased in running cost

- Poorer quality for your final product

- Increased replacement time of the nozzles

Guarantee of performance as a spray and air nozzle manufacturer

As a nozzle manufacturer, we take upon our responsibility to provide a high-quality product to our customers. Therefore, we always test the quality of one nozzle per batch of production to ensure we always deliver high quality.

We officially guarantee the performance of our nozzles in terms of:

- Spray capacity

- Spray angle

- Spray angle tolerance

Advantages of Ikeuchi spray nozzles

Spray performance

Our spray nozzles deliver a best-in-class equal spray distribution.

Our spray come with a guarantee for the promised spray angle.

We provide a guarantee for our spray nozzles in terms of spray capacity, angle and spray angle tolerance.

Sustainable

Due to the combination of equal spray distribution, perfect spray angle and high wear resistance, our spray nozzles lead to a lower water consumption.

Due to the combination of equal spray distribution, perfect spray angle and high wear resistance, our spray nozzles lead to a lower chemical consumption.

Due to the design and strict manufacturing process of our nozzles, they have less risk of clogging.

Made in Japan

Our nozzles are produced in-house at our Japanese factories. This ensures the highest quality standards in the world.

Our strict manufacturing process end with a thorough quality check to ensure that our customers only reveive the highest quality.

Ikeuchi Japan was founded in 1954 and has more than 70 years of experience in the development and manufacturing process of spray nozzles.

Related articles

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”