Air Blower Driven Nozzles – Low pressure

As a category of IKEUCHI technical air nozzles, we developed our products to maximize blowing efficiency. Indeed, the wide range of models within each series offers the possibility of choosing the most suitable air nozzle for each application, optimizing the required blowing force and airflow. This complete product design contributes to a better control of the blowing accuracy of each application.

Flat, compact, round, long and thin slit, we have several shapes of nozzles for different applications: drying, blowing off particles, cooling, cleaning, air curtain, etc.

We divide our air nozzles into two categories: compressed air driven nozzles and air blower driven nozzles. These categories represent each way that the air can be supplied to the nozzle and they can be used for different installations. Each of them has unique properties and will answer better to one kind of application.

The air blower driven nozzles do not require the usage of compressed air to perform.

Why are Blowers more energy efficient than compressed air?

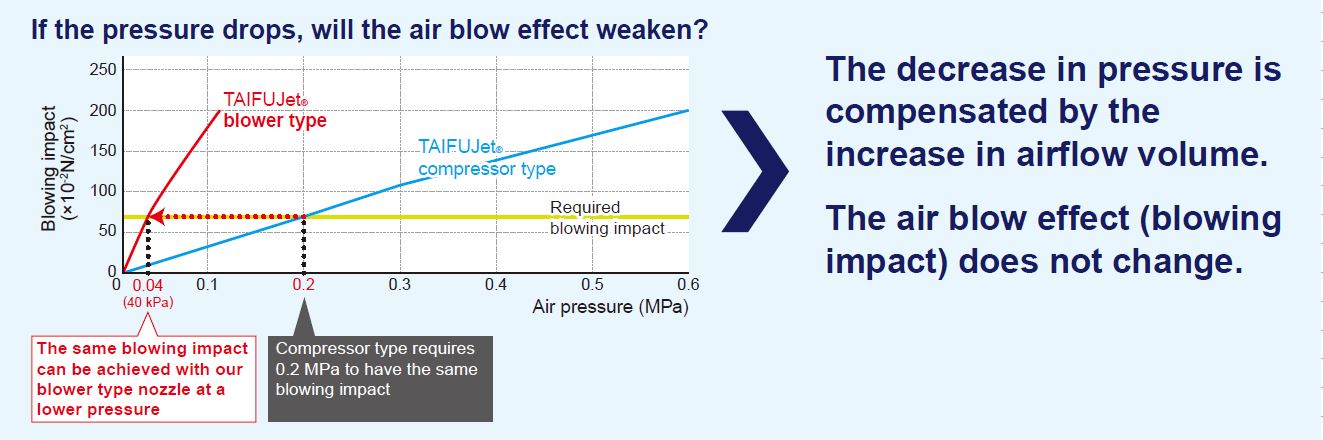

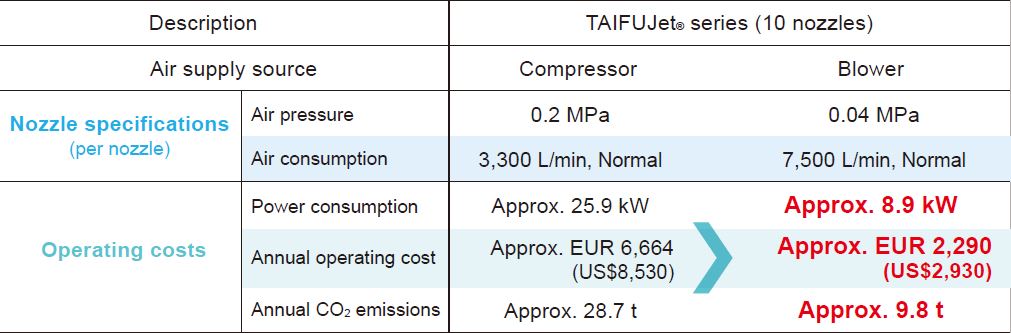

The air blower nozzles or low-pressure air nozzles use the outdoor air at normal pressure to be efficient. They are very cost-efficient and require little initial costs compared to compressed air nozzles. Without the need of installing a compressor nor using compressed air to perform, the air blowers will save on energy cost and maintenance. Utilizing air blower nozzles lowers the energy consumption by 2/3 compared to compressed air nozzles, without a decreasing in performance. The outside air pressure is optimized to efficiently blow with enough force for application such as pinpoint cooling blowing off particles, drying, etc.

Making the switch from compressor to blower reduces the operating costs by approximately 66% (results vary depending on the conditions). Customers who use blowers benefit from cost reductions and dramatically power consumption reductions.

Note:

The annual operating cost is calculated using an annual operating time of 2,000 hours (approx. 8 hours/day) and an electricity rate of EUR0.13 (USD0.17)/kWh. Power consumption is calculated with a motor efficiency of 0.85 and CO2 emissions of 0.555 kg CO2 per kWh.

What is the noise level of blower nozzles?

The second benefit of using air blowers is the reduction in noise level. Our air blower nozzles follow the requirement of the OSHA regulation to reduce the overall total noise level exposure (8 hours workday exposure to noise level below the average of 85 dB(A)). Although our compressed air nozzles perform with a lower noise level (ca. 66 – 87 dB(A) depending on the model), our air blower nozzles have a noise level of between 75 to 94 dB(A) at 0.3 MPa (ca. 3 bar) depending on the model. Slit type of air knives will have a higher noise level (e.g. 90 dB(A)) than a flat fan nozzle (85 dB(A)) or round spray type (86 dB(A)).

Depending on your application and industry, you can find the right air nozzle among these low-pressure range of nozzle:

- Flat fan nozzles: TF-BF series, noise level of 85 dB(A) at 0.3 MPa

- Round nozzles: TF-BR series, noise level of 86 dB(A) at 0.3 MPa

- Air knives:

- TF-BPF series, noise level of 106 dB(A) at 0.3 MPa for the plastic version

- SLNB series, noise level of 90 dB(A) at 0.2 MPa (for a slit length of 800 mm)

The importance of the choice of material

Each series offers the possibility to have the nozzle in different material: in plastic, stainless steel, or aluminium for a higher heat resistance. The standard and optional materials available for nozzles are shown in the material section of each nozzle series’ product catalog.

For more information about the best choice of material, have a look at the table of properties for each material here.

Industrial applications

Each model has a different flow of air, rather the spray pattern blows in a fan shape, pinpointing with a round shape or a more long and thin spray like blades. Depending on the area of treatment, the sizes of the nozzle will influence the choice of the model.

- For a flat fan shape spray, the TF-BF42 nozzle has an opening of 42 mm wider for a high impact of air stream at low noise level.

- For a round jet air booster, the TF-BR series is designed with six orifices to generate a powerful high impact air stream while saving energy and generating low noise level.

- For a longer flat spray distribution that can cover a single area up to a 1,596 mm of width, slit nozzles like TF-BPF and SLNB series are more suitable, especially in confined spaces.

At IKEUCHI, we have determined the fundamentals to select the most suitable nozzle for your application based on their characteristics. When selecting the nozzle, we advise you based on your required spray angle, spray capacity, optimum spray pattern, and spray distribution.

If you have technical question about nozzles, need advice to choose, or request a quote,