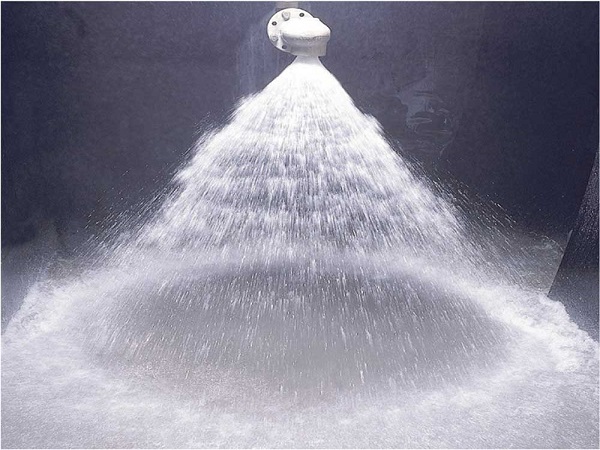

Hollow Cone Spray Pattern Nozzles

Hollow cone spray pattern nozzles are hydraulic nozzles. We designed our hydraulic nozzles to spray water or other liquids. The other hydraulic nozzles are: flat spray pattern, full cone pattern, solid stream pattern. These categories represent different spray patterns and each of them will be suitable to your needs, depending on the application and the results you are looking to achieve.

With similar pressure, spray capacity and spray angle, the mean droplet size of hollow cone spray nozzles is the smallest among all hydraulic nozzles. By reducing the mean droplet diameter, it increases the total surface area of the spray liquid, which has a great effect on transport phenomena of materials, such as chemical reaction, absorption, adsorption, etc.

By taking an individual approach to each nozzle from the hollow cone spray nozzle spectrum, Ikeuchi applied specific characteristics and designs to these products in order to be suitable to various applications.

Before presenting the applications of our hollow cone nozzles, we will show how these nozzles are segmented and based on what criterion. Our hollow cone spray pattern nozzles contain the following range of products that are divided based on the mean droplet diameter size:

- Fine fog nozzles (-100μm)

- Semi-fine fog nozzles (-300μm)

- Light rain nozzles (+300μm)

How to choose the suitable hollow cone nozzle for your application?

A distinguishing criterion of the above-mentioned categories of hollow cone spray pattern nozzles is the mean droplet diameter size. The droplet diameter of a nozzle will influence the pattern of spraying and the type of application for which this nozzle will be applicable to.

In the case of the fine fog nozzles, they provide a spraying capability of fine atomization. The semi-fine fog nozzles have a larger mean droplet diameter than the fine fog nozzles and, as their name describe them, are spraying a semi-fine fog.

On the other hand, the light rain nozzles can spray the largest droplets. Based on their differential characteristics, they are able to suit other specific applications, such as cooling within the production of metal.

Another characteristic of the light rain nozzle is the fact that they have a higher spray capacity, as compared to the other 2 categories of hollow cone spray nozzles.

Although the hollow cone spray nozzles can spray fine fog, they do not require a compressor, or compressed air, as in the case of the pneumatic nozzles. This might come in handy when it is required to spray a fine atomization and the installation does not have or require a compressor. By doing so, the installation process is easier to implement, and it is energy and cost saving, as a compressor requires electricity. However, for certain applications such as cooling, and where a large number of nozzles are required, variable frequency drives or variable speed drives can assit for a better control. These drives are suitable for cooling, as you can adjust the mist output flow according to your cooling need.

How is this spray pattern achieved through nozzle design?

As mentioned in the above paragraph, hollow cone nozzle produces a fine fog like pneumatic nozzle but without the help of compressed air. This is possible thanks to their inner design.

Each nozzle will have a special interior design to achieve different spray pattern. A simple whole will create an unshaped flow of liquid (e.g. a hole in a pipe) for which you cannot control the efficiency of the spray and its impact. Therefore, each nozzle series has a different design internally and at the orifice in order to produce the desired spray pattern. You can see from the nozzle orifice and the presence of a whirler or not what spray pattern the nozzle will produce.

Hollow cone nozzles are unique as, thanks to their internal design, they can produce the finest atomization among hydraulic nozzles. It makes them popular among customers who wish to cool down without the usage of a compressor.

Applications of hollow cone nozzle

Thanks to their high range of possibilities, we have a good solution to a lot of applications:

- cleaning;

- spraying water or chemicals;

- cooling and washing gases;

- cooling of fruits and vegetables in supermarkets and cold-storage production department;

- humidifying and chemical reactions;

- paper or metal trimming, etc.

Sometimes nozzles can be used for cooling in refrigeration equipment. However, it is important to make sure the material chosen can withstand the cold temperatures. Conditions in traditional refrigeration system can damage or break the nozzles. Therefore, we advise you to always contact our sales engineers to assess your need and determine the right nozzle for you.

In order to verify the quality and efficiency of products and maintain them at a high standard, Ikeuchi has implemented various testing stages within the production process. Choosing the right nozzle for your application is important in order to prolong the lifetime of the nozzle, increase your productivity and boost energy efficient measures. Our hydraulic nozzles have a performance guaranty (for standard pressures), therefore, helping you with making the right decision for energy savings.

In case of requiring more information, on each product page there is a general description that emphasizes the specific characteristics of each product, and also the applications that are optimal for a particular type of nozzle. Moreover, there are products that have a video attached on the product page. By doing so, you can observe the flow rate of the spray, the pattern and the distribution of the product as a virtual exposition.

At IKEUCHI, we have determined the fundamentals to select the right nozzle for your application based on their characteristics. When selecting the nozzle, we advise you based on your required spray angle, spray capacity, optimum spray pattern, and spray distribution.

If you have technical question about nozzles, need advice to choose, or request a quote,