Livestock

Disinfection in chicken hatch incubators

Process

Issues in chicken incubators without disinfection:

- Once micro-organisms penetrate the shell, they reach the membrane within minutes and are resistant to the disinfectant

- High chicken mortality and poor chicken growth

- Decreased or uneven chicken hatch

- Spread of bacteria in membranes

Solution: Automatic disinfection before hatching process

Disinfection is part of the basis for running a successful hatchery. If just one contaminated egg should crack within the incubator, it could jeopardize the entire batch. Bacteria may spread to other eggs or newly hatched chicks.

It is very important to disinfect the eggs after they have been laid.

Once micro-organisms penetrate the shell, they reach the membrane within minutes and are resistant to the disinfectant. The eggs should also be disinfected before they enter the incubator during the last days before hatching.

Example of Systems / Products used for this solution

Hydraulic nozzles: KBN series KB series

Solutions

Benefits

- Higher hatch rate

- Lower mortality rate

- Formalin-free disinfection

- No risk of overdosing

KBN series hydraulic nozzle

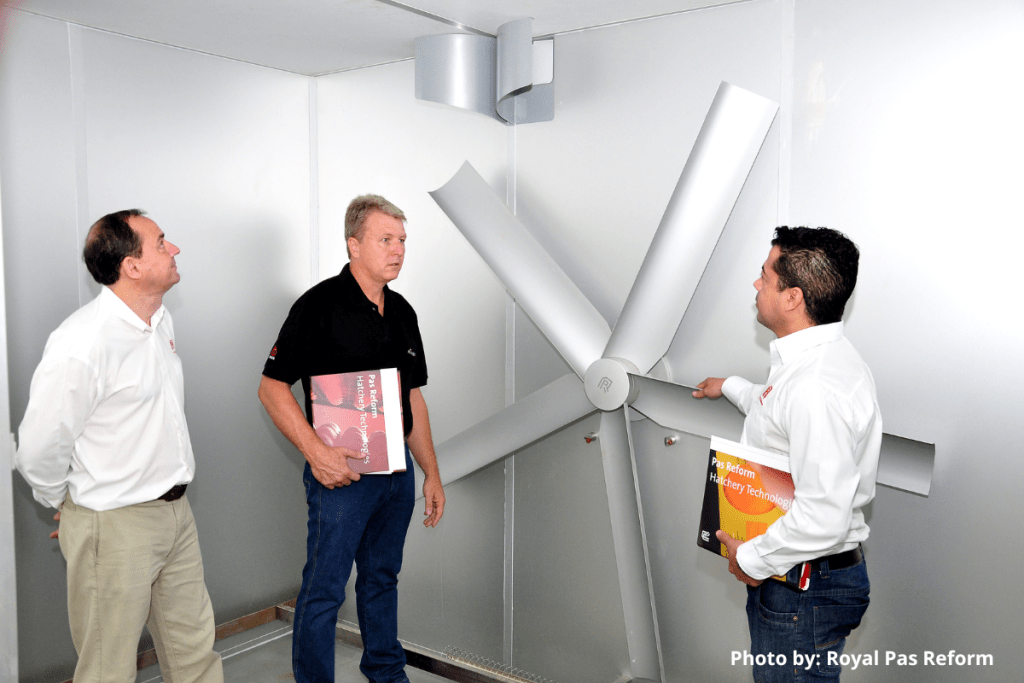

Example of how our KBN series nozzles were combined with the hatch incubator of Royal Pas Reform. The two nozzles can be seen just below the rotors.

Related articles

To better understand the importance a controlled humidity level indoor, here are some articles we’ve covered:

- Effect of lack of humidity

- Factors that affect the control of the humidity and its level

- The right humidity level for each industry

A controlled humidity level indoor will help increasing the production and reaching the quality each process wants. In additional, there’s a positive side effects for the companies reducing the sick leaves. Controlling the humidity level will also create a better working environment, reducing the absenteeism rate as the working environment becomes less enclin for virus to spread.