Applications

Humidification against electric static discharges

Overview

Electric static discharge (ESD) and humidity are interconnected. Humidity levels is a factor that has a direct influence over ESD and various electrical potential occurrences of static electricity. Before looking at this relationship between humidity and statistic electricity, and providing a clear definition of humidity, let’s review the aspects of static electricity.

What is static electricity?

We can all relate to the common life experience of a static electricity discharge (or static shocks), which results in a “shock sensation”, a slight noise of a spark and sometimes the spark can even be visible. This discharge of energy is caused by a charge separation.

When charged particles are transferred from one body to another. For example, if two objects are rubbed together, especially if the objects are insulators and the surrounding air is dry, the objects acquire equal and opposite electric charges and an attractive force develops between them.

In this process, one of the objects will lose its electrons (-) and will thus have a positive charge (+), while the other will have negative charges.

When a substance or an object become unbalanced in electrons and protons, it will lead to the occurrence of two phenomena that participate in generating static electricity:

- Contact charging is a phenomenon in which two objects approach and come into contact with each other, causing a substance to have a charge to either a + or – pole.

- The friction charging phenomenon occurs when materials are not just in contact, but when a friction is created by rubbing them against each other. The material becomes then charged to the + or – pole and static electricity is generated.

Why humidity matters

In a humid environment similar to the status of the bathroom while taking a bath, there is a high level of moisture contained in the air. In this case, static electricity will escape into the atmosphere through the buildup moisture without accumulating and charging itself on the surfaces of the objects.

At what humidity level does static electricity occur?

Electrostatic discharges happen when the humidity is low, which is the case when the humidity is 30% or lower. A safe humidity level is generally around 40-60%, depending on the application.

Does weather affect static electricity?

Static electricity is predominantly worse during the wintertime, as the air is more dry in this period, but it can occur all year round. The lack of moisture in the air leads to a level of dry humidity, which generates or enhances the flow of static electricity.

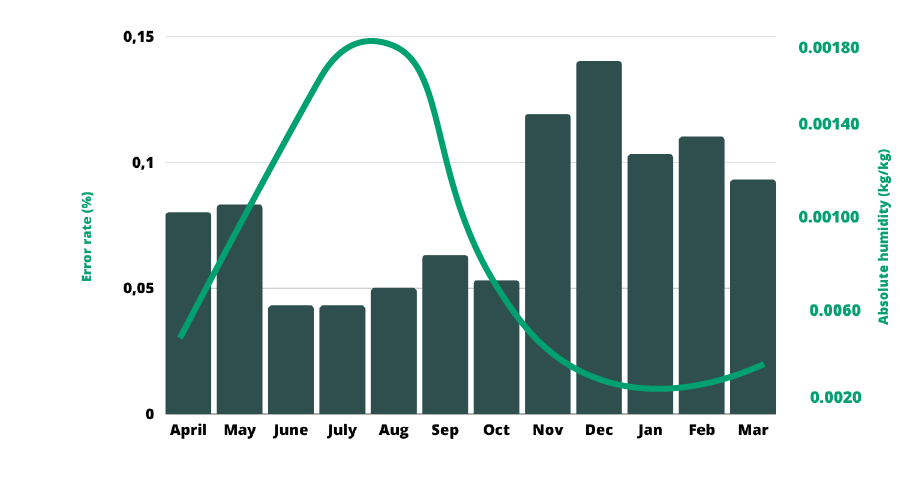

Below it can clearly be seen how the error rate increases as the humidity level drops.

Consequences of static electricity (ESD) in a production facility

Unprevented ESD can have a number of consequences for a production facility:

- Device destruction

- Fire ignition

- Quality issues

- Explosion risk

- Product defects

- Mounting errors

Solutions

Humidification and ESD prevention

The solution to suppress and prevent ESD is to increase the humidity level indoors. Keeping a proper humidity all year round helps the generated electrostatic to be quickly dispersed and released into the atmosphere.

Dry fog Humidification system for ESD prevention

The AKIMist humidifier is a unique Japanese invention which offers full control on the humidity levels in a factory. It is an adiabatic humidifier, which means that it increases humidity by adding cold water to the air.

AKIMist is known for its non-wetting abilities as the droplet size is less than 7.5μm. This means that the droplets are so small that they will bounce back without bursting on any surface. This is a very convenient ability in a factory with expensive machinery and materials which cannot get exposed to water or condense.

At the same time, adiabatic humidifiers are very energy-efficient and it uses 80% less energy that conventional humidifiers.

Benefits of AKIMist®

- Prevention of ESD

- Reduction of errors and scrap

- Productivity improved

- Quality stabilized

- Energy saving

- Less maintenance frequency

- Easy to install

- One unit can cover a large area

- Accurate control

- Japanese technology

Case studies

- Case Study of an installation:

- Customer Testimonial: Minebea Slovakia s.r.o.