Industrial Tank Cleaners

As part of our one-fluid nozzle (hydraulic), we offer tank cleaner solutions.

To clean tanks, containers and vessels is often considered as a manual job. However, in several manufacturing industries like the food industry, using tank cleaning nozzles became more and more popular. One of the major benefits is not only the high efficiency of the cleaning but especially the reduction in operating costs (less time spend on cleaning manually by the operators).

From the standard shower ball to 3-dimensional cleaning nozzles, we have 7 different series of tank cleaners:

- ES series

- ES-PTFE series

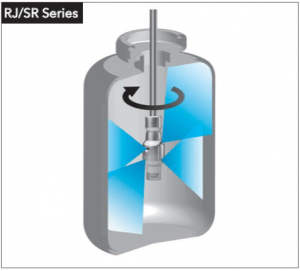

- SR series

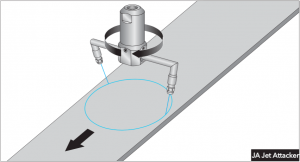

- JET ATTACKER series

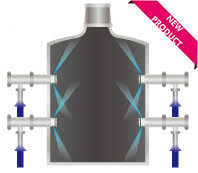

- JA-3D series

- Rotary Jetter series

- SWB series

We designed these nozzles to answer to any situation an industry can face, when in need of cleaning its tanks and containers. It allows you to maintain your equipment at its highest operational level. We have large-scale tank cleaners, low-pressure tank cleaners, and rotating tank cleaners.

Industrial Tank Cleaning Nozzles

From our current variety of 7 series of tank cleaning nozzles, Ikeuchi strives to provide solutions for the tank cleaning industry based on the numerous requirements of our customers. Some of our tank cleaners are focused on streaming jets of water that ensure a highly efficient performance in cleaning. Other types are indicated and suitable for the cleansing of vessels.

Moreover, cleaning the interior of storage tanks has always been considered a challenging task due to the edges or corners that are hard to reach. However, one of our products, thanks to its design capabilities of the spraying distribution to 360° angles, can efficiently cleanse the places hard to reach and is covering all of the tank’s areas.

Tank cleaning solution resistant to chemicals

The materials from which our tank cleaning nozzles are developed are resistant to various chemicals. The majority of our tank cleaning nozzles are manufactured either from stainless steel or PTFE plastic. Both of these materials are highly resistant to chemical substances, providing and ensuring the necessary safety regulations, for cleansing or sterilizing the confined space entry tanks. By being chemically resistant, this also leads to a reduction in the cost of maintenance.

In the case of an inflammable or possible hazardous substance, such as a fuel oil tank, using tank cleaner nozzles will help manufacturers to comply with the OSHA regulations by removing the manual tank cleaning operations and, thus, creating a safer working environment. Another suitable option for replacing the manual tank cleaning is through robotic tank cleaning, which can also result in creating a secure working habitat.

Multiple Sizes of tanks – designated for specific tank cleaning project

Based on the industry applicability of the tank cleaning nozzles, Ikeuchi can assist with supplying nozzles that will be suitable for a concrete and specific tank capacity. The spray distribution of tank cleaning nozzles can vary from a small diameter coverage (e.g.:0.45-0.9 m) and can differ to reaching intermediate (e.g.: 3,75 m), and larger dimension, depending on the model and type of nozzle. The tank cleaner nozzle’s jet dimension will also influence the nozzles spraying capacity of Liters/minute (Gallons of water/minute – for the UK).

The tank cleaning industry requires a thorough, efficient and effective service through the delivery of qualitative products. That is why our tank cleaning experts can assist and guide our clients with information in regard to the specific type of tank cleaning nozzle that:

- is necessary for their need,

- applicable for a certain volume, capacity,

- and resistant to a particular type of chemical substance.

At IKEUCHI, we have determined the fundamentals to select the right nozzle for your application based on their characteristics. When selecting the nozzle, we advise you based on your required spray angle, spray capacity, optimum spray pattern, and spray distribution.

If you have technical question about nozzles, need advice to choose the right product for your tank cleaning project, or simply request a quote,