Solid Stream Pattern Nozzles

Solid stream pattern nozzles are hydraulic nozzles. We designed our hydraulic nozzles to spray water or other liquids. The other hydraulic nozzles are: flat spray pattern, hollow cone pattern, full cone pattern. These categories represent different spray patterns and each of them will be more suitable depending on the application and the results you are looking to achieve.

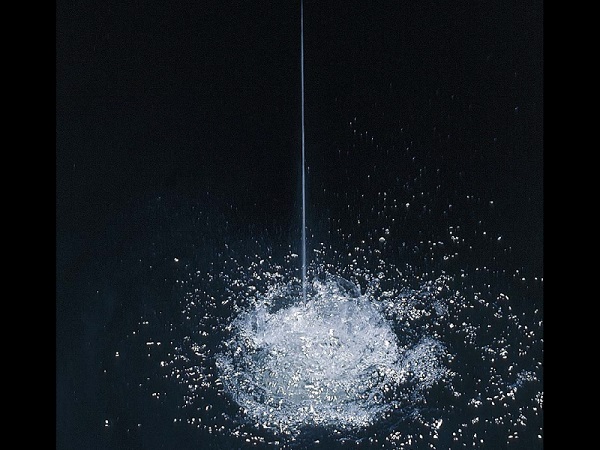

Solid stream spray pattern nozzles are designed to produce a compact, solid stream of liquids to spray. This is not to be confused with the spray fog nozzle. The nozzles that produce fine and semi-fine fog can also be hydraulic (such as in the Hollow Cone spray nozzle category) or pneumatic nozzles. Thus, the solid stream spray nozzles distinguish themselves from the flat jets and cone type pattern nozzles (hollow and full), not only through their spray pattern, but also their characteristics and suitable applications.

They might be the simplest form of nozzles since their design is very straight forward. However, they are very useful and practical when high impact cleaning is required, or for trimming/ cutting applications, especially in the paper industry.

Moreover, the solid stream jet nozzles are organized into 4 sub-categories, as follows:

- Standard solid stream jet nozzles

- Convex Round Inlet solid stream jet nozzles

- Paper Trimming solid stream jet nozzles

- Special Solid Stream Jetnozzles

How to choose the best solid stream nozzle for your need?

The reason why these nozzles have been segmented into subcategories is due to their application, but also their features and characteristics. One of the main characteristics of the solid jet spray nozzle is the applied standard pressure. This can vary from 0.3 MPa, and can go up to 3 MPa depending on the nozzle model within that subcategory.

Another point to be taken into account when selecting the right type of solid stream nozzle is related to the flow rates. The flow rates are in direct correlation with the standard pressure that a nozzle is required to operate. A minimal pressure drop can assist into delivering and generating a higher flow level of solid stream jet or on the contrary an inconsistent spray. The nozzles also come in different sizes, suitable for different pipe connections.

Applications and usage of solid stream nozzle

The characteristics’ comparison, that distinguish the products, lead to assigning the subcategories of solid stream nozzles to a specific type of application.

Thanks to their high array of possibilities, the solid stream nozzles provide a wide variety of optimal solutions to your applications, from which we can mention the following:

- cleaning;

- spraying water or chemicals;

- cooling;

- paper or metal trimming, etc.

These applications and many more are possible thanks to the unique design and innovative process of Ikeuchi. The solid stream nozzles are manufactured from stainless steel, however, some of the models have the benefit of being designed from a special material for which Ikeuchi is renowned, and that is ceramics. In certain cases, advanced ceramic materials have been utilized to produce whole nozzles and orifices only.

One of the main reasons for utilizing ceramic nozzles, is that they are ideal for situations when abrasive-wear occurs. The spray nozzle head is always exposed to abrasion due to high velocity flows. If the liquid to be sprayed also contains slurry or impurities, abrasive wear will occur more quickly. Our spray nozzles with ceramic material have an enhanced toughness, which slows down the wear of the nozzles compare to standard steel nozzles.

The spraying products that have been manufactured either with a ceramic nozzle orifice or full ceramic nozzle: CP series, CM series, 2CP series, 7 CP series, SO-CM series, UT+CP series, CRP (AL99) series, CMP-T series, CTM series.

If you would like to encounter more details in regard to ceramic nozzles’ benefits and applications, please visit the Ceramic Nozzles page.

In case of requiring more information, on each product page there is a general description that emphasizes the specific characteristics of each product, and also the applications that are optimal for a particular type of nozzle.

Moreover, there are products that have a video attached on their product page. By doing so, you can observe the flow rate of the spray, the pattern and the distribution of the product as a virtual exposition. However, our experts are always at your disposal, so do not hesitate to contact them in case of requesting for additional information over the product or price.

At IKEUCHI, we have determined the fundamentals to select the right nozzle for your application based on their characteristics. When selecting the nozzle, we advise you based on your required spray angle, spray capacity, optimum spray pattern, and spray distribution.

If you have technical question about nozzles, need advice to choose, or request a quote,