Applications

Disinfection of facilities with Fog

Overview

Disinsfection is an effective measure against the spread of airborne viruses. As a safety measure in countering the spread of viruses, installing the proper disinfection systems can come in handy in protecting your employees and your business.

Purpose of facilities’ disinfection

- Sterilization of surfaces

- Elimination airborne contamination

- Prevention of virus and bacterial spread

- Maintaining healthy environment

- Disinfection of public areas, working spaces, communal rooms, manufacturing facilities

- Disinfection of facilities without damaging / wetting the production and people thanks to small droplets sprayed

- Sprayed droplets small enough to effectively destroy viruses and bacteria

- Combined with an efficient disinfectant chemical solution to sterilize

Solutions

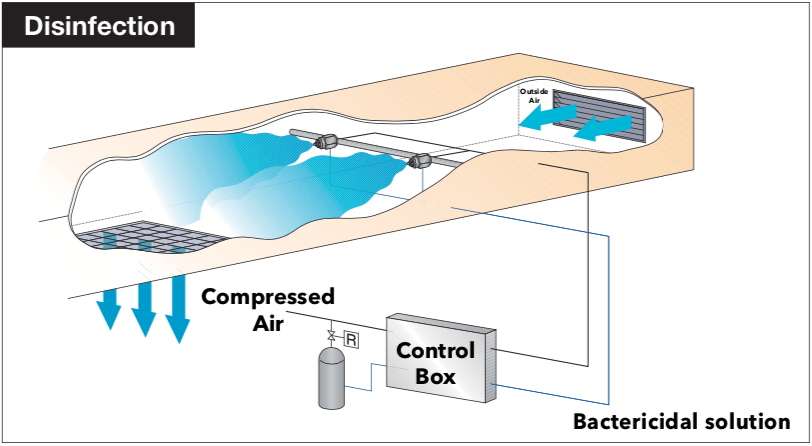

Disinfection systems from extremely fine fog to Dry Fog

Our Dry Fog unit, AKIMist®, can disinfect a room while increasing the humidity level at the same time. It sprays a dry fog with a mean droplet diameter of less than 10μm. The droplets are so small that they will bounce back without wetting any surface. Hence the name dry fog.

Research has shown that humidity has a significant effect on the spread of viruses. The higher the humidity, the less the virus can spread. The higher level of humidity will suppress contaminated droplets to the ground.

On-the-go disinfection: SETOV

Our extremely fine fog unit, SETOV, is a convenient ready-to-use disinfection solution with a 20 L tank. This unit sprays an extremely fine disinfection fog with a mean droplet diameter of approx. 15 μm.

The SETOV spray unit is applicable for indoor humidification or moisture conditioning in indoor facilities such as:

- Public facilities

- Commercial facilities

- Manufacturing processes

- Corridors, offices, restrooms, and other indoor facilities

What benefits do you receive from IKEUCHI’s industrial disinfectant spray machines?

Benefits

- Spot disinfection or ambient (full room)

- Chemical resistant products

- Low cost – operating costs are one fifth compared to conventional steam atomizers

- Easy to operate and maintain

- All-in-one solution with built-in compressor

Additional line-up for disinfection of objects:

In addition to spatial disinfection with our fog sanitization units, we offer hydraulic nozzles for:

- Hand disinfection

- Disinfection gate for workers: plastic nozzle

- Disinfection gate for vehicles

VEP – JJXP : Full cone top, flat spray size on the conveyer belt

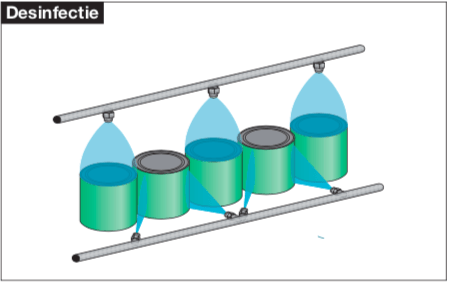

BIM series 45′ in a compressed air ventilation system

Success Stories

Our products are not only recommended for the industrial segment, as they can also serve their purpose in public buildings and spaces. In the entire Europe, thanks to the collaboration with Mendizza Water & technologie and RealTime Technologies, our disinfection unit are installed in offices, supermarkets, hospitals, and public areas to break down bacterial and viral loads from surfaces. Portable and easy to handle, they are ideal for the disinfection of facilities such as hospitals and public spaces.

[WARNING] As we do not provide the disinfectant liquid, please follow the instructions from the disinfectant provider as well as your countries’ regulations.

Disinfection in production hall (RealTime Technologies)

Disinfection in multiple indoor environments (RealTime Technologies)

Disinfection in shopping malls (Rentacs)