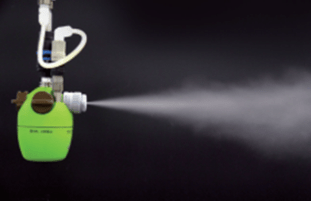

Industrial Humidification units – AKIMist®“E”

Anti-clog Dry Fog Humidifier

AKIMist ®“E” Seto Jet anticlog version

AKIMist ®“E” Seto Jet anticlog versionIndustrial humidification units are a very common use of pneumatic nozzles. It allows a precise and accurate way to monitor the temperature and the humidity level. Many factories need specific humidity characteristics to operate at their full capacity.

An industrial humidification unit does not only provide moisture control but also:

- Dust suppression.

- Electrostatic discharge prevention.

- Healthier working environment for the operators.

- Reduces the risk of virus spread.

- Possible to utilize for disinfection.

Humidification control is useful and even critical in a number of industries:

- Food and beverage

- Automobile industry

- Painting and coating

- Electronics and SMT

- Chemical and pharmaceutical industry

- Printing and paper production

- Textile production

Why is industrial humidification important in a factory?

- Product Quality: In certain manufacturing processes, especially those involving sensitive materials like paper, textiles, or wood, maintaining optimal humidity levels is critical for product quality. Humidification helps prevent issues such as cracking, warping, or dimensional changes in materials, ensuring that the final products meet quality standards.

- Equipment Performance: Many industrial processes and machinery function optimally within specific humidity ranges. Maintaining the right humidity levels can enhance the performance and longevity of equipment, reducing the risk of corrosion and wear on machinery components.

- Static Electricity Control: Industrial environments often involve the movement of materials and processes that generate static electricity. Low humidity levels can exacerbate static electricity buildup, leading to disruptions in manufacturing processes and potential damage to electronic components. Humidification helps control static electricity, ensuring smooth operations.

- Dust and Particulate Control: Humidification can help control airborne dust and particulates in factories. By adding moisture to the air, dust particles are less likely to become airborne, reducing the risk of respiratory issues for workers and maintaining a cleaner working environment.

- Process Control and Precision: Some manufacturing processes, such as those in the pharmaceutical or semiconductor industries, require precise environmental conditions. Controlling humidity levels is crucial in maintaining the accuracy and precision of these processes, ensuring consistent and high-quality production.

- Woodworking and Paper Industries: Factories involved in woodworking, paper production, and printing often require specific humidity levels to prevent issues like paper curling, ink drying problems, and dimensional changes in wood. Humidification helps maintain the ideal conditions for these processes.

- Material Conditioning: In certain industries, such as textiles, maintaining consistent humidity levels is essential for material conditioning. Humidification helps prevent issues like static cling, fiber breakage, and other problems associated with dry conditions.

Read more about the different types of humidifiers here

Read how to choose the right industrial humidification system here