Types of materials used

The materials used for spray nozzles vary greatly. Some nozzles material is highly resistant to chemicals while other material is highly heat resistant. The choice of nozzle material can have a significant impact on the efficiency and the lifespan of your nozzle, depending on the application. Therefore it is important to inform yourself about the different options before choosing a nozzle.

The types of materials used:

- Stainless steel

- Die-cast stainless steel

- Hardened stainless steel

- Brass

- Plastics

- Ceramics

- Aluminum

Advantages and disadvantages of materials used

Stainless steel

Stainless steel is an alloy of iron and carbon, with other elements such as chromium, nickel, molybdenum, vanadium, titanium. The most popular stainless steels for spray nozzles range between 303 to 316L. Stainless steel is resistant to high temperatures and can withstand temperatures between 400 ° – 800 °, depending on the type and time-span. Stainless steel is however not very corrosion resistant and should not be used when certain chemicals are involved.

Die-cast stainless steel

Die-cast stainless steel is equivalent to stainless steel. The main difference is that it is mass produced with a mold. Mainly larger spray nozzles are produced this way.

Hardened stainless-steel

Hardened stainless steel has a higher carbon content which makes it able to withstand even higher temperatures. Furthermore, is very wear resistant and the lifesspan of a nozzle is longer than for non-hardened stainless steel.

Brass

Brass is stronger and lighter than stainless steel. Spray nozzles made of brass do however have a slightly lower wear resistance than stainless steel nozzles.

Plastics

Spray nozzles made of plastic are cost efficient and generally have a high resistance to chemicals, depending on the type of plastic. Plastic is however not suitable for applications which require high temperatures.

Ceramics

Ceramics is a very strong and most wear resistant material for spray nozzles. It is highly resistant to most chemicals and can maintain its strengt up to 1400°C. Read more about ceramic spray nozzles here

Aluminum

Aluminum spray nozzles are not commonly used for industrial applications. Due to the softness of the material, the wear resistancer is not very high.

Resistance

The selection of a material will determine the type of resistance and endurance. The following four types of resistance are the most common ones that you can encounter when utilizing the nozzle in operating conditions:

- Wear resistance

- Chemical resistance

- Heat resistance

- Pressure resistance

Wear Resistance

Nozzle orifices are always subject to abrasion because they are constantly exposed to the flow of liquid at high speed. If a circulated liquid containing slurry is used, they will wear out faster.

Nozzles with a high wear resistance

Alumina Ceramics has a hardness of 9 on the Mohs scale, which is quite close to the hardness of a diamond (10). It can last 20–30 times longer than stainless steel nozzles and several hundred times longer than brass ones.

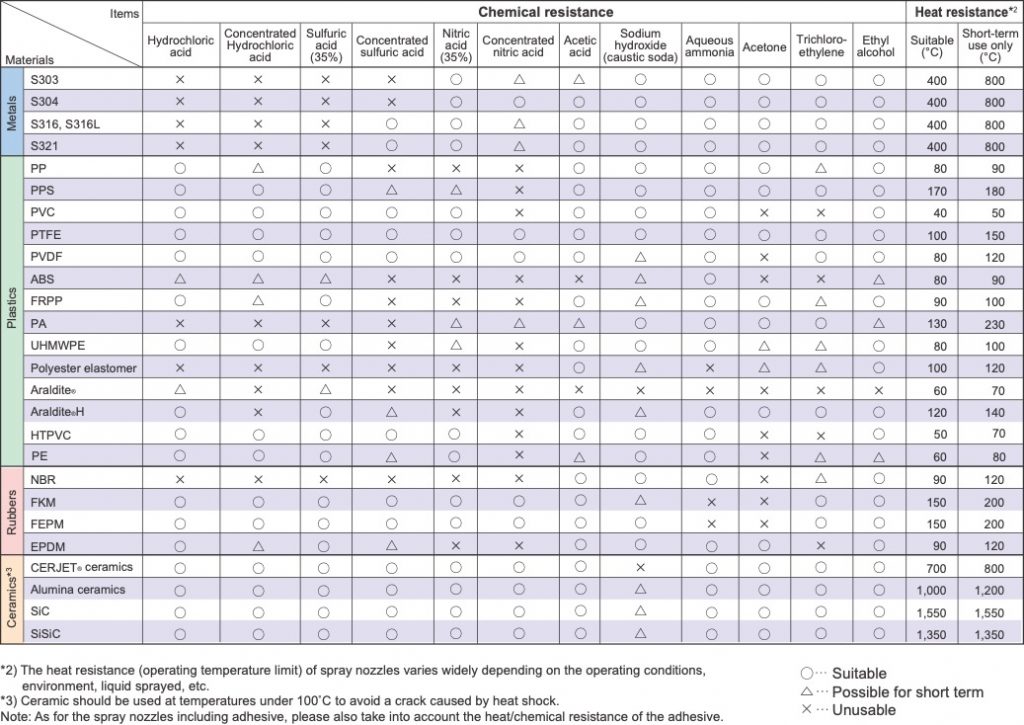

Chemical Resistance

In spraying chemicals or using spray nozzles in a corrosive environment, chemical-resistant materials must be used. Otherwise the spray nozzles will corrode at a quicker rate. The ceramic orifice has a high chemical resistance and is unaffected by almost all acids and highly corrosive chemicals, except hydrofluoric acid and alkali liquids of pH12 and over.

For the applications where adhesives or metal nozzle body materials (stainless steel) may corrode, we recommend our CERTIIM® nozzle with ceramic orifice inserted into injection-molded engineering plastic body. In addition to spray nozzles made of optional materials shown in this catalog, nozzles in other special materials are available on request.

Heat Resistance

The temperature that the spray nozzles can withstand varies depending on the liquid and ambient environmental conditions. Spray nozzles made of special materials are available for use at high temperature. CERJET® (nozzles with ceramic orifice inserted) may crack if abruptly cooled down from high temperatures (200°C). Nozzles made out of silicon carbide can withstand higher temperature than other types of material due to their application and type of liquid that is being selected. Please also consider the heat resistance of any adhesives in spray nozzle assemblies.

Pressure Resistance

Spray nozzles are thoroughly designed so that they can withstand the pressures shown in each table. However, depending on the system operation, water hammering may result in pressure increases of three to five times the spray pressure. Three important aspects which need to be taken into account when it comes to pressure and selecting the nozzle material are:

- the relationship between the droplet size,

- surface tension,

- and the viscosity of the sprayed liquid.

For use under high pressure, metal nozzles are recommened over plastic nozzles.

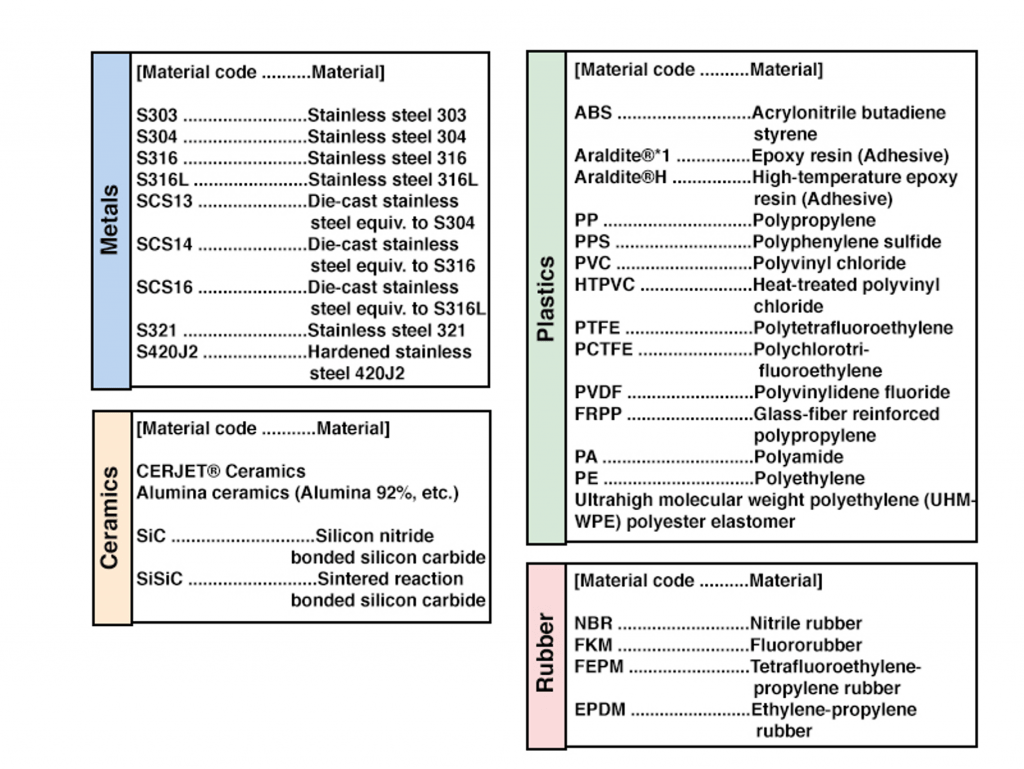

Below is an overview of the materials used in Ikeuchi spray nozzles. The second table provides an overview of the chemical resistance and heat resistance of each material.

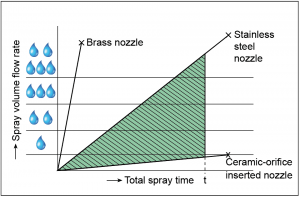

Consequences of a worn out nozzle

The illustration below shows the increase in flow of each nozzle due to a worn orifice. The shaded area shows the excess spray flow from a stainless-steel nozzle relative to the CERJET® during total spray time (t). To understand the damages of an excess spray flow, here are a few examples:

Examples

- If the spray liquid is agricultural chemicals, it could cause crop injury due to an overflow of liquid.

- In high-pressure cleaning, worn nozzles cause pump pressure to drop and the cleaning effect is rapidly degraded.

- As for flat spray nozzle, increased wear makes its spray angle narrower, while the spraying distribution of liquid becomes uneven.

Please consider the viscosity of a liquid before selecting the material of a nozzle. A certain material can be more adequate into handling a specific level of viscosity, which assists into maintaining and prolonging the lifetime of the nozzle.

More information

If you would like more information, there is a general description on each product page. Here you can find the specific characteristics of each product, and also the applications that are optimal for a particular type of nozzle.

However, our experts are always at your disposal, so do not hesitate to contact them in case of requesting for additional information over the product.

Please contact is if you have technical questions about nozzles, need advice to choose, or request a quote,