Hydraulic atomization

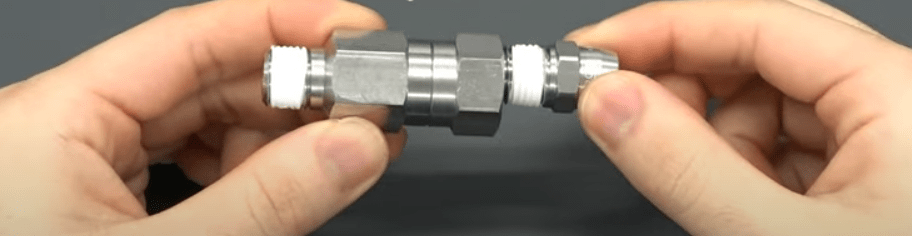

A hydraulic atomized spraying nozzle (single-fluid nozzle) only utilizes water supply and nothing else. The liquid is pushed through a tiny orifice at high pressure to reach the wanted atomization level.

Compared to pneumatic atomized spray nozzles,a hydraulic atomized nozzle will produce larger droplets due to the lack of compressed air. It is not possible to spray a dry fog or fine mist with this type of nozzle. This method can be used in cases where a larger droplet size is acceptable, for instance in rinsing or cleaning. The technique requires higher maintenance than a pneumatic nozzle due to the pressure on the relatively small orifice.

A hydraulic atomized spraying nozzle does however has a number of features compared to a pneumatic spray nozzle:

- Only water supply needed

A hydraulic atomized spray nozzle only needs water supply. No compressed air or other gas is neccessary. - More cost efficient

Hydraulic atomized spray nozzles are more cost efficient due to their more simple design.

From ultra-fine atomization to coarse atomization

Compressed air and liquid are mixed outside the nozzle. Hence, this type clogs the least. This is also classified into inner air type and outer air type.

Type of spray patterns

Spray pattern means the cross sectional shape of the spray. As illustrated, spray patterns are available in solid stream spray, flat spray, hollow cone spray and full cone spray. It is important to select a spray pattern suited for each application, thus, delivering the optimal nozzle performance.

Other factors which affect the spray performance

As can be seen in the illustration, spray performance can be affected by a number of factors from spray impact to wear resistance. It is important to choose a spray nozzle which fits well with the application it will be applied to.

Hydraulic atomized spraying nozzles with ceramic orifice

- High wear resistance

- High resistance to corrosion

- Can maintain its strength up to 1400°C

- Resistant to most acids and highly corrosive liquid

- Higher chemical resistance compared to metal

Advantages of hydraulic air-atomizing nozzles

- Only water supply needed

- More cost-efficient

We are here to help

Related articles

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”