Foam breaking

Foaming during the wastewater treatment process is a common issue in many WWTP. The foam can occur in several places from the aeration tank, the secondary clarifier and in the anaerobic digester. Foam is an issue as it can lead to a reduction of the system performance due to a reduction in oxygen transfer, a decrease in the concentration of biomass in the biological reactor, odor problems etc. In the worst case, the foam may even make the tank overflow and damage the surrounding equipment. Eventually, it will lead to an increase in operational and maintenance costs if not adressed (Collivignarelli, 2020).

Solution: Momojet®

Momojet® is an advanced type of spray nozzle which was developed specifically to break foam in WWTP. The spray nozzle has a high impact solid stream, which is powerful enough to break down the foam. This spray nozzle is also suitable for multi-nozzle setup when needed.

Momojet®

Momojet® is an advanced type of spray nozzle which was developed specifically to break foam in WWTP. The spray nozzle has a high impact solid stream, which is powerful enough to break down the foam. Momojet is unique due to its self-cleaning function.

Self-cleaning function

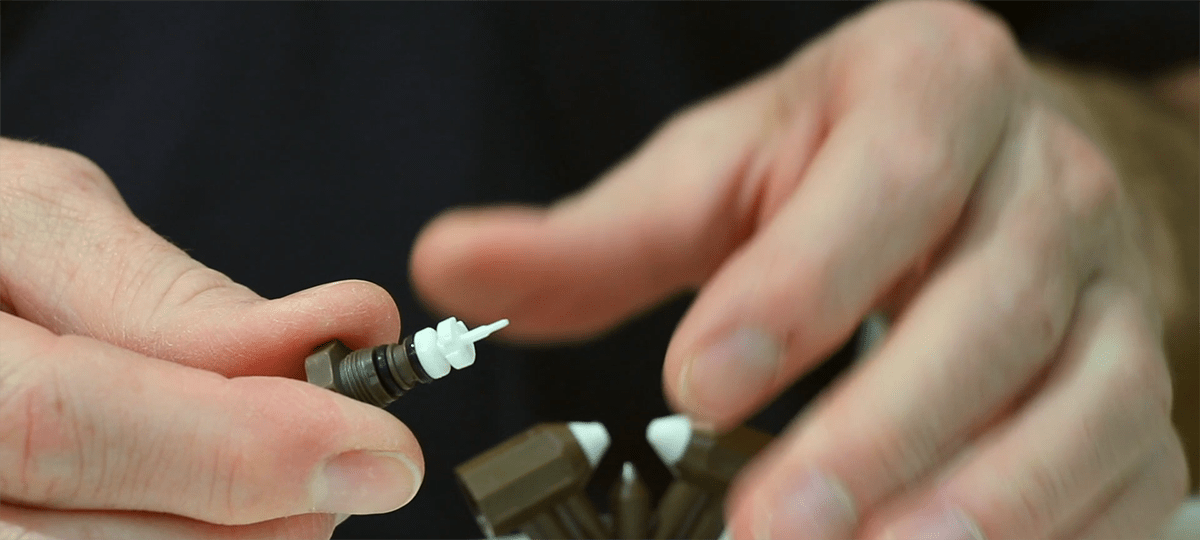

Momojet is unique due to its self-cleaning function. By changing the liquid pressure, a built-in spring moves the split nozzle tip up and down and opens the orifice for purging away foreign particles.

This purging function helps to reduce maintenance time and costs significantly as it happens automatically. It also increases the logevity of the spray nozzle and prevents the risk of clogging.

Here to help

Related articles

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”