Save energy and costs in your factory by optimizing your humidification system

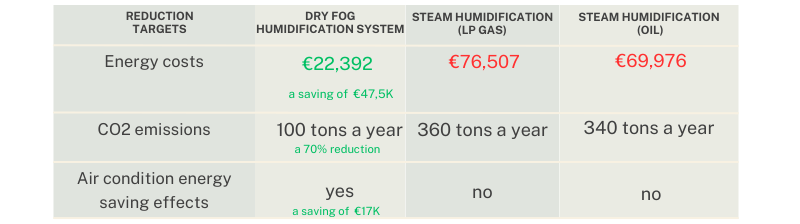

If you are looking for a way to optimize the energy use in your business and save money, it can be very profitable to look into your humidification system. There is a significant difference between steam humidification and dry fog (cold mist) humidification. The energy costs of running a dry fog humidification system like AKIMist® E is five times lower than a conventional steam humidification system.

Steam versus dry fog

Why is Dry Fog more energy efficient?

AKIMist is extremely energy-efficient and uses up to 80% less energy than conventional humidification systems.

AKIMist cools around 2 degrees while controlling the humidity level. It reduces 20% of the energy used for air-conditioning and thereby saves cost.

AKIMist can be used for spot humidification and be placed directly by the source of issue. This reduces the price significantly as only a few units may be needed.

1. Energy efficiency

Dry Fog humidification only uses 1/5th the energy that a steam humidification system does, which makes it the most cost efficient and sustainable choice. Due to the great savings on energy costs, the investment in Dry Fog can be returned within two years.

One of the most important differences between steam humidification and a dry fog humidification system is that a steam system cannot shut down in between. This means that a lot of energy goes to waste. A dry fog system, on the other hand, can automatically turn on and off whenever the humidity level drops below the limit. This means that a 100% goes into the factory and nothing is lost.

2: Cooling effect

Dry Fog humidification has the added benefit that it cools while it humidifies. This can reduce the energy costs from air conditioning significantly and improve the working conditions.

For steam humidifiers, air-conditioning works against their purpose and they will need to produce even more steam in order to maintain the wanted humidity level. The dry fog system works together with the air-conditioner and has a cooling effect. It can reduce 20% of the air cooling energy needed for the air-conditioning.

3: Spot humidification

Cost savings

Switching from steam humidification to Dry Fog humidification leads to a significant reduction in energy costs and CO2 and can be refunded within two years.

Our Dry Fog humidification solution; AKIMist®

Our AKIMist® humidifier, is a unique Japanese invention by Ikeuchi Japan, which offers full control of the humidity levels in a factory. It is an adiabatic humidifier, which means that it increases humidity by adding cold water to the air. AKIMist is known for its non-wetting abilities as the droplet size is less than 7.5μm. This means that the droplets are so small that they will bounce back without bursting on any surface. No risk of leakage or condensation. This is a very convenient ability in a factory with expensive machinery and materials which cannot get exposed to water or condense.

The AKIMist® “E” humidifier system provides a complete solution for ESD prevention. It is a total humidification system which can control the precise humidity level wanted with the installation of a sensor to the control panel.

AKIMist® “E” Dry Fog Humidifier

Our AKIMist®“E” spreads a Dry Fog that humidifies indoor environments without wetting due to its tiny droplet size around 7.5µm

Our global solution for saving energy and enhancing your production

Our engineers will offer you a personalized solution, based on your situation, your budget, and your requirements. Once you contact our team, we will study your case and come forward with a tailor-made proposal. We will accompany you through all the processes and help you install the best system for your company.

The Dry Fog humidifier AKIMist®“E” can both solve problems caused by static electricity and dust related issues at the same time. Due to its tiny droplet size around 7.5µm, the droplets will capture and bind with the dust particles. The droplets will weight them to the ground, preventing them from hampering the production process.

The AKIMist®“E” has the double advantage of also cooling the room by about 2 degrees. This leads to a great reduction in air conditioning costs during summertime compared to humidifiers like steam. The AKIMist humidifier only uses 1/5th the amount of energy that a steam humidifier consumes.

demo of AKIMist®

Experience AKIMist® Dry Fog technology in person at your facility our ours. It’s also possible to rent a portable unit for a testing period.

Related articles

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”