How to understand the thread coding?

Have you ever encounter a different coding of thread than you are use too when selecting a nozzle, a pipe or a fitting? If you are looking for a male or a female thread, parallel or tapered, depending on the country your are, the coding letters will be different.

For example, in America, the size of the nozzle’s thread should be mentioned in NPT (the American National Standard Taper Pipe Thread) following the ANSI B2.1-1968. In Europe, we will follow the ISO 7 and ISO 228 for the British Standard Pipe thread sizes.

Most common thread types worldwide

- ISO Metric thread: M

- Pipe thread: National Pipe Taper (NPT)

- Technical standards for screw threads adopted internationally: British Standard Pipe (BSPP [G]/BSPT [R/Rc])

- Unified threads: Unified National Thread (UNC/UNF)

For more explanation about their differences and their comparison, you can read the basic guide to thread types from Teesing company.

Our thread coding

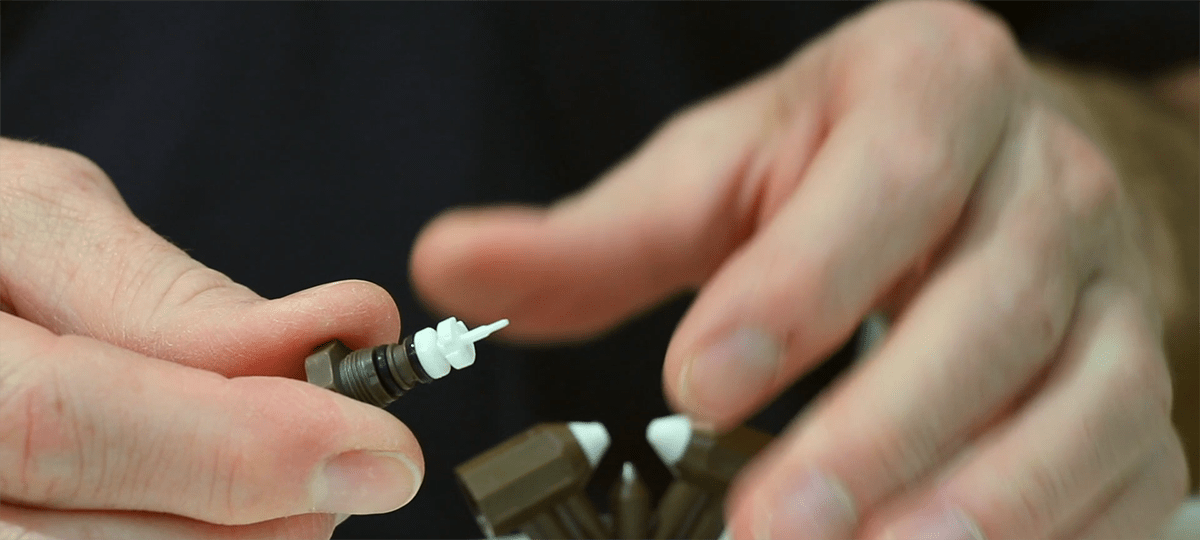

In our nozzle coding, when selecting a series, you will encounter different letters. We generally use the British Standard Tapered Pipe and Parallel following the ISO standard.

- M for male thread which is the equivalent of R, external taper (ISO 7)

- F for female thread which is the equivalent of Rc, internal taper (ISO 7)

- M, ISO Metric

- G, external and internal parallel (ISO 228)

Seek our advise on thread sizes

Don’t hesitate to ask our project engineers to help you find the correct thread size for your specific application and country.

Ready to help

We offer more than 42.000 types of spray nozzles. Ask our advise about anything related to spraying.

- Hydraulic spray nozzles

- Pneumatic spray nozzles

- Air nozzles

- Tank cleaners

- Humidity control

Related articles

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”