The importance of humidity control

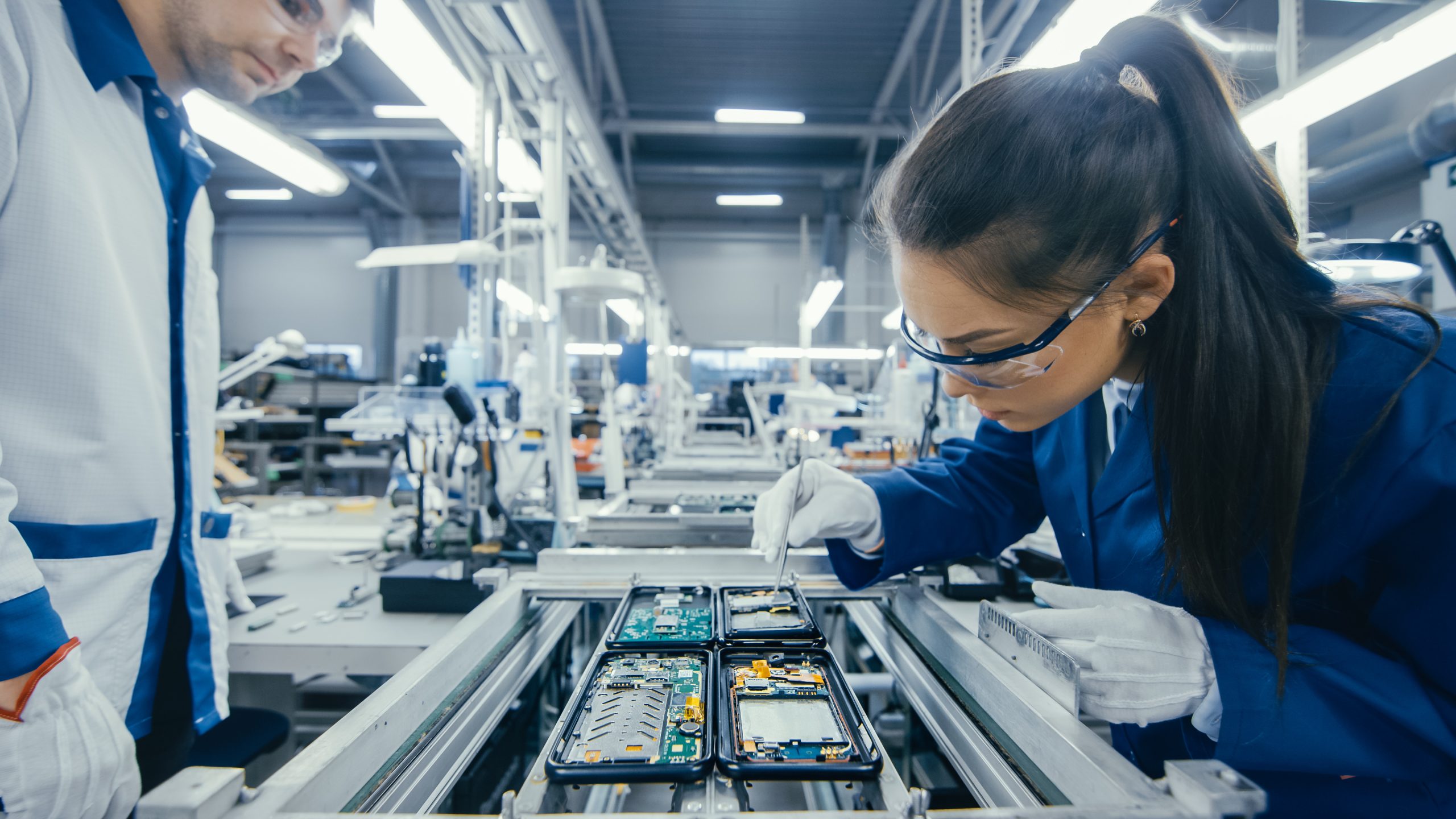

Humidity control is an important factor in maintaining cleanrooms. A cleanroom environment must be free from contaminants and suitable for the production of sensitive products such as pharmaceuticals, semiconductors, and medical devices.

Humidification is important in a cleanroom for several reasons:

Controlling static electricity:

Static electricity can be a major issue in cleanrooms, as it can attract and hold onto particles and contaminants. Humidity control can help to reduce the build-up of static electricity, which in turn reduces the attraction of particles and contaminants to surfaces and materials.

Controlling airborne particles:

Humidity control can also help to control airborne particles. Maintaining the appropriate humidity level can prevent particles from becoming airborne, and can also help to settle particles that are already airborne. This helps to keep the cleanroom environment free from contaminants.

Controlling microbial growth:

Humidity control can also help to control microbial growth. Many microorganisms thrive in low-humidity environments, so maintaining the appropriate humidity level can help to prevent the growth and spread of bacteria and other microorganisms.

Protecting materials and equipment:

Humidity control can also help to protect materials and equipment in the cleanroom. Low humidity can cause materials to become brittle, while high humidity can cause corrosion and rust. Maintaining the appropriate humidity level can help to protect materials and equipment from these types of damage.

Adiabatic humidifiers are a good choice for cleanrooms for several reasons:

Energy efficiency:

Adiabatic humidifiers do not require the use of steam or electricity to create humidity. Adiabatic humidifiers exploit the evaporation of water, atomised into small droplets, without adding any external energy. This makes them an energy-efficient option, which can be particularly important in a cleanroom where energy costs can be significant.

No risk of contamination:

Adiabatic humidifiers don’t have the risk of contamination compared to vaporizing humidifiers, for instance. This is due to open water baths, which can promote bacterial growth. Adiabatic humidifiers don’t have this, which makes them a safer choice for a cleanroom application.

Consistent humidity control:

Adiabatic humidifiers can provide consistent humidity control over a wide range of operating conditions. They are particularly effective at maintaining humidity levels in the low to medium range, which is often required in cleanroom environments.

Easy to maintain:

Adiabatic humidifiers are relatively simple in design and easy to maintain. They typically require only periodic cleaning and routine maintenance, which can help to reduce maintenance costs and minimize downtime.

Dual advantage:

Adiabatic humidifiers have the dual advantage of both humidifying and exploiting evaporative cooling to save on the costs of the air conditioning.

Versatility:

Adiabatic humidifiers can be used in a variety of cleanroom applications, including pharmaceuticals, electronics, and medical device manufacturing. They can be installed as standalone units or integrated into a larger HVAC system.

Issues caused by static electricity:

- Static electricity damages

- Particle adhesion on end products (product defaults

- Ignition source / explosion

- Ignition source / explosion

- Work environment problems caused by low humidity (sick workers)

- Dust explosion

- Contamination of components

- Adhesion and/or repulsion between objects

- Operation shut down, malfunction of the equipment / machines

The unforeseen costs

This generates costs for repairs of the products, cost for the maintenance of damaged machines, costs for the unsold damaged product and creates an unsafe working environment for the operators.

The lack of airborne moisture is the root cause of each of these issues. The dryness of the air enables the generation of static electricity and dust particles to fly around.

That is why onsite management of humidification and temperature conditions became vital for production plants of a multitude of industries. The most popular solutions are steam humidification and water-spray humidification systems.

Solution: Which adiabatic humidifier should you choose in a cleanroom?

There are many types of adiabatic humidifiers to choose from on the market. AKIMist® “E” stands out for its non-wetting capabilities. The droplets made with AKIMist are so small (below 10µm) that they will bounce back from the surface they touch without bursting. This gives AKIMist an advantage among other adiabatic humidifiers as a cleanroom facility will want to protect its expensive machinery and equipment from water damage. In addition, the non-wetting capabilities will also reduce the risk of mold and bacteria growth as these tend to thrive in wet areas.

AKIMist® “E” is also known for its energy efficiency. It only uses 1/5 the energy compared to a conventional steam humidifier and is one of the most energy efficient humidifiers among adiabatic humidifiers. In addition, the use of AKIMist will cool the air with approximately 2 degrees as an added benefit which futher saves costs on airconditioning and electricity.

Benefits of using the AKIMist® Dry Fog Humidifier

Energy and cost

AKIMist is extremely energy-efficient and uses up to 83% less energy than conventional humidification systems.

AKIMist cools around 2 degrees while controlling the humidity level. It reduces 20% of the energy used for air-conditioning and thereby saves cost.

AKIMist can be used for spot humidification and be placed directly by the source of issue. This reduces the price significantly as only a few units may be needed.

Installment and maintenance

AKIMist requires very little maintenance compared to other humidification equipment. In addition, it is very easy to maintain as it is installed within the factory and hanging from the ceiling or wall.

AKIMist is easy to install and can be fitted into any current HVAC design. AKIMist can be installed with a wall or ceiling fitting or

even as a portable option.

AKIMist is very compact. Like the size of a 5 inch smartphone. This makes it easy to fit into tight factory spaces.

Health and Environment

AKIMist can maintain an ideal humidification level with the help of a sensor. This significantly reduces the build-up of static electricity in a factory and reduces errors and scrap.

Due to the small size droplets, which are as small as dust particles, these droplets can suppress the dust. In addition, the increased humidity also helps to suppress dust.

Maintaining a relative humidity level of around 50% will reduce the risk of viruses from spreading between employees. This increases the well-being of the employees and increases productivity.

Learn more about the unique technology behind Dry Fog humidification

AKIMist® “E” Dry Fog Humidifier

Our AKIMist®“E” spreads a Dry Fog that humidifies indoor environments without wetting due to its tiny droplet size around 7.5 µm.

demo of AKIMist®

Experience AKIMist® Dry Fog technology in person at your facility our ours. It’s also possible to rent a portable unit for a testing period.

Related articles

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”