Pre-treatment process

Ikeuchi provides a number of solutions for the pre-treatment process in Automotive

Pre-treatment process

Cheap produced spray nozzles can lead to a number of issues during the pre-treatment process. Problems include everything from clogged nozzles, downtime maintenance, water wastage, car body defect etc.

Highlights

- Pre-treatment

- Water-rinsing

- Cleaning

- Degreasing

- Deposition prevention

Improve the PCB wetting process with spray nozzle technology

Pre-treatment

In automotive manufacturing, pre-treatment refers to the critical surface preparation process that occurs before painting or coating a vehicle’s metal components—primarily the car body (also known as the body-in-white). This process ensures strong adhesion of the paint and provides corrosion protection.

Ikeuchi provides spray nozzle solutions for the pre-treatment for painting, water rinsing process, cleaning etc. Our INVV and QB series nozzles are ideal for this process as they are easy to install, adjust and quickly detachable; “One touch” nozzles. This makes it possible to quickly switch between spray nozzles during the pre-treatment process.

Degreasing and washing

Degreasing and washing is a crucial step in automotive pre-treatment because it removes contaminants such as oils, waxes greases, and other residues—from the metal surfaces of vehicle parts before painting or coating. This step helps to prevent coating defects and improves paint adhesion.

For this process, we offer our VVEA series nozzles. VVEA is known for its semi-fine atomization with a mean droplet diameter of 20 µm ~ 400 µm. This leads to an improved washing capability with a significant reduction of demineralized water.

Deposition prevention

In automotive pre-treatment, preventing unwanted deposition is critical to ensure consistent coating quality, corrosion protection, and paint adhesion. Deposition refers to the buildup of contaminants, sludge, or residues on parts, equipment, or within the process tanks during pre-treatment.

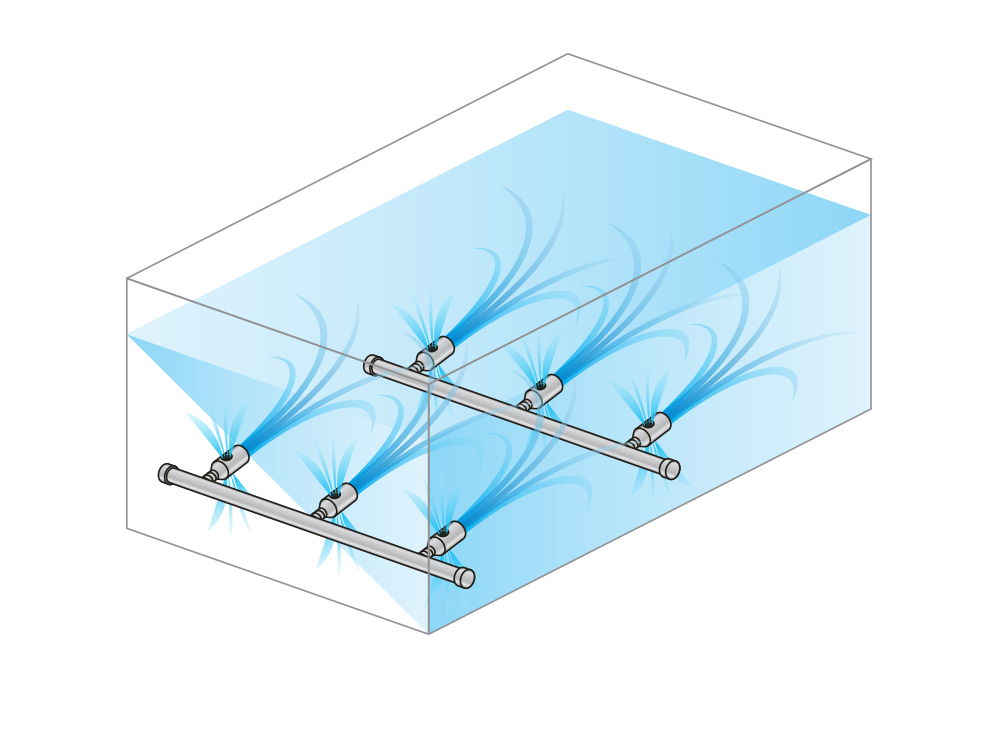

For this process, we offer our EJX series nozzles. The EJX is known for its simple, effective structure, and lightweight design. The EJX series nozzle ejects 3–4 times more volume than the amount originally supplied, making it ideal for cleaning in liquids.

- High chemical resistance

- High precision spraying

- High wear resistance

- Reduced water consumption

Related products

Case studies

Reduction of paint defects at a plastic bumper manufacturer

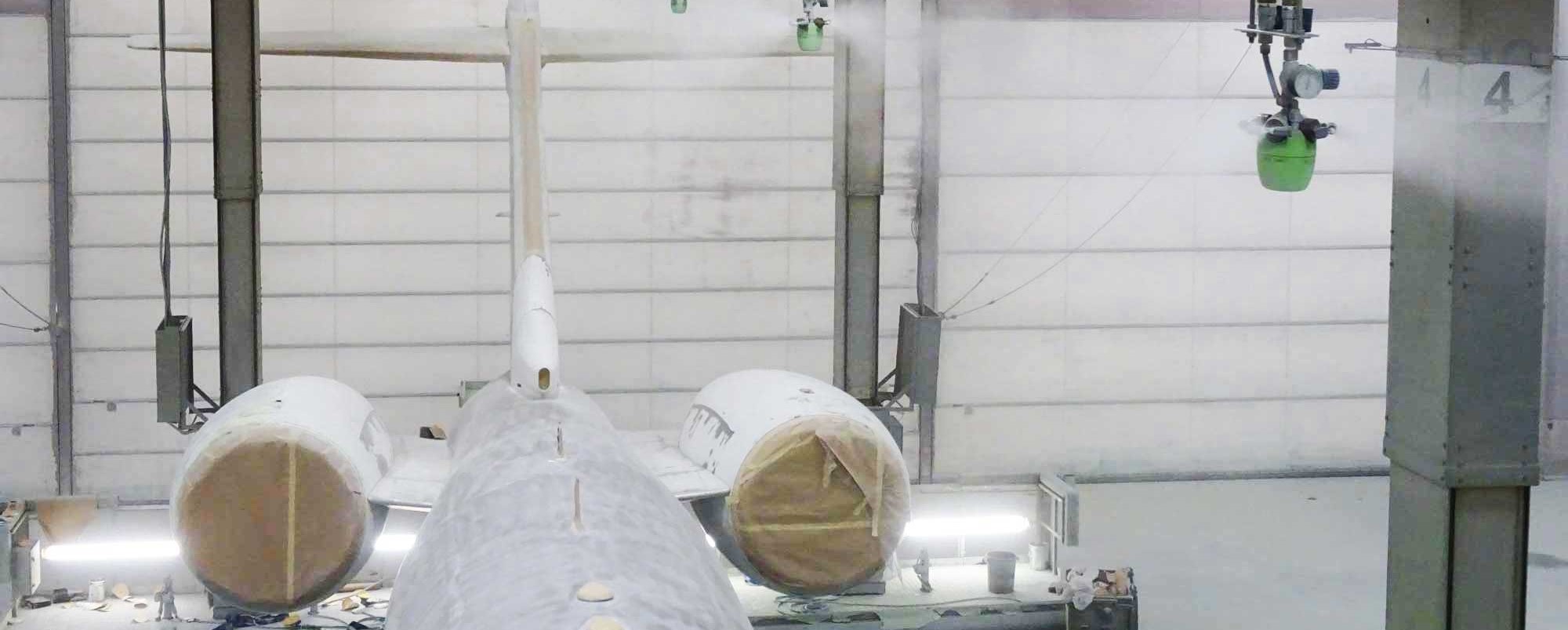

Dust particles suppression in MRO hangar

Customer stories: real experiences, genuine satisfaction

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

Experience the impact of Ikeuchi’s precision spray technology and innovative solutions through the voices of industries worldwide. See how we help businesses excel with custom-made solutions and unparalleled reliability.

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”