Cooling and thawing

Ikeuchi can provide a number of spray nozzle solutions for cooling and thawing

Cooling and Thawing with spray nozzle technology

To ensure the maintenance of raw and end-products quality, the processes of cooling and thawing (defrosting) are imperative food and beverage standards. Cooling is implemented to decrease a product’s temperature to assist its transition from one stage to another. Moreover, the temperature can also be maintained for other food and beverage processes (e.g. fermentation and beer processing).

Highlights

- Coooling

- Thawing

- Pasteurization

- Increased safety

- Increased hygiene

Cooling and Thawing solutions

Spray nozzle cooling

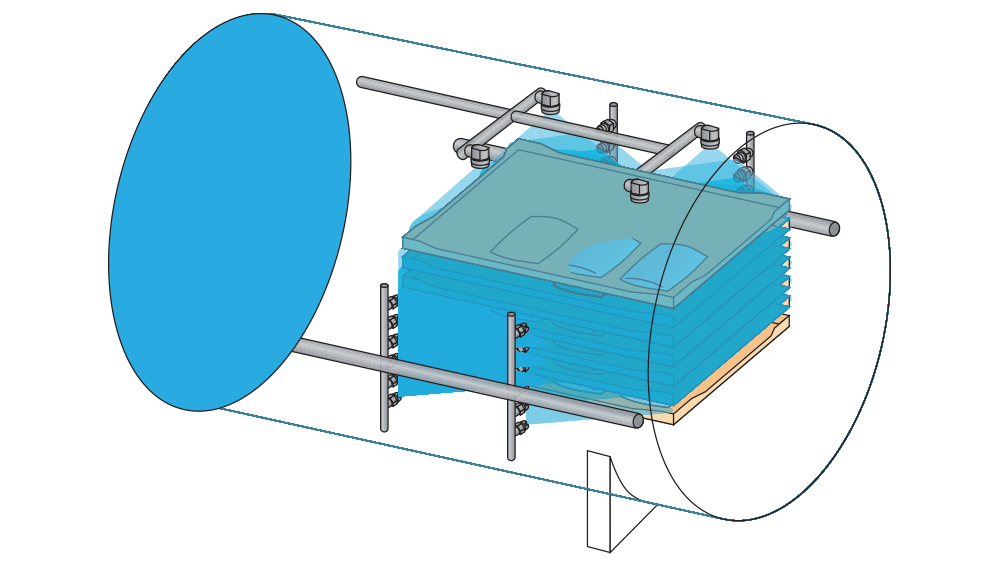

Cooling of food is a critical process in food safety and preservation. It is essential in order to maintain the quality and extend the shelf life. In addition, cooling food quickly to safe temperatures will slow down the growth of harmful bacteria and increase safety. Ikeuchi offers conical and fan-shaped spray nozzle to effectively cool food. For this application, we recommend our AJP nozzle.

Thawing with spray nozzles

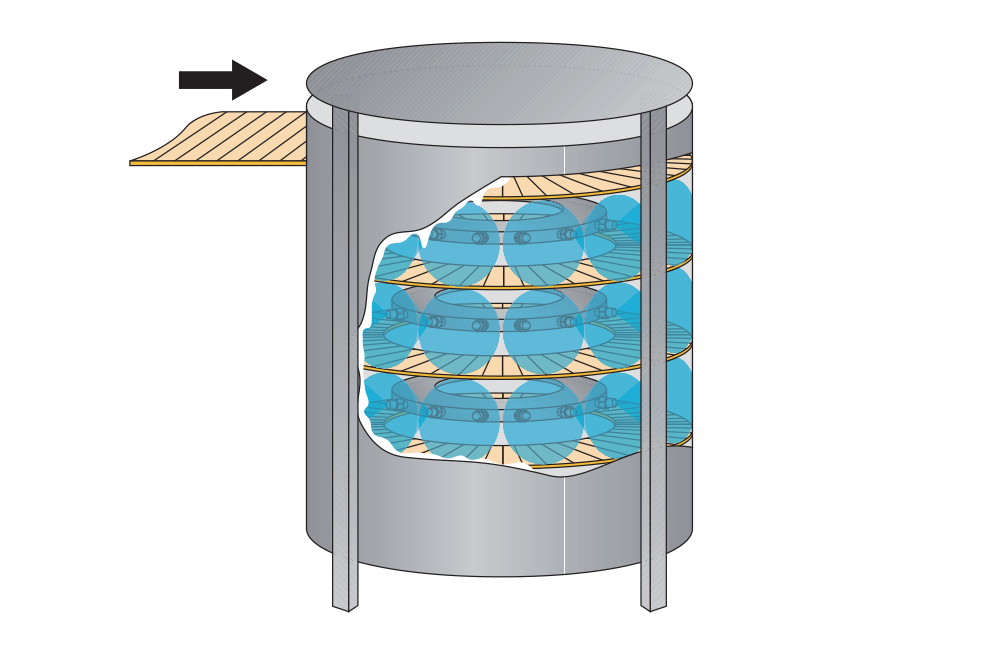

The process of thawing refers to the defrosting of a product (frozen food) to a temperature of slightly above 0° C. This state is where there’s no residual ice. Moreover, at this point the temperature plays a critical role not only for food safety reasons, but also for quality reasons. Freezing doesn’t kill bacteria; it only stops its growth.

However, through thawing, bacteria can reemerge and spread. This leads to bacteria causing spoilage, food poisoning, or contamination. Ikeuchi can provide a spray nozzle solution for defrosting or thawing through warm water with an even spray distribution. For this application, we recommend our JJXP or BBXP nozzles.

- Increase safety

- Increase product quality

- Increase productivity

- Increase hygiene

Related products

Case studies

Tank cleaning for miso paste production process

Disinfection of containers for coffee creamer

Spray disinfection in bread cooling rooms

Customer stories: real experiences, genuine satisfaction

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

Experience the impact of Ikeuchi’s precision spray technology and innovative solutions through the voices of industries worldwide. See how we help businesses excel with custom-made solutions and unparalleled reliability.

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”