Iron and steel making

Ikeuchi's spray nozzle solutions for the iron and steel industry

Ikeuchi has been developing spray nozzles for the iron and steel industry since 1983. Spray nozzles are applicable throughout the entire process of iron and steel making, and Ikeuchi helps steel and iron-makers to produce effective and cost-saving production lines. Our spray nozzle solutions include: Descaling, roll cooling, secondary cooling on CMM, flue-gas cooling, dust suppression, cooling and galvanizing, degreasing and rinsing, blow-off cooling with air nozzles.

CFD simulation for product optimization

Ikeuchi carries out CFD analysis to find the optimal product application and performance for our customers in projects for the iron and steel industry. CFD analysis is an excellent way to simulate and visualize product performance and to localize weak points in the design or spraying impact. Consequently, these can be optimized until the optimal result is reached. This saves our customers time and cost as experiments can be carried out in-house and prior to actual product testing.

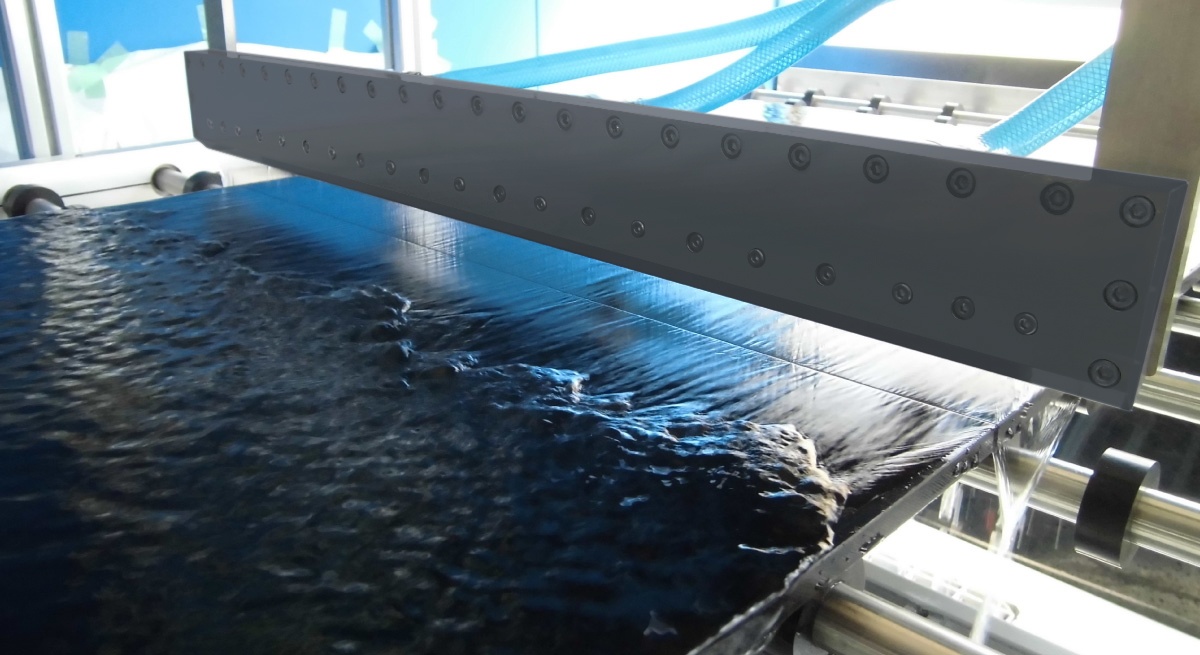

Spray cooling experiments

In our spray cooling experiments, we measure each aspect of the cooling performance from fog density and spray speed to droplet diameter, spray impact, air flow and spray area. When combining this knowledge with factors such as temperature, exhaust, time drainage, flown and blown air, the effects of cooling can be measured precisely.

Product applications for iron and steel:

Success stories

Energy saving dual spray nozzles in Continuous Casting Machine