Spray nozzles for the steel making process

Ikeuchi provides a number of solutions for the steel making industry

Spray nozzle solutions for the steel industry

With the increasing regulations for emissions control in iron and steel making, it has become necessary to implement new solutions in all parts of the process chain. Ikeuchi offers a number of solutions in steel manufacturing from secondary cooling on CCM to gas cooling and dust suppression.

Highlights

- Secondary cooling

- Flue-gas cooling

- High precision spraying

- Dust suppression

- High wear resistance

Improve the steel making process with precision spraying

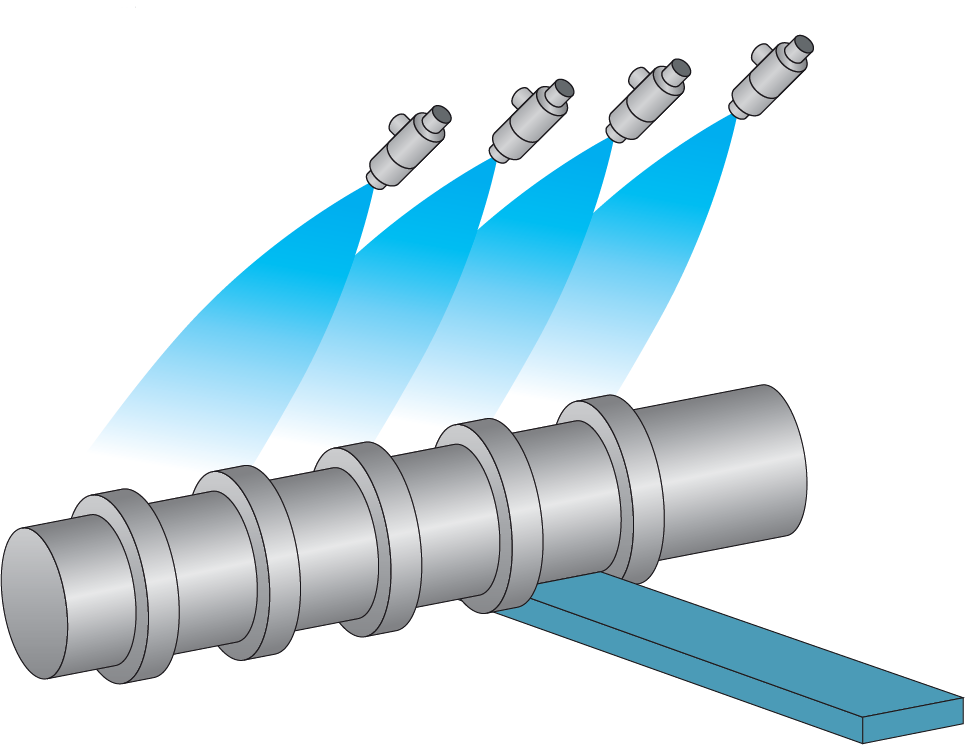

Secondary cooling on CCM

For the secondary cooling process on the CCM, a strong impact force is needed to break through the boiling surface. To cool down the steel slabs, it requires an even (uniform) spray distribution with as high impact as possible to ensure a smooth surface texture. Ikeuchi offers DOVEA pneumatic spray nozzle. It can generate a large range of spray capacity without changing the spray angle.

By controlling the spray angle and distribution, it is possible to produce different types of steel on the same CCM without changing the nozzle. Just adapt the spray capacity to the steel’s characteristics. This allows to reduce maintenance time and stock arrangements. DOVEA has a unique design with a less clogging structure. This ensures a uniform cooling performance and an increased lifetime value, compared to conventional models.

We also provide a dual nozzle solution (hydraulic + air with check valve) for higher energy efficiency. Check out our dual solutions below: VVP+AS and DDRP+AS

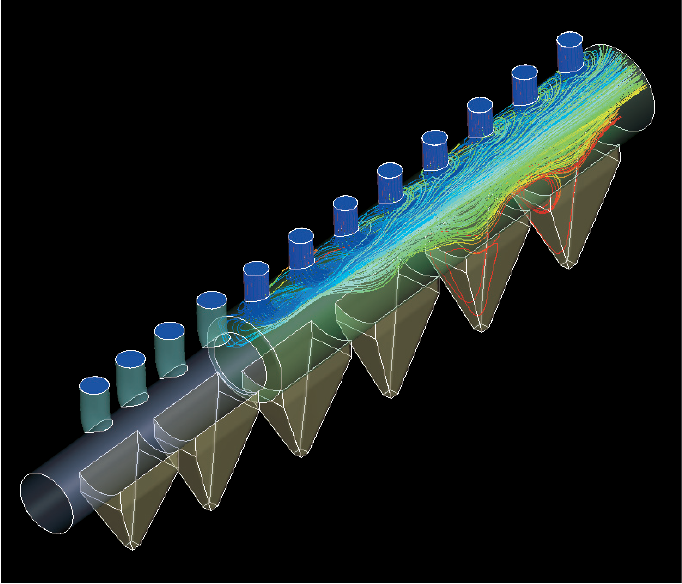

Flue-gas cooling

Cooling of high temperature flue gas, such as sintering exhaust, requires spray control and droplet diameters that enable complete evaporation. Ikeuchi uses CFD simulation when selecting the nozzles and the control system to ensure the complete evaporation of the water sprayed from our cooling nozzles.

We can perform a variety of measurements and simulations to assist you in choosing the correct nozzle. Ikeuchi’s GSIM II series can be used for flue-gas cooling. It is a pneumatic spray nozzle with a fine-fog spray of 50µm.

Dust suppression

Dust suppression is a crucial aspect of environmental management in steel production. The processes involved in steel manufacturing generate significant amounts of dust and particles, which can have adverse effects on air quality, worker health, and production equipment. Ikeuchi offers several types of spray nozzles equipment to suppress dust. Our GSIM II series can be used for dust suppression around exit of rolling mill to prevent particle contamination on the end-product.

- High chemical resistance

- High precision spraying

- High wear resistance

- Pollution control

Related products

Case studies

Energy saving dual spray nozzles in Continuous Casting Machine

Customer stories: real experiences, genuine satisfaction

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

Experience the impact of Ikeuchi’s precision spray technology and innovative solutions through the voices of industries worldwide. See how we help businesses excel with custom-made solutions and unparalleled reliability.

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”