Surface finish in steel industry

Ikeuchi provides a number of solutions for steel making industry

Surface finish solutions

Surface finish is the process of achieving the desired surface of the steel and involves several processes depending on the end usage. Ikeuchi offers several spray nozzle solutions which support the surface finish.

Highlights

- Cooling after galvanizing

- Degreasing and rinsing

- High precision spraying

- TAIFUJet®

- BRASIKAN®

Enhanced surface finish solutions

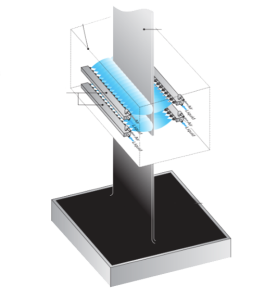

Cooling after galvanizing (CGL)

Cooling after galvanizing steel is a critical step to ensure the quality and performance of the galvanized coating. Our BIM series spray nozzles can be used to cool the top roll and steel sheet after galvanizing. The BIM nozzles can be integrated in a spray header to produce a uniform spray distribution across the entire spray area. It can spray on steel plates effectively and uniformly at high speed.

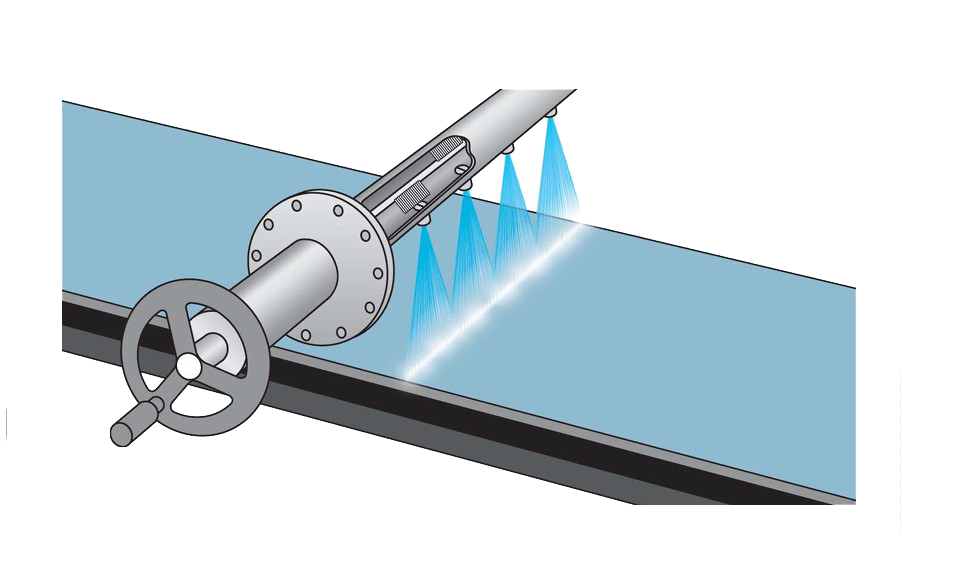

Degreasing and rinsing (CGL)

Degreasing and rinsing are essential steps in the surface preparation process for galvanizing steel. They ensure that the steel surface is clean and free of contaminants. Our BRASIKAN solution is an air-driven automatic brush cleaning nozzle which was especially developed for this process. Brasikan allows remote control of spray and cleaning mode. Therefore, it can be installed in a narrow, inaccessible place. With a timer. it can also be programmed to clean automatically.

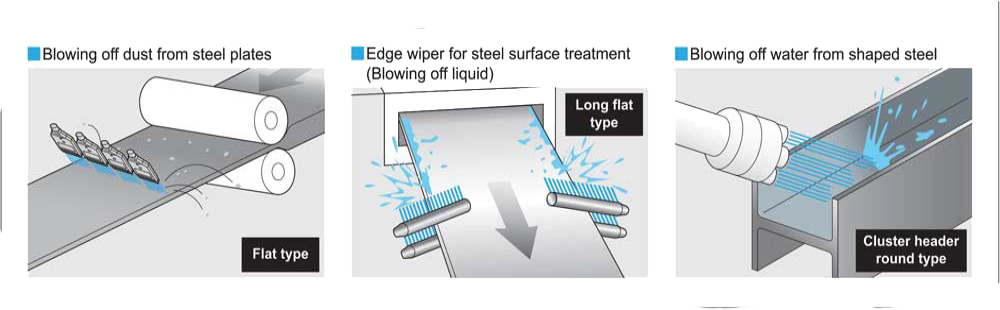

Blowing off with Air nozzles

Blowing off steel for drying and removing dust and liquid is an important step on the galvanizing line as well as on the coating line. Ikeuchi’s TAIFUJet series are ideal for this process due to their high impact and unform airflow. TAIFUJet is available in 3 different shapes; flat, long and round type. TAIFUJet air nozzles also provide 45% energy saving compared to conventional single hole air nozzles as well a significant noise reduction of 10db.

- Reduce cost

- Increase efficiency

- Reduce clogging

- Uniform spray distribution

Related products

Case studies

Energy saving dual spray nozzles in Continuous Casting Machine

Customer stories: real experiences, genuine satisfaction

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

Experience the impact of Ikeuchi’s precision spray technology and innovative solutions through the voices of industries worldwide. See how we help businesses excel with custom-made solutions and unparalleled reliability.

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”