Drying process

Ikeuchi provides a number of solutions for the drying process in the paper and pulp industry

Paper drying process

The drying process in paper making is an important stage in the production of paper. The drying process reduces the moisture content of the paper web after it has been formed and pressed. The drying process also ensures that the paper attains the desired physical properties and quality for its intended use.

Highlights

- Paper drying

- Polishing process

- Size press

- Dryer canvas

- High wear resistance

Enhance the paper drying process with wear resistant spraying equipment

Lubricant spraying

During the drying process, lubricant spraying is important in order to keep the sheet moving smoothly and protect the equipment. It is important that the lubricant spraying consist of fine atomization to avoid wetting the sheet. For this application, we recommend our fine atomization BIM two-fluid nozzle. The BIM nozzle has a droplet size 100 µm or less.

Size-press

After the pre-drying section, the paper is transferred in the size press where nozzles are spraying starch onto the wet web of paper. This process is required to enhance the binding of the paper fibers, making it stronger and durable. The nozzles that can assist with the spraying of starch are our AP and VP-series.

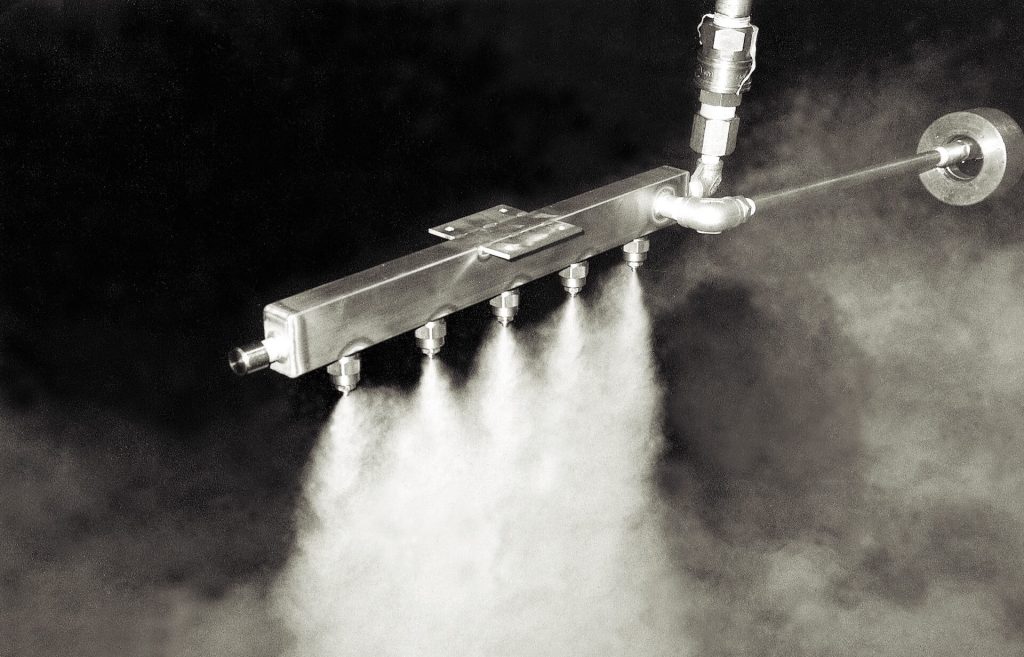

Dryer-canvas

After the size-press, the paper is transferred to the dryer canvas. Its primary function is to support the paper web as it passes through the drying cylinders, ensuring efficient and even drying while maintaining the quality and integrity of the paper. Within this section a series of nozzles is requested to be installed to ensure that the dryer canvas is kept clean. The BIM header nozzles are suitable for this type of operation, as they provide a uniform distribution. Moreover, the volume of spray can be controlled, which assist in reducing the amount of utilized spray. The paper is then transported to the drying section.

Cooling soft calendar roll

At the end of the drying process, it is important to cool the soft calendar roll in order to prevent blackening, cracking or curling. If the paper is too hot when passing through the nip, high compression can lead to an effect known as “calender blackening.” This is where the paper becomes too dense and develops small, translucent, dark spots that ruin the aesthetic and reduce print quality. For this process, we recommend our TAIFUJet® air nozzles.

- High chemical resistance

- High precision spraying

- High wear resistance

- Reduced water consumption

Related products

Case studies

Customer stories: real experiences, genuine satisfaction

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

Experience the impact of Ikeuchi’s precision spray technology and innovative solutions through the voices of industries worldwide. See how we help businesses excel with custom-made solutions and unparalleled reliability.

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”