Finishing and winding

Ikeuchi provides a number of solutions for finishing and winding process

Spray nozzle solutions for the finishing and winding process

The finishing and winding process in paper making are the final stages that prepare the paper for shipment to customers. These processes ensure the paper meets specific quality standards and is in the desired format for further use.

Highlights

- Paper cooling

- Humidity

- Moisture

- Pipe cleaning

- Air nozzles

Enhance the paper finishing process with cooling and moisturization technology

Cooling of paper in after-drying process

In the after-drying section, the web of paper passes through heated calendar rolls that smoothen and compress the paper. In this section 2 types of nozzles are required. One type of nozzles to softly cool the paper. For this the TAIFUJet ® series air nozzles are optimal. The second type of nozzles are the BIM series which assist with moistening the web of paper.

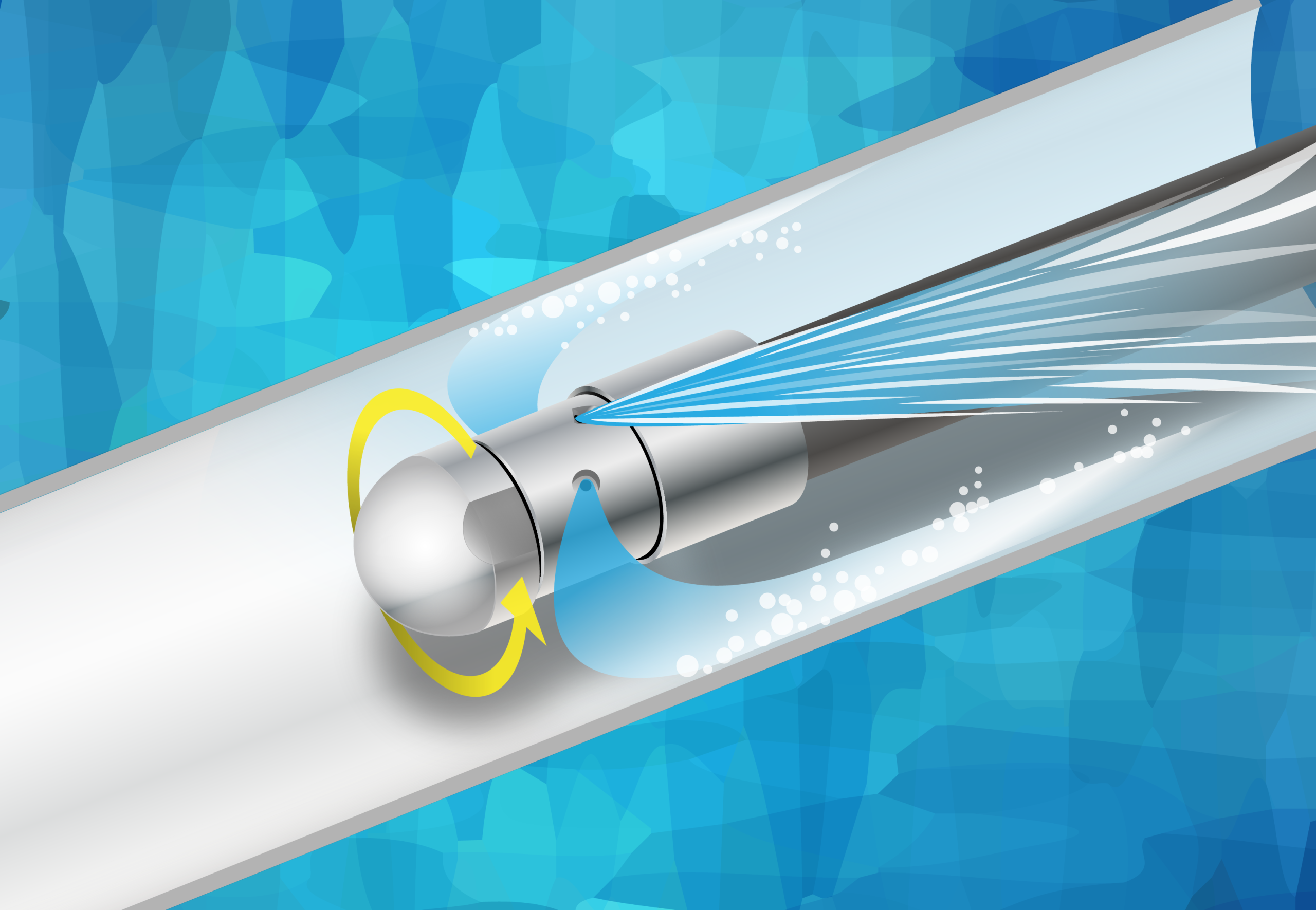

Pipe-cleaning nozzle

During the paper cooling process, it must be ensures that showered water does not contain recipients that might affect the paper. In order to prevent this, a pipe cleaning spray nozzle should be implemented. In this case, the RSP series is the optimal self-driven pipe cleaning nozzle.

Humidity and moisture

Moisture and humidity are important aspects within a paper and pulp mill, especially in the finishing and winding process. If the relative humidification level is not at the recommended percentage for the paper fabrication, it will not only affect the paper machines through ESD, but also it is detrimental to the reel or web of paper. The AKIMist®“E” Dry Fog Humidifier is the cost-effective solution to these challenges. Through its implementation it not only solves these issues and challenges but provides more benefits:

- “Dry Fog” is a fine mist that does not wet the wall, the floor, the machines, or the surrounding environment

- Reduction of sticking and inclusion of paper dust

- Suppression of airborne paper dust

- In large room or small space, AKIMist®“E” can raise up humidity stably and quickly. Ideal for static electricity control, paper-dust suppression and moisture control in rewinding, slitting packaging process, etc.

- Assists in establishing an ideal level of relative humidity, not too dry or too moisty, that assists in reducing the probability of the paper to curl and tear.

- Humidity control

- Pipe cleaning

- High wear resistance

- Reduced water consumption

Related products

AKIMist® “E” Dry Fog Humidifier

AKIMist® is unique for its non-wetting ability due to the extremely tiny droplet size around 7.5 µm – making it ideal for sensitive environments. The tiny droplets can also suppress dust, making it an ideal combination for a pulp and paper production.

Case studies

Customer stories: real experiences, genuine satisfaction

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

Experience the impact of Ikeuchi’s precision spray technology and innovative solutions through the voices of industries worldwide. See how we help businesses excel with custom-made solutions and unparalleled reliability.

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”