NOx reduction with spray nozzle technology

Ikeuchi can provide a number of spray nozzle solutions for NOx reduction

NOx control

Industrial factories are legally required to control pollution, particularly nitrogen oxide (NOx) emissions, under regulations such as EU Directive VII. As a result, the use of spray nozzles or injection lances for NOx reduction is a common practice in pollution control systems, supporting catalytic reduction processes that help purify exhaust air.

The performance of these spray nozzles is critical, as it directly influences the efficiency of NOx reduction. However, environmental factors such as high temperatures, clogging, and external wear can compromise nozzle performance over time, leading to increased maintenance costs and the need for frequent replacements.

Highlights

- Air pollution

- NOx reduction

- Injection lances

- SNCR

- SNC

NOx reduction solutions

Selective Non-Catalytic Reduction

Selective Non-Catalytic Reduction (SNCR) is a process used to reduce nitrogen oxide (NOx) emissions from combustion sources such as boilers, furnaces, and waste incinerators. It requires a narrow range of temperatures for effective NOx reduction and it is not suitable for large-scale NOx reduction. For this application we suggest to use our DOVVA-G-series. This is a flat Spray Pneumatic Spray Nozzle for SNCR with semi-fine atomization to optimize the reaction with ammonia water. It produces a mean droplet diameter of 80 μm or more (*3) and spray at an angle of 70° or 55°.

Selective Catalytic Reduction

Selective Catalytic Reduction (SCR) is a highly effective method for reducing nitrogen oxide (NOx) emissions from combustion processes and it is the most common. SCR is more expensive than SNCR due to the catalyst specifications but makes up for it in terms of efficiency.For this application we recommend our SETO-jet series. It is a Clog-resistant Fine Fog Nozzle developed for for SCR to reach full evaporation with smaller droplets. The mean droplet diameter is 60 µm or less (*3).

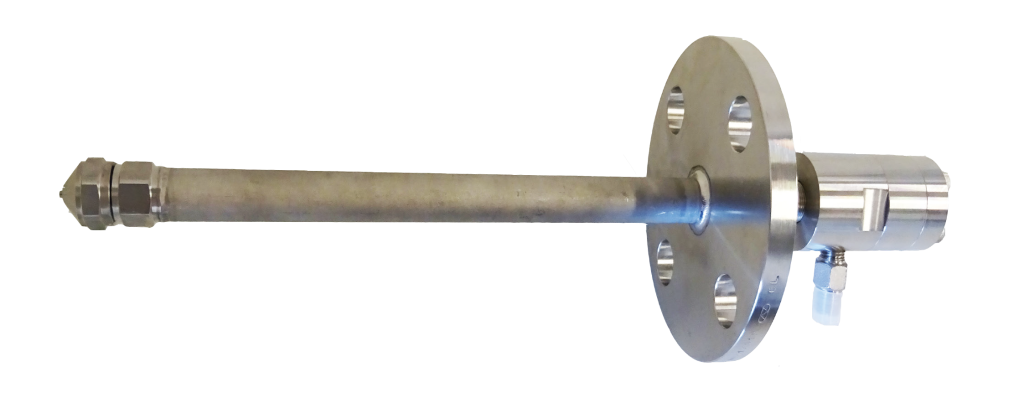

Protective equipment

In order to control “air contamination” worldwide, our R&D department has developed equipment to protect your injection lance. We can offer a protective air tube, Water-cooling jacket, and Retracting mount equipment.

- Pollution control

- Wear resistance

- Increase productivity

- Clog resistance

Related products

Case studies

Conveyor belt sorting system with air nozzles

Tank cleaning for miso paste production process

Customer stories: real experiences, genuine satisfaction

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

Experience the impact of Ikeuchi’s precision spray technology and innovative solutions through the voices of industries worldwide. See how we help businesses excel with custom-made solutions and unparalleled reliability.

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”