SOx reduction with spray nozzle technology

Ikeuchi can provide a number of spray nozzle solutions for SOx reduction

SOx control

Desulfurization plants must meet strict industrial standards to treat exhaust gases before releasing them into the environment. Effective SOx reduction relies on the atomization of limestone slurry into fine droplets.

However, the abrasive nature of the slurry poses a challenge. It causes internal wear on the nozzle, significantly shortening its lifespan. Achieving smaller droplet sizes requires increased rotational force inside the nozzle, which intensifies the impact of the slurry against the nozzle walls—accelerating internal abrasion and further reducing durability.

Ikeuchi has developed a number of spray nozzles which can solve these common issues.

Highlights

- SOx control

- Wet FGD

- Semi-dry FGD

- Anti-clog

- High wear resistance

SOx reduction solutions

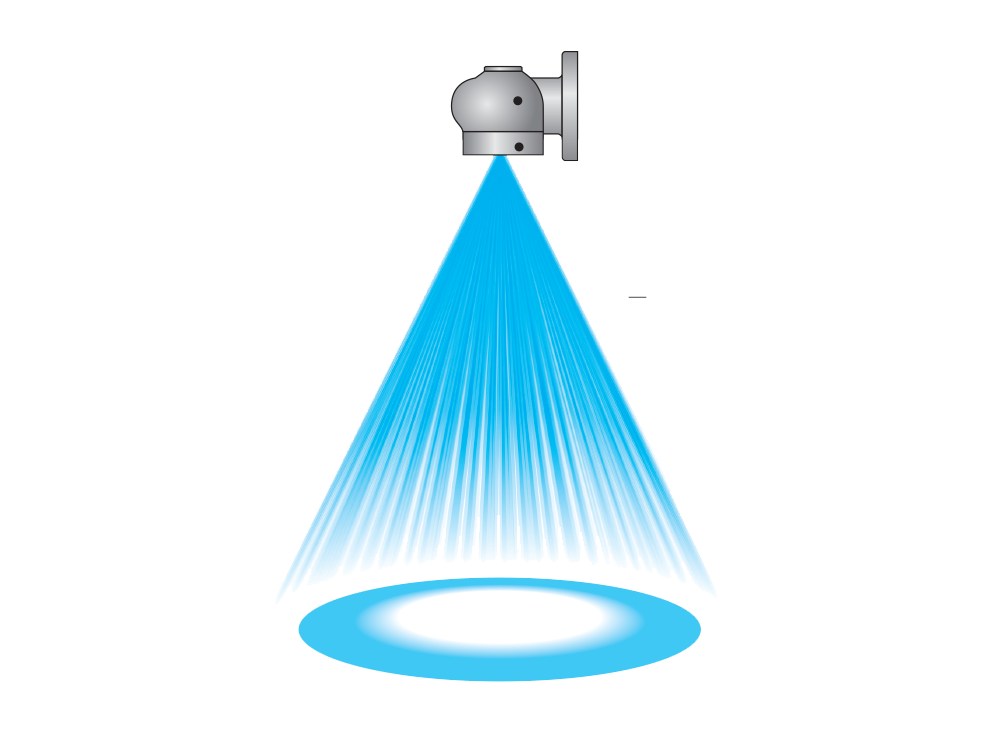

Wet FGD

In order to improve the longetivity of the spray nozzle used for wet FGD, IKEUCHI recommends SiC and SiSiC material for this process. The large free passage diameter of the nozzles, of about 2.2 – 2.8 times larger than X shape whirler full cone nozzles, minimizes the clogging and creates smaller droplets.

Advantages of the solution

- Highly wear-resistant as made all in SiC (or SiSiC)

- Lightweight, 1/3 weight compared with stainless steel nozzles

- Large free passage diameter for minimal clogging

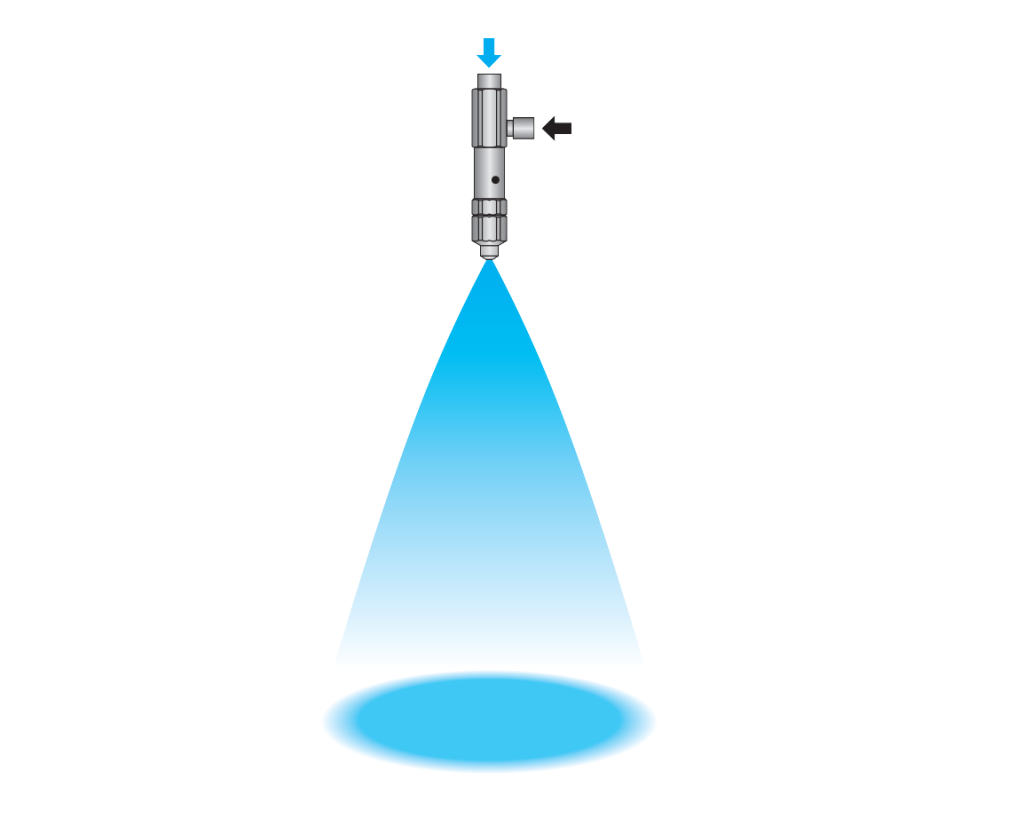

Semi-dry FGD

For Semi Dry FGD, IKEUCHI recommends spray nozzles with a smaller droplet size and a strong wear resistance to heat by using Alumina tip (AL99). Alumina is known for its high wear resistance and can last 20-30 times longer than stainless steel spray nozzles.

Advantages of the solution

- Simpler equipment layout

- Less maintenance = time savings

- No wear, no corrosion during 5 years operation

- Pollution control

- Wear resistance

- Increase productivity

- Clog resistance

Related products

Case studies

Conveyor belt sorting system with air nozzles

Tank cleaning for miso paste production process

Customer stories: real experiences, genuine satisfaction

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

Experience the impact of Ikeuchi’s precision spray technology and innovative solutions through the voices of industries worldwide. See how we help businesses excel with custom-made solutions and unparalleled reliability.

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”