AirAKI® Dry Fog industrial humidification system

AirAKI® is an Industrial Humidification System utilizing several AKIMist® humidifiers combined with a complete ROI system and sensors.

What is AirAKI®?

AirAKI® is an industrial humidification system that controls and optimizes humidity levels in a factory utilizing non-wetting “Dry fog”. Dry fog is non-wetting due to its tiny droplet size. AirAKI is commonly used by manufacturers as a means to reduce static electricity and reduce the negative effects related to this. AirAKI is extremely energy-efficient and by switching from steam humidification to AirAKI you can reduce energy costs by 80%, and return the investment in less than two years.

Highlights

- Reduce static electricity

- Non-wetting

- Return investment in 1.5 y

- Dust suppression

"After installing the AirAKI® dry fog humidification system at our production facilities, we solved a long-term problem with air-humidity. We now have a stable humidity level at 46 – 54% thanks to AirAKI. I can highly recommend it to all potential applicants."

Ing. Jozef Bendík, ChemosvitHow is AirAKI® installed?

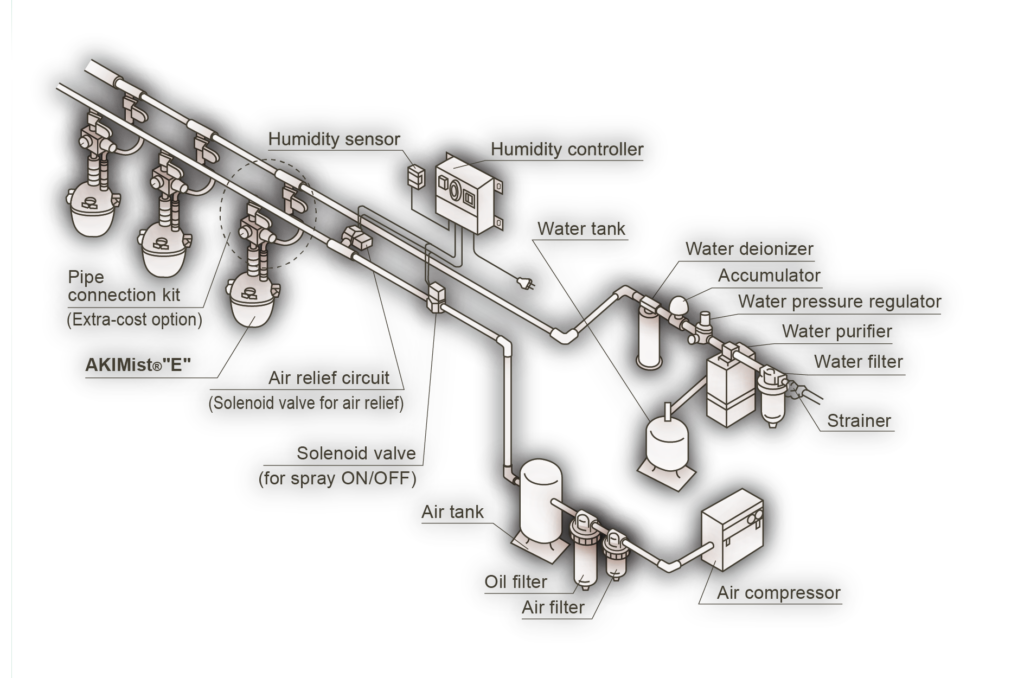

As can be seen below, AirAKI includes several units of AKIMist humidifiers, depending on the size of the building and humidity targets. In addition, the system consist of a humidity sensor which will turn the system on a off depending on the humidity level. This reduces waste of unneccesary energy like we know it from steam based humidification systems. The system is also connected to compressed air as well as a ROI water system.

Applications of AirAKI

AirAKI® has been implemented in several industries including automotive, printing, pulp & paper, textile, EMS, SMT and food & beverage. Besides from suppressing static electricity, AirAKI also has the added benefit of suppressing dust. The tiny droplets produced are ideal for capturing dust particles due to their large total surface area.

Applications

Dry fog humidification can be used for a number of applications:

- Humidification control

- Elimination of static electricity

- Dust suppression

- Reduce virus spread

- Disinfection

Other benefits of using the AKIMist® Dry Fog Humidifier

Energy and cost

AKIMist is extremely energy-efficient and uses up to 80% less energy than conventional humidification systems.

AKIMist cools around 2 degrees while controlling the humidity level. It reduces 20% of the energy used for air-conditioning and thereby saves cost.

AKIMist can be used for spot humidification and be placed directly by the source of issue. This reduces the price significantly as only a few units may be needed.

Installment and maintenance

AKIMist requires very little maintenance compared to other humidification equipment. In addition, it is very easy to maintain as it is installed within the factory and hanging from the ceiling or wall.

AKIMist is easy to install and can be fitted into any current HVAC design. AKIMist can be installed with a wall or ceiling fitting or

even as a portable option.

AKIMist is very compact. Like the size of a 5 inch smartphone. This makes it easy to fit into tight factory spaces.

Health and Environment

AKIMist can maintain an ideal humidification level with the help of a sensor. This significantly reduces the build-up of static electricity in a factory and reduces errors and scrap.

Due to the small size droplets, which are as small as dust particles, these droplets can suppress the dust. In addition, the increased humidity also helps to suppress dust.

Maintaining a relative humidity level of around 50% will reduce the risk of viruses from spreading between employees. This increases the well-being of the employees and increases productivity.

demo of AKIMist®

Experience the impact of Ikeuchi’s precision spray technology and innovative solutions through the voices of industries worldwide. See how we help businesses excel with custom-made solutions and unparalleled reliability.

Industries in which AKIMist® is used

From automotive to textile, Ikeuchi’s precision technology powers diverse industries worldwide. Our high-quality spray nozzles and humidification systems are designed to optimize processes, improve productivity, and reduce waste. With custom solutions for every sector, we help businesses achieve greater efficiency and sustainability.

Case studies

Conveyor belt sorting system with air nozzles

Tank cleaning for miso paste production process

Customer stories: real experiences, genuine satisfaction

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

Experience the impact of Ikeuchi’s precision spray technology and innovative solutions through the voices of industries worldwide. See how we help businesses excel with custom-made solutions and unparalleled reliability.

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”