Atomization spray nozzles

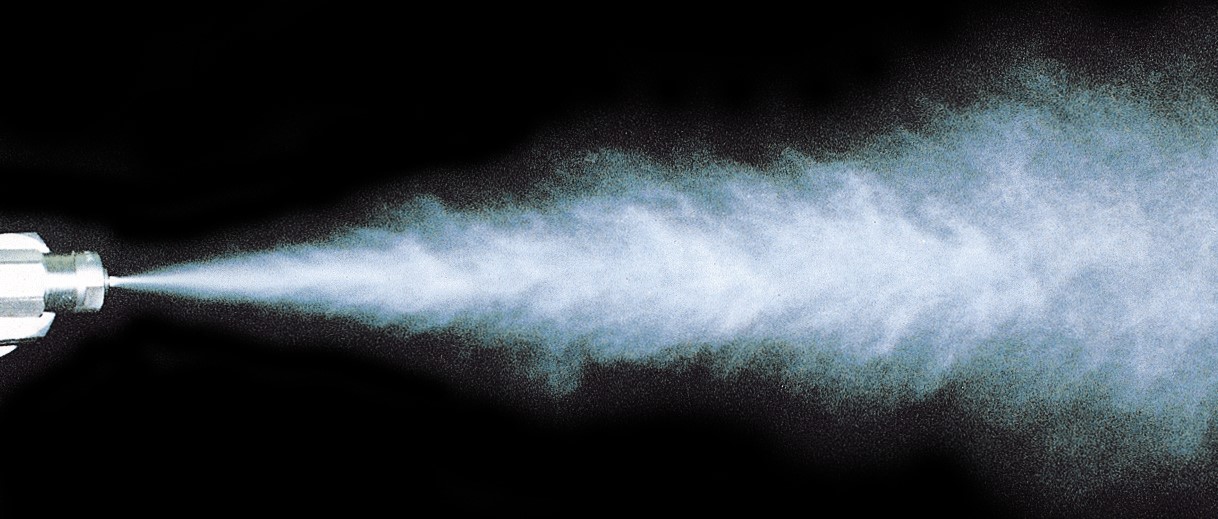

Atomization is the process of breaking a liquid into tiny droplets or particles.

The methods of atomization can be divided into:

- Hydraulic atomization

- Pneumatic atomization

- “AKIMist®” atomization

Hydraulic atomization

Hydraulic atomization consist only of water supply. The liquid is pushed though a tiny orifice at high pressure.

In the case of hydraulic atomization, the spray output will often vary between larger and smaller droplets due to the lack of compressed air. It is not possible to spray a fine mist with this method. The sprayed amount will also be limited due to the very small orifice. This method can be used in cases where a small consistent droplet size is unimportant, for instance in rinsing or cleaning. The technique requires high maintenance due to the pressure on the small orifice.

Pneumatic atomization

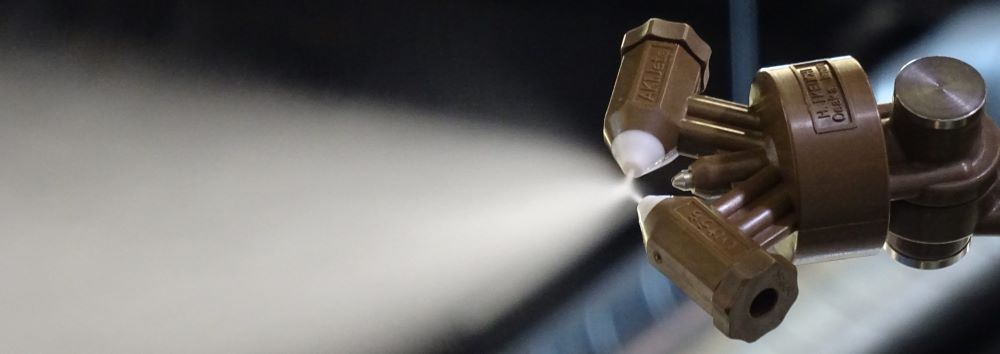

Pneumatic atomization consist of water and compressed air supply.

In the case of pneumatic atomization, it is more efficient than hydraulic atomization and it is possible to produce smaller droplets which sometimes evaporate. However, pneumatic atomization has its limitations in regards to producing a consistent size of tiny droplets (below 10µm) and it is an inefficient and energy-consuming way to obtain this.

AKIMist® atomization

The atomization technology which was invented for AKIMist®, combines water supply, compressed air and ultrasonic waves. Liquid is sent into the two spray orifices of the nozzle tip and is then atomized inside the orifices by shearing force as they collide. Shear force is the frictional force between the two liquids as they move at different speeds. The sheared liquid is then further re-atomized by 33,000–40,000 Hz ultrasonic waves. This way, an ultra-fine “dry fog” is created with a uniform spray droplets distribution.

Non-wetting

These droplets are so small (around 7.5µm) that they will bounce back from the surface they touch without bursting. This makes AKIMist® atomization the preferred choice among many production facilities to protect machinery and equipment from water damage.

Other benefits of using the AKIMist® Dry Fog Humidifier

Energy and cost

AKIMist is extremely energy-efficient and uses up to 83% less energy than conventional humidification systems.

AKIMist cools around 2 degrees while controlling the humidity level. It reduces 20% of the energy used for air-conditioning and thereby saves cost.

AKIMist can be used for spot humidification and be placed directly by the source of issue. This reduces the price significantly as only a few units may be needed.

Installment and maintenance

AKIMist requires very little maintenance compared to other humidification equipment. In addition, it is very easy to maintain as it is installed within the factory and hanging from the ceiling or wall.

AKIMist is easy to install and can be fitted into any current HVAC design. AKIMist can be installed with a wall or ceiling fitting or

even as a portable option.

AKIMist is very compact. Like the size of a 5 inch smartphone. This makes it easy to fit into tight factory spaces.

Health and Environment

AKIMist can maintain an ideal humidification level with the help of a sensor. This significantly reduces the build-up of static electricity in a factory and reduces errors and scrap.

Due to the small size droplets, which are as small as dust particles, these droplets can suppress the dust. In addition, the increased humidity also helps to suppress dust.

Maintaining a relative humidity level of around 50% will reduce the risk of viruses from spreading between employees. This increases the well-being of the employees and increases productivity.

Looking for atomization spray nozzles?

Related articles

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”