Save energy and costs on compressed air consumption

The vast majority of industrial companies use compressed air for applications like surface drying or cleaning. Compressed air is a form of energy storage due to its ability to perform when the air is decompressed. The production of compressed air is mostly generated by electrical energy through a compressor.

Due to the large amount of electrical energy necessary to produce compressed air, it is important to study how to reduce its energy consumption and thereby costs.

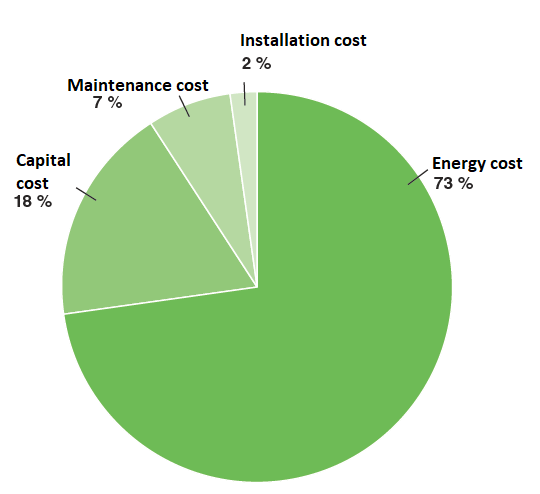

Where is the energy consumption allocated when producing compressed air?

In the industry, more than 10% of the electricity consumed goes to the production of compressed air. This varies according to the sector, as in some cases it can even reach up to 30% of the electrical energy used.

73% of the operating costs of a compressed air system comes from the electricity costs. The rest of costs include the initial investment, maintenance and costs of installation.

Since only 8-10% becomes useful energy capable of performing, the energy efficiency of a compressed air installation is very low. The remaining 92-90% are losses in compression, regulation, cooling, dehumidification, and leakage in equipment and pipelines.

In addition to the compressed air generated by the compression units, it is estimated that 50% is used in non-productive components such as leaks and inappropriate uses of compressed air.

How to reduce the operating costs of a system?

There are several measures that can be taken when it comes to saving on operating costs. An installation can be divided into two fundamental parts.

- The production, which includes compressors and air treatment.

- The demand, which includes distribution, storage systems and end-use equipment.

Proper coordination of production and demand leads to a reduction in costs.

There are several ways to make a more efficient installation and lower operating costs.

Cost and energy saving opportunities in a compressed air installation

Air leaks in a facility can lead to increased energy consumption, compromised air quality, and potential damage to equipment. The best way to avoid them is to practice frequent maintenance. It is considered “an installation in good condition” when the leaks imply maximum 10% of the production.

Because the compression process produces heat, it can be extracted by a cooling circuit and reused for other process. Energy recovery systems capture this waste heat and transfer it to a medium like water or air, which can then be used for purposes such as heating up the factory.

We recommend that the sucked in air is clean and cold in order to improve the performance of the compressor. Since the air increases in specific volume with the temperature, the colder it is, the more air will fit in the compressor. This will improve its performance.

There are sometimes parts of the installation which are obsolete. If these are removed, it could increase the efficiency. This is often the case with air nozzles. Instead of using a tube, we recommend to use nozzles designed for each application. We make the system more efficient by reducing its costs.

Why use IKEUCHI air nozzles

The IKEUCHI technical air nozzles have been developed to maximize the blowing efficiency. The wide range of models within each series offers the possibility of choosing the most suitable nozzle for each application, optimizing the blowing force and the air flow required. This integral design entails a reduction of costs in compressed air and a control of the blowing precision of each application.

When we blow with a free exhaust pipe, the distribution of the blowing force is irregular and the flow is turbulent. This results in inefficient blowing. This inefficient pulverization supposes an irregular blown diminishing the quality of each application.

The graph below shows the difference in the distribution of the blowing force between an open blue graphic tube and a nozzle of the gray graphic TF-R series.

Advantages of Ikeuchi air nozzles

In addition, another great advantage of the use of IKEUCHI technical air nozzles is that they have a lower consumption of compressed air flow compared to a free exhaust pipe. This reduces the operating costs of the installation.

The IKEUCHI model TF-R series nozzles are capable of reducing the flow of compressed air to between 79% and 91%.

Advantages:

- Reduction in compressed air consumption

- Uniform flow distribution

- Improving the efficiency of the application

- Reduced costs while increasing productivity

Do you also want to save costs on compressed air consumption?

Related articles

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”