Assembly process

Prevent ESD, reduce mounting defects, and minimize dust adhesion with precise Dry Fog humidity control

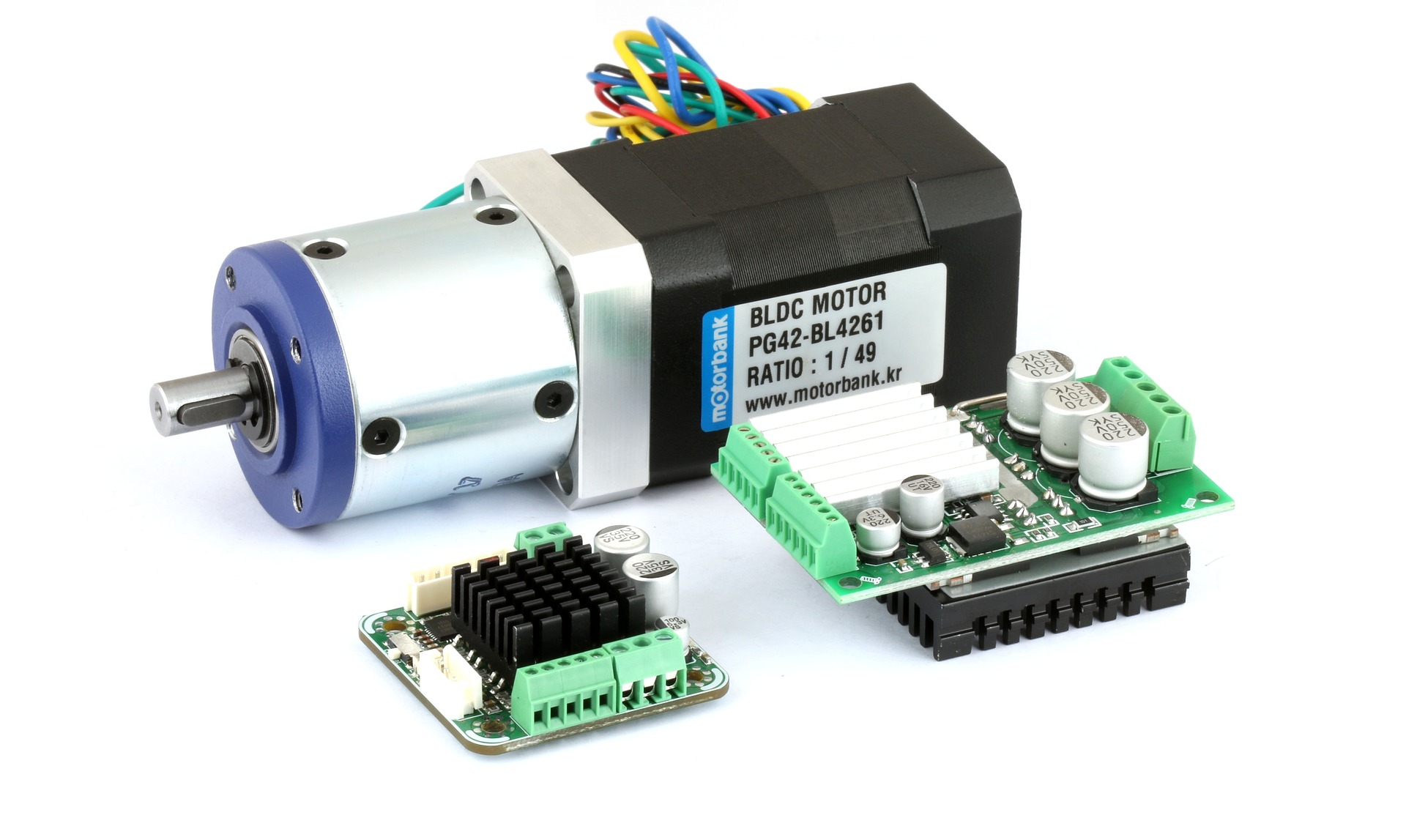

SMT assembly process

An insufficient humidity level during the SMT assembly process can cause issues such as static electricity (ESD) and dust adhesion, leading to problems like soldering defects, circuit damage, and improper mounting.

Highlights

- ESD prevention

- Dust prevention

- Error reduction

- Increased safety

- Cost reduction

ESD prevention with humidity control

Humidity control in SMT facility

By thoroughly analyzing the facility’s existing conditions—such as room size, air exchange rate, SMT line layout, and local climate—we provide a tailored installation solution to prevent ESD (electrostatic discharge) issues and minimize defect rates. Effective humidity control significantly reduces mounting defects and prevents dust adhesion. Additionally, the AKIMist® system offers a cooling effect of approximately 2°C, contributing to substantial savings in air conditioning costs.

By switching from your current steam humidification system to an adiabatic system, such as AKIMist®, you can save more than €60K per year in energy costs. This makes it possible to earn back your sustainable investment in just 2 years.

- Reduce defects

- Increase product quality

- Increase productivity

- Increase worker safety

Related products

AKIMist® “E” Dry Fog Humidifier

AKIMist® is unique for its non-wetting ability due to the extremely tiny droplet size around 7.5 µm – making it ideal for sensitive environments.

Case studies

Customer stories: real experiences, genuine satisfaction

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

Experience the impact of Ikeuchi’s precision spray technology and innovative solutions through the voices of industries worldwide. See how we help businesses excel with custom-made solutions and unparalleled reliability.

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”