Benefits of Dry Fog in specific industries

The AKIMist® Dry Fog humidification system has many benefits and are used in various factories such as electronics, printing, paper & pulp, plastic, chemical plants, automotive, textile, agriculture, painting, etc.

Our systems help solving many of our customers issues related to electrostatic discharges, dust adhesion, low humidity level, and even worker’s health management in winter. In this article we will highlight the benefits of dry fog in different cases.

Examples of industries where the AKIMist ® Dry Fog humidification system has been successfully applied:

- Printing

- SMT

- Electronics

- Plastics

Printing industry

Finding a humidity control suitable for each type of printing press and process has a big impact on the production.

Common problems caused by static electricity

- Dust adhesion to plate making

- Poor sticking

- Paper dust adhesion to printed materials

- Poor paper feeding (two-sheet feeding)

- Folding failure

- Ink scattering

- Paper jam

- Ignition of solvent

- Paper misalignment

- Responsiveness of high-speed machine

Common issues caused by insufficient humidity

- Paper break

- Curl due to expansion and contraction of paper

- Punching failure

- Paper joint failure

- Poor dimensional accuracy

- Poor registration

- Ink drying

- Ink stains

- Print wrinkles

- Ruled and back cracks

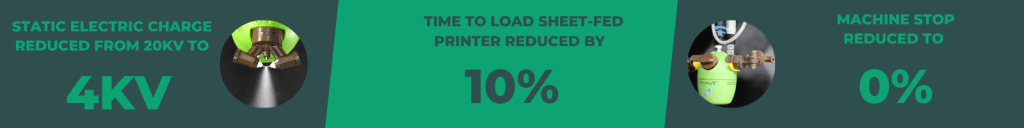

AKIMist®”E” benefits for Web Offset Printing Process

- AKIMist® has quickly gained acceptance, as nozzle-type humidification systems are becoming popular in the printing industry.

- AKIMist® has the best track record in the Japanese printing industry, with over 30 years of strong experience.

- For sheet-fed printing, UV printing, Flexo printing and others, we have the best-suited solutions for all kinds of printing presses.

AKIMist® “E” Dry Fog Humidifier

Our AKIMist®“E” spreads a Dry Fog that humidifies indoor environments without wetting due to its tiny droplet size around 7.5 µm

Case 1: Benefits of a Dry fog humidity control solution in an offset rotary press

- Prevention of stoppage during the operation of the printing machines

- Improvement of the folding accuracy at the folding machine

- Improvement of the production speed

- Reduction of wastepaper

Lorem ipsum dolor sit amet. Nam explicabo esse est beatae commodi est aperiam aspernatur qui explicabo ipsum est molestiae cumque aut veritatis officiis cum cupiditate atque. Aut nulla quia quo reiciendis dolorem ab fuga sunt quo natus natus et velit quae a rerum nulla. Aut reiciendis nihil est minima odio aut neque veniam eum nobis accusantium ut tempora minima.

Electronics industry

An energy-saving humidification method has become the strongest focus of attention.

Common problems caused by static electricity

- Circuit destruction of semiconductors and electronic devices

- Clogging of parts feeder

- Damage (scratch, spot) caused by sparks

- Product transport failure

- Mounting erro

- Adhesion issues

- Adhesion of dust and foreign particles to the product

- Appearance defect due to particles adhesion contamination

Common issues caused by insufficient humidity

- Poor performance of exposure and chip mounter

- Dimensional defects of films, plates, substrates, etc.

- Prolonged maintenance period due to product drying

- Changes in physical properties due to humidity fluctuations

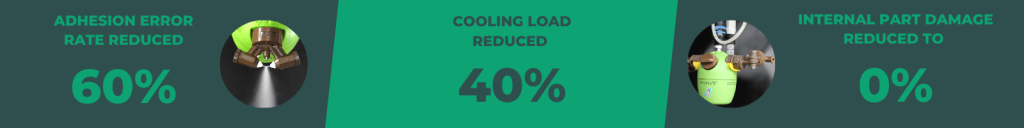

AKIMist®”E” benefits for SMT process

- By maintaining the relative humidity at an appropriate level, it is possible to prevent various problems caused by static electricity.

- The Dry Fog cooling effect reduces the building cooling load.

- With the No. 1 track record as well as 30 years of remarkably good results, we have optimal solutions for a wide range of processes and environments.

- It is also well-suited for clean room humidification.

AKIMist®”E” benefits for SMT process

- By maintaining the relative humidity at an appropriate level, it is possible to prevent various problems caused by static electricity.

- The Dry Fog cooling effect reduces the building cooling load.

- With the No. 1 track record as well as 30 years of remarkably good results, we have optimal solutions for a wide range of processes and environments.

- It is also well-suited for clean room humidification.

Case 2: Benefits of a Dry fog humidity control solution in an IC mounting process

- Improvement of the adhesion of small mounting components

- Reduction of internal destruction due to electrostatic discharges

- Improvement of the production speed

- Energy saving by cooling effect

Steam humidification has no cooling effect and the humidity does not reach 50% in the summer. The more you add air-conditioning to cool down, the more humidity will escape. That is why the Dry Fog humidification is optimal to save energy cost as it also has a cooling effect while humidifying.

Plastic industry

An efficient humidity control allows to create an environment free of static electricity which prevents quality defect.

Common problems caused by static electricity

- Dust and foreign particles adhesion on the product

- Plastic products sticking together

- Discharge ignition of solvents and raw materials

- Sealing and packaging failure

- Electric shock to workers

- Scratches due to discharge

Common issues caused by insufficient humidity

- Dimensional defects of the product

- Changes in physical properties due to humidity fluctuations

- Rise of dust particles

- Risk of employees catching a cold

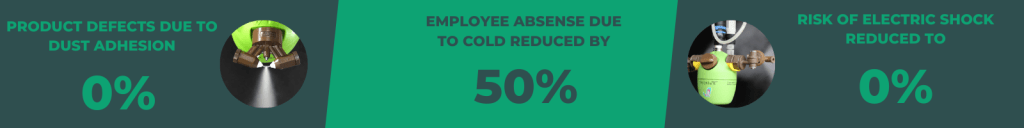

AKIMist®”E” benefits for Plastic manufacturing process

- Plastic material induces various electrostatic disorders due to its property of being easily charged.

- As a measure against dust adhesion, we propose spot humidification mainly in the punching process and inspection process.

- By controlling the relative humidity level around 50%, not only is the production more efficient, the temperature level around the molding machine is also lowered by the cooling effect of the Dry Fog, thus, saving energy.

Case 3: Benefits of a Dry fog humidity control solution in a container manufacturing process

- Prevention of dust and foreign particles contamination during molding

- Reduction of internal destruction due to electrostatic discharges

- Measure against cold during winter

- Prevention of product defects due to dust adhesion

Other benefits of using the AKIMist® Dry Fog Humidifier

Energy and cost

AKIMist is extremely energy-efficient and uses up to 83% less energy than conventional humidification systems.

AKIMist cools around 2 degrees while controlling the humidity level. It reduces 20% of the energy used for air-conditioning and thereby saves cost.

AKIMist can be used for spot humidification and be placed directly by the source of issue. This reduces the price significantly as only a few units may be needed.

Installment and maintenance

AKIMist requires very little maintenance compared to other humidification equipment. In addition, it is very easy to maintain as it is installed within the factory and hanging from the ceiling or wall.

AKIMist is easy to install and can be fitted into any current HVAC design. AKIMist can be installed with a wall or ceiling fitting or

even as a portable option.

AKIMist is very compact. Like the size of a 5 inch smartphone. This makes it easy to fit into tight factory spaces.

Health and Environment

AKIMist can maintain an ideal humidification level with the help of a sensor. This significantly reduces the build-up of static electricity in a factory and reduces errors and scrap.

Due to the small size droplets, which are as small as dust particles, these droplets can suppress the dust. In addition, the increased humidity also helps to suppress dust.

Maintaining a relative humidity level of around 50% will reduce the risk of viruses from spreading between employees. This increases the well-being of the employees and increases productivity.

demo of AKIMist®

Experience AKIMist® Dry Fog technology in person at your facility our ours. It’s also possible to rent a portable unit for a testing period.

Related articles

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”