PCB cleaning

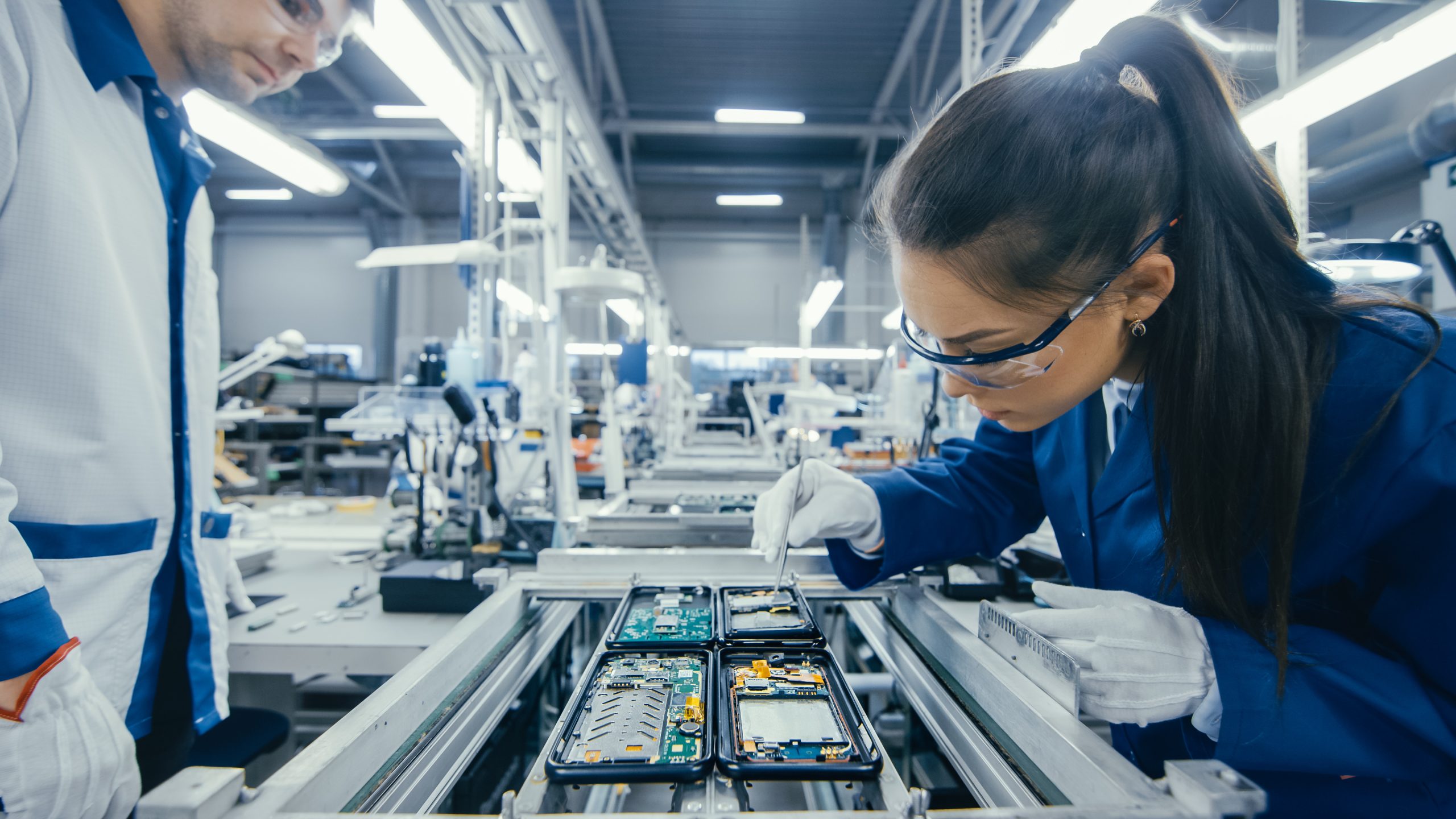

Printed board assembly (PCB) cleaning is a crucial step that follows various chemical treatments such as etching, developing, and stripping. Cleaning ensures that any residual chemicals or contaminants are removed from the PCB surface, preventing potential issues such as corrosion, electrical shorts, or contamination of subsequent processes.

Different types of PCB cleaning can be done with spray nozzles and air nozzles:

- Before the polishing process

- After the developing process

- During the etching process

- After the etching process

PCB cleaning before the polishing

The cleaning process before the polishing begins is an important step. The PCB surface needs to be thoroughly cleaned to remove any contaminants such as dust, oils, or residues left over from previous manufacturing steps.

For this cleaning process, we offer 2 different types of spray nozzles, both with an outstanding wear resistance due to their ceramic orifices:

CMP cleaning

CMP cleaning in semiconductor manufacturing is the crucial post-processing step to remove contaminants, such as slurry particles and chemical by-products, left behind after Chemical Mechanical Planarization (CMP).

Ikeuchi’s JJRP-PTFE spray nozzle line-up can clean about 30 wafers at a time. Due to its material composition made of excellent wear-resistant PTFE (polytetrafluoroethylene) and injection molded PVDF (polyvinylidene fluoride), it is highly resistant to chemicals.

CMP-pad cleaning

The CMP-pad must be cleaned frequently in order to prevent transferring contaminants like flux, solder paste, oils, and dust to the next board. This can cause corrosion, short circuits, and signal interference.

Ikeuchi’s VVEA spray nozzle is ideal for CMP-pad cleaning due to its high spray impact with thin flat spray pattern and uniform distribution. Due to its semi-fine atomization it has a mean droplet diameter of 50μm

PCB cleaning after the developing process

Once the developing process is complete, the PCB is rinsed thoroughly to remove any residual developing solution and to stop the development reaction. This step is crucial to prevent overdevelopment or underdevelopment of the photoresist. For this rinsing process we offer 3 different types of spray nozzles:

For this cleaning process Ikeuchi’s INJJX nozzle is ideal due to its chemical and wear resistant material composition. The quick-detachable design helps to greatly reduce maintenance time.

PCB cleaning during etching process

During the etching process, the PCB is immersed in an etchant solution, typically containing chemicals such as ferric chloride or ammonium persulfate. This process continues until all unwanted copper has been removed. Once the etching process complete, the PCB is rinsed.

For this process we offer two types of spray nozzles which have been developed especially for the post-etching process; INJJX-Y and JJRP. Both spray nozzles are made of polypropylene resin, which means that they have a very high chemical resistance and heat resistance.

Find them here:

PCB cleaning after the etching process

After the etching process, the stripping process takes place. This is the step where the remaining photoresist is removed from the PCB. For this process, we offer 4 different types of chemical resistant spray nozzles:

Blow-off after PCB cleaning

Airblow in the PCB process is when compressed air is used to remove excess water, chemicals, or contaminants from the surface of the PCB. This process is typically employed after rinsing or cleaning steps to ensure that the PCB surface is thoroughly dried and free from residual moisture or contaminants before proceeding to the next manufacturing or assembly step. For this step we offer our TAIFUJet series, which is a line of compressed air nozzles. Their unique and compact design takes the surrounding air and multiplies the airflow, producing a powerful air blow with high spray impact, minimal air consumption and minimal noise levels. Find it here:

Related articles

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”