Atomization spray nozzles

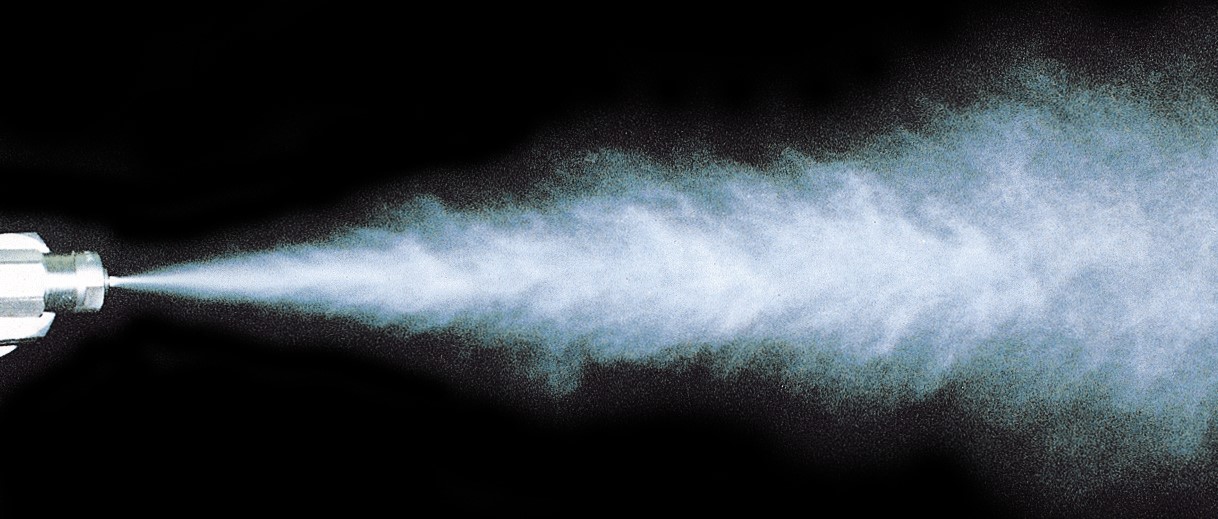

An air atomizing spray nozzle (pneumatic spray nozzle) utilizes a high velocity flow of compressed air and has a number of features compared to a hydraulic spray nozzle:

- Excellent atomizing performance

- Large turn-down ratio

- Large free passage diameter

The 3 features

- Excellent atomizing performance

An air atomizing spray nozzle is capable of producing fine atomization with a mean droplet diameter of 10 μm or less, which is difficult with hydraulic spray nozzles. - Large turn-down ratio

Air atomizing spray nozzles have large turn-down ratios of spray flow-rate with little variation in droplet size and spray distribution. This makes them ideal for spray flow adjustable nozzles. - Large free passage diameter

Air atomizing spray nozzles have larger free passage diameters than hydraulic spray nozzles, which is effective for reducing clogging problems

What type of liquid can be applied?

- Water

- Deoderant

- Alcohol

- Anti-electrostatic agent

- Aqueous amonia

- Surface treatment agent

What type of gas can be applied?

- Compressed air (most common)

- N2

- Steam

Air liquid mixing systems

Compressed air flows in the center of the nozzle, while liquid flows along its circumference. This type provides an important benefit with a larger free passage diameter which minimizes clogging.

Liquid flows in the center of the nozzle, while compressed air flows along its circumference. This type of nozzle is selected for wide range of applications. Larger orifice size can be designed on demand while the spray droplets become a little coarser.

Even at a low air-water ratio, the increased velocity of the droplets results in a strong impact force. Furthermore, the turn-down ratio is larger and this type is suitable for cooling objects in high temperature range.

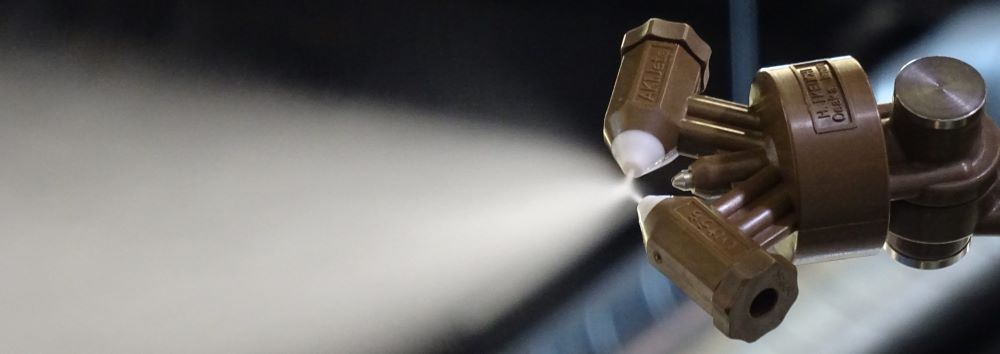

External mixing type

Compressed air and liquid are mixed outside the

nozzle. Hence, this type clogs the least. This is also

classified into inner air type and outer air type.

Impinging type

Air-stream entraining fine fog jets out from the

nozzle and impinges against another air-stream of

the same nature for shattering the fog into even

finer, more-uniform droplets. This is an original invention by Ikeuchi. Read more here: AKIMist

Liquid feeding system

Liquid pressure system

This systems uses pressurized liquid method where a pressurized liquid is supplied separately to a pneumatic nozzle.

Liquid siphon system

This system uses uses compressed air to suck up liquid. The spray capacity differs depending on liquid

siphon height (H).

Spray pattern

Spray pattern means the cross sectional shape of the spray. As illustrated, spray patterns are available in cone spray (hollow cone spray and full cone spray), flat spray, and liquid film-like spray. It is important to select a spray pattern suited for each application, thus, delivering the optimal nozzle performance.

A hollow cone spray pattern is suitable for applications where you wish to achieve a ring-shaped distribution with minimal liquid in the center. Applications include humidification, gas scrubbing, dust control, and moisture control.

A full cone spray pattern is suitable for applications where you wish to achieve an even spray distribution in a wide narrow spray. Applications include humidification, conveyor belts, car wash, pollution control, and moisture control.

A flat spray pattern is suitable for applications where you wish to achieve a mountain-shaped distribution. Applications include cooling and coating.

A film-like spray pattern is suitable for applications where you wish to achieve a uniform distribution distribution. Applications include cooling and coating.

Take a look at our selection of air atomizing nozzles

Advantages of air-atomizing nozzles

- Excellent atomizing performance

- Large turn-down ratio

- Large free-passage diameter

Related articles

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”