What are the different types of spray nozzles?

We generally differ between hydraulic and pneumatic when talking about spray nozzles. Hydraulic nozzles only use liquid pressure, whereas pneumatic nozzles use air and liquid pressure.

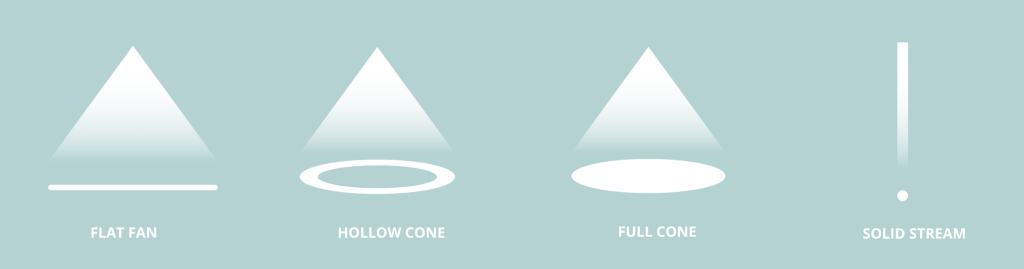

Hydraulic spray nozzles can be divided into 4 different types of spraying patterns:

- Flat fan

- Hollow cone

- Full cone

- Solid stream

Flat fan nozzles

Flat fan nozzles, also known as flat spray pattern nozzles, are know for their mountain-shaped spray pattern or even distribution. Read more here

Purpose:

- Cleaning

- Spraying water or chemicals

- Cooling

- Paper or metal trimming

Hollow cone nozzles

Hollow cone nozzles are know for their donut-shaped spraying pattern. Read more here

Purpose:

- Cleaning

- Spraying water or chemicals

- Cooling and washing gases

- Cooling of fruits and vegetables in supermarkets and cold-storage production department

- Humidifying and chemical reactions

- Paper or metal trimming, etc.

Full cone nozzles

Full cone nozzles spray in a cone-shaped manner. As the name suggests, the entire surface is sprayed within the cone. Read more here

Purpose:

- Cleaning

- Spraying water or chemicals

- Cooling

- Paper or metal trimming

Solid stream nozzles

A solid stream nozzle spray in a constant solid stream. This can either be in a one-stream, two-stream or a 7-stream pattern. Read more here

Purpose:

- Cleaning

- Spraying water or chemicals

- Cooling

- Paper or metal trimming, etc

Pneumatic types of spray nozzles

Pneumatic nozzles mix gases into liquids and atomize them into a spray using a high-pressure pump and an air compressor. They can be used for a wide variety of applications, as they can generate finer fogs than hydraulic spray nozzles and can also spray highly viscous liquids. They can be divided into 3 different types: Internal mixing type, external mixing types and impinging type.

Internal mixing type

In an internal mixing nozzle, the air and gas meet inside the nozzle and mix before it leaves the spray nozzle. This leads to a consistent droplet size and distribution generally with a mean droplet of 100 μm or less. Read more here

- Moisture control

- Dust suppression

- Cooling

- Cleaning

External mixing

The external mixing type produce fine droplets sprayed in a fan pattern, featuring a structure that minimizes liquid dripping when the spray shuts off. These nozzles can be operated either by liquid pressurization or liquid suction. Read more here

- Spraying oil

- Spraying lubricant

- Spraying honey etc.

Impinging type

Atomized droplets are impinged against each other creating ultrasonic waves, which results in creation of a uniform distribution of even finer droplet sizes. Read more here

- Humidification

- Dust suppression

- Cooling

- Moisture control

- Dust suppression

- Cooling

- Cleaning

Related articles

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”