Wetting process

Ikeuchi provides a number of solutions for the wetting process in PCB

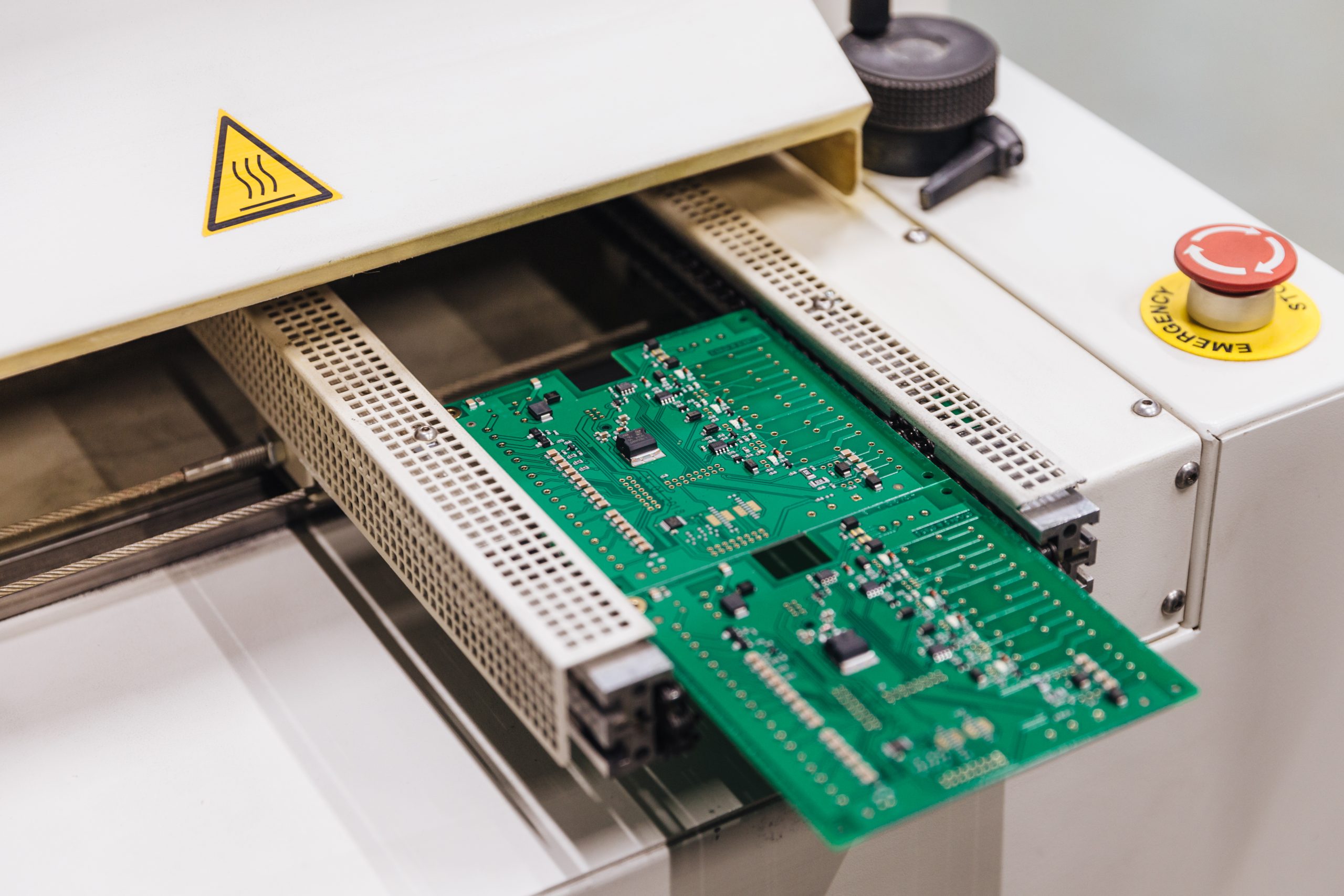

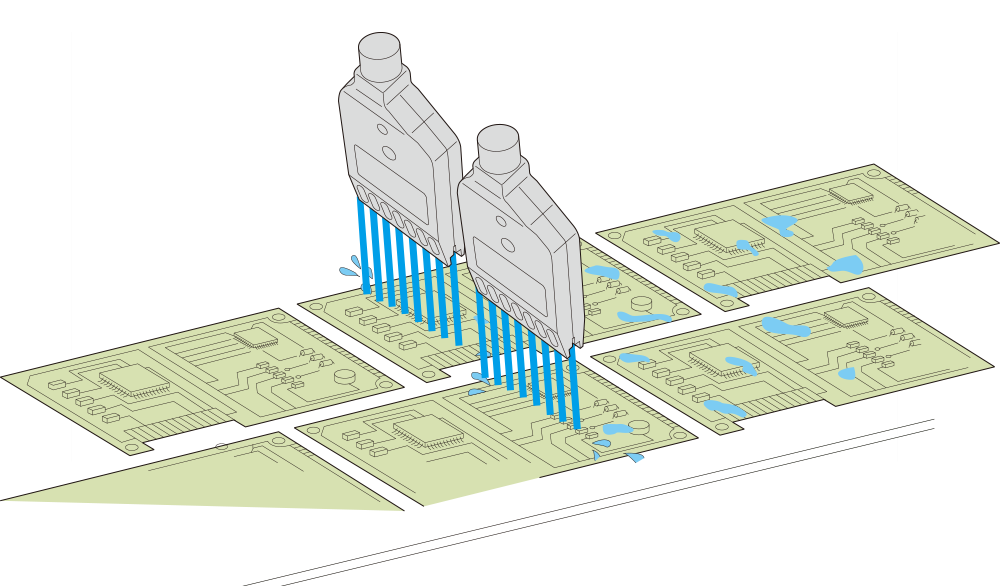

PCB wetting process

We provide a number of spray nozzle solutions for the wetting process in PCB. It is important to choose nozzles of high quality in order to avoid issues such as disparate spray capacity, uneven spray impact for precision cleaning, low washing ability etc.

Highlights

- PCB wetting process

- Prevent disparate spray capacity

- Prevent uneven spray impact

- Higher washing ability

- High wear resistance

Improve the PCB wetting process with spray nozzle technology

Polishing process

The cleaning process before the polishing begins is an important step. The PCB surface needs to be thoroughly cleaned to remove any contaminants such as dust, oils, or residues left over from previous manufacturing steps. For this cleaning process, we offer 3 different types of spray nozzles, all with an outstanding wear resistance due to their ceramic orifices.

Developing process

Once the developing process is complete, the PCB is rinsed thoroughly to remove any residual developing solution and to stop the development reaction. This step is crucial to prevent overdevelopment or underdevelopment of the photoresist. For this rinsing process we offer 3 different types of spray nozzles:

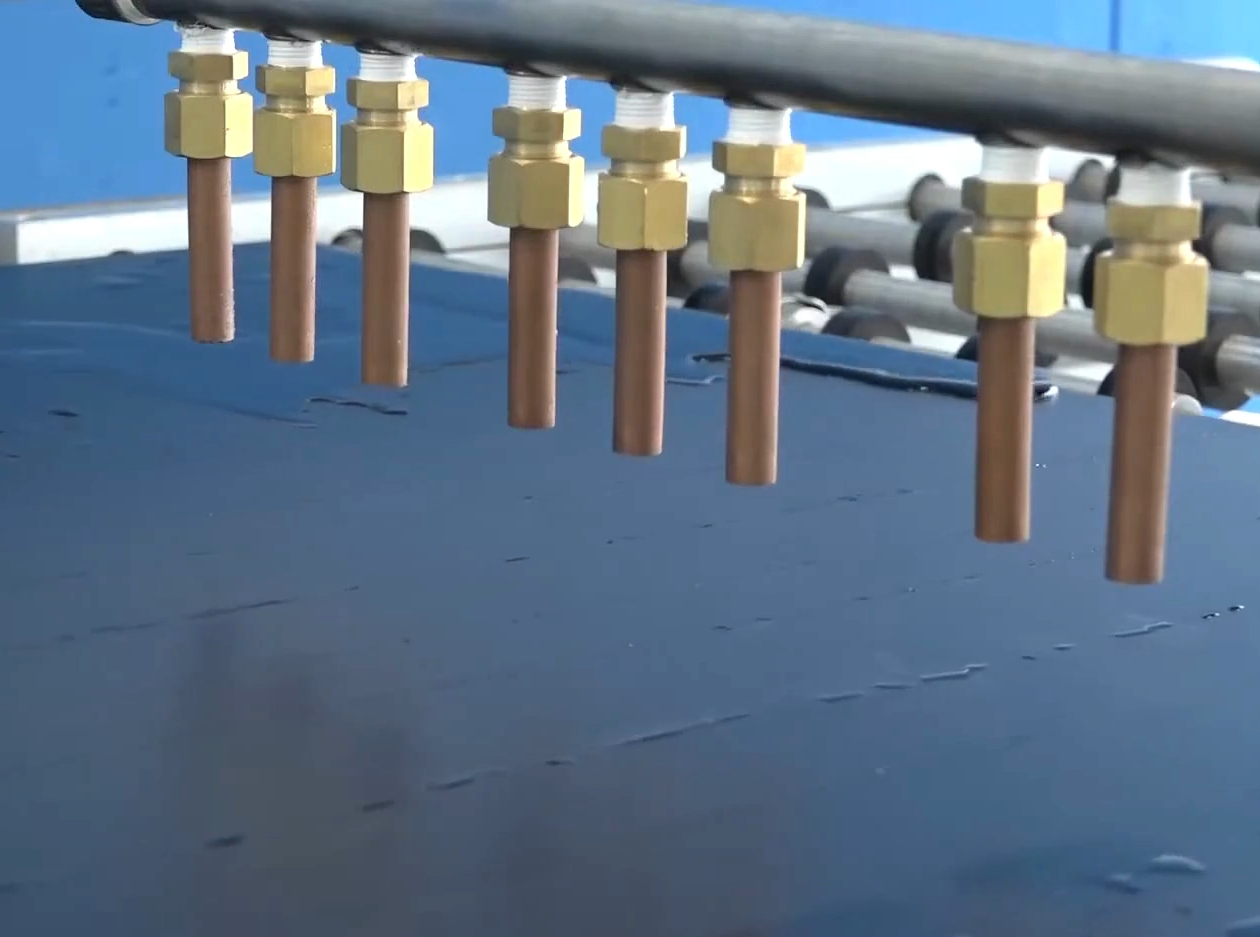

Etching process

During the etching process, the PCB is immersed in an etchant solution, typically containing chemicals such as ferric chloride or ammonium persulfate. This process continues until all unwanted copper has been removed. Once the etching process is complete, the PCB is rinsed.

For this process we offer two types of spray nozzles which have been developed especially for the etching process.

PCB stripping process

The stripping process is the step where the remaining photoresist is removed from the PCB after the etching process. For this process, we offer 4 different types of chemical resistant spray nozzles:

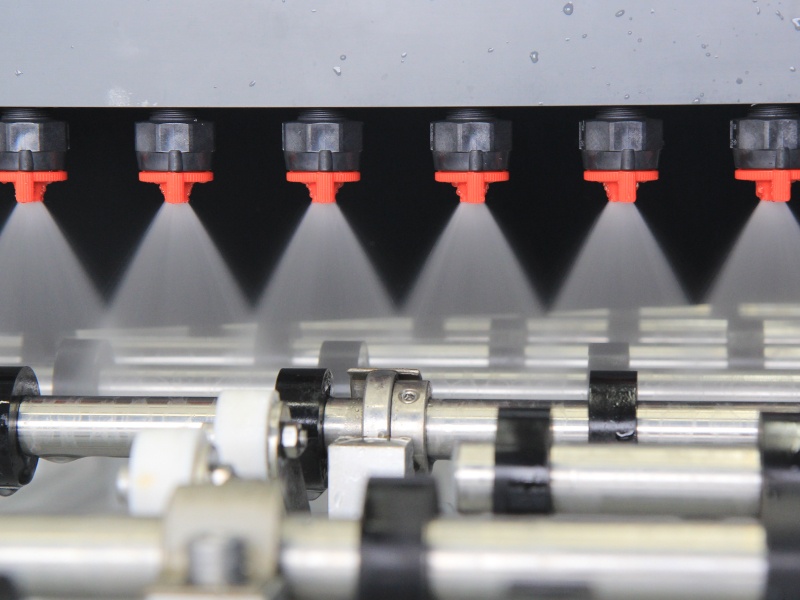

PCB rinsing process

The rinsing process is a crucial step that follows various chemical treatments such as etching, developing, and stripping. Rinsing ensures that any residual chemicals or contaminants are removed from the PCB surface, preventing potential issues such as corrosion, electrical shorts, or contamination of subsequent processes. We offer a number of spray nozzles for precision cleaning:

Air blow off

Airblow in the PCB process is when compressed air is used to remove excess water, chemicals, or contaminants from the surface of the PCB. This process is typically employed after rinsing or cleaning steps to ensure that the PCB surface is thoroughly dried and free from residual moisture or contaminants before proceeding to the next manufacturing or assembly step.

For this step we offer our TAIFUJet® series, which is a line of compressed air nozzles. Their unique and compact design takes the surrounding air and multiplies the airflow, producing a powerful air blow with high spray impact, minimal air consumption and minimal noise levels.

- High chemical resistance

- High precision spraying

- High wear resistance

- Reduced water consumption

Related products

Case studies

Conveyor belt sorting system with air nozzles

Tank cleaning for miso paste production process

Customer stories: real experiences, genuine satisfaction

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

Experience the impact of Ikeuchi’s precision spray technology and innovative solutions through the voices of industries worldwide. See how we help businesses excel with custom-made solutions and unparalleled reliability.

Stay updated: Ikeuchi news & insights

"*" indicates required fields

Get expert advice:

contact us today

Would you like to know what Ikeuchi can do for your organization? We’re happy to discuss your needs and show how we can solve your challenges. You’ll receive a response from us within 24 hours!

"*" indicates required fields

Call us: +31 (0) 20 820 2175

- Global presence and experience

- The number 1 nozzle manufacturer in Japan

- Japanese Precision Technology

“High quality nozzles. Friendly and helpful customer service”

“With Ikeuchi spray nozzles we are able to save costs as we don’t need to replace them so often as before.”

“When it is about nozzle technology, IKEUCHI are the experts. We always highly appreciated their knowhow and their extremely wide range of nozzles, not to mention their unrivalled AKIMist humidifier”

“When it is about nozzle technology, IKEUCHI are the experts. ”