May 26, 2020

The benefits of Dry Fog in different industries

Benefits of Dry Fog in specific industries

The AirAKI® Dry Fog humidification system has many benefits and are used in various factories such as electronics, printing, paper & pulp, plastic, chemical plants, automotive, textile, agriculture, painting, etc.

Our systems help solving many of our customers issues related to electrostatic discharges, dust adhesion, low humidity level, and even worker’s health management in winter. In this article we will highlight the benefits of dry fog in different cases.

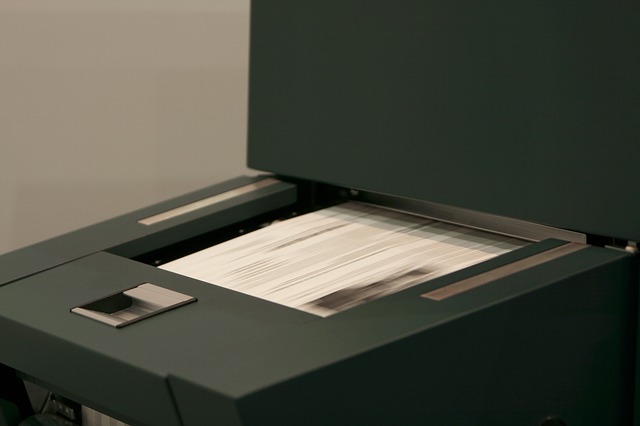

Printing field

Finding a humidity control suitable for each type of printing press and process has a big impact on the production.

Common problems caused by static electricity

- Dust adhesion to plate making

- Poor sticking

- Paper dust adhesion to printed materials

- Folding failure

- Poor paper feeding (two-sheet feeding)

- Ink scattering

- Paper jam

- Ignition of solvent

- Paper misalignment

- Responsiveness of high-speed machine

Common issues caused by insufficient humidity

- Paper break

- Paper joint failure

- Curl due to expansion and contraction of paper

- Punching failure

- Poor dimensional accuracy

- Ink drying

- Poor registration

- Ink stain

- Print wrinkles

- Ruled and back cracks

AKIMist®”E” benefits for Web Offset Printing Process

- AKIMist® has quickly gained acceptance, as nozzle-type humidification systems are becoming popular in the printing industry.

- AKIMist® has the best track record in the Japanese printing industry, with over 30 years of strong experience.

- For sheet-fed printing, UV printing, Flexo printing and others, we have the best-suited solutions for all kinds of printing presses.

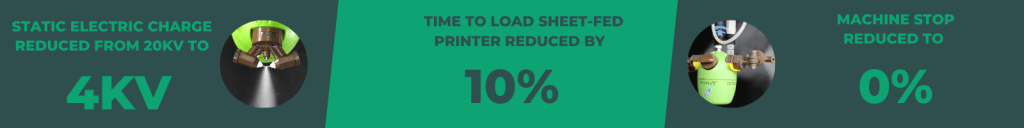

Case 1: Benefits of a Dry fog humidity control solution in an offset rotary press

- Prevention of stoppage during the operation of the printing machines

- Improvement of the folding accuracy at the folding machine

- Improvement of the production speed

- Reduction of wastepaper

Electronics field

An energy-saving humidification method has become the strongest focus of attention.

Common problems caused by static electricity

- Circuit destruction of semiconductors and electronic devices

- Clogging of parts feeder

- Damage (scratch, spot) caused by sparks

- Product transport failure

- Mounting error

- Adhesion issues

- Adhesion of dust and foreign particles to the product

- Appearance defect due to particles adhesion contamination

Common issues caused by insufficient humidity

- Poor performance of exposure and chip mounter

- Dimensional defects of films, plates, substrates, etc.

- Prolonged maintenance period due to product drying

- Changes in physical properties due to humidity fluctuations

AKIMist®”E” benefits for SMT process

- By maintaining the relative humidity at an appropriate level, it is possible to prevent various problems caused by static electricity.

- The Dry Fog cooling effect reduces the building cooling load.

- With the No. 1 track record as well as 30 years of remarkably good results, we have optimal solutions for a wide range of processes and environments.

- It is also well-suited for clean room humidification.

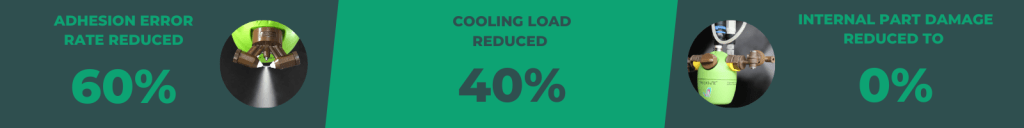

Case 2: Benefits of a Dry fog humidity control solution in an IC mounting process

- Improvement of the adhesion of small mounting components

- Reduction of internal destruction due to electrostatic discharges

- Energy saving by cooling effect

Steam humidification has no cooling effect and the humidity does not reach 50% in the summer. The more you add air-conditioning to cool down, the more humidity will escape. That is why the Dry Fog humidification is optimal to save energy cost as it also has a cooling effect while humidifying.

Plastics field

An efficient humidity control allows to create an environment free of static electricity which prevents quality defect.

Common problems caused by static electricity

- Dust and foreign particles adhesion on the product

- Plastic products sticking together

- Discharge ignition of solvents and raw materials

- Sealing and packaging failure

- Electric shock to workers

- Scratches due to discharge

Common issues caused by insufficient humidity

- Dimensional defects of the product

- Changes in physical properties due to humidity fluctuations

- Rise of dust particles

- Risk of employees catching a cold

AKIMist®”E” benefits for Plastic manufacturing process

- Plastic material induces various electrostatic disorders due to its property of being easily charged.

- As a measure against dust adhesion, we propose spot humidification mainly in the punching process and inspection process.

- By controlling the relative humidity level around 50%, not only is the production more efficient, the temperature level around the molding machine is also lowered by the cooling effect of the Dry Fog, thus, saving energy.

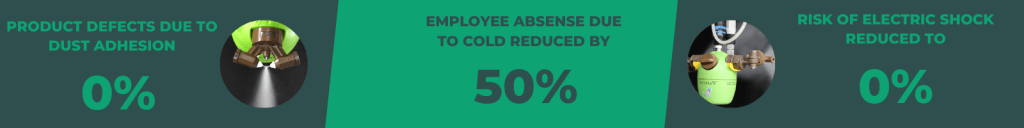

Case 3: Benefits of a Dry fog humidity control solution in a container manufacturing process

- Prevention of dust and foreign particles contamination during molding

- Environmental cooling

- Measure against cold during winter

- Prevention of product defects due to dust adhesion

How can IKEUCHI help?

The above cases clearly demonstrate that a humidification system can be really beneficial for the productivity of manufacturing processes. Would you like to know more about how it can be applied to your specific case? Contact us directly or book a free demonstration of our AKIMist® humidifier in your factory: Book free demo