April 20, 2023

Atomization spray nozzles

Atomization spray nozzles

Atomization is the process of breaking a liquid into tiny droplets or particles.

The methods of atomization can be divided into:

- Hydraulic atomization

- Pneumatic atomization

- “AKIMist®” atomization

Hydraulic atomization

Hydraulic atomization consist only of water supply. The liquid is pushed though a tiny orifice at high pressure.

In the case of hydraulic atomization, the spray output will often vary between larger and smaller droplets due to the lack of compressed air. It is not possible to spray a fine mist with this method. The sprayed amount will also be limited due to the very small orifice. This method can be used in cases where a small consistent droplet size is unimportant, for instance in rinsing or cleaning. The technique requires high maintenance due to the pressure on the small orifice.

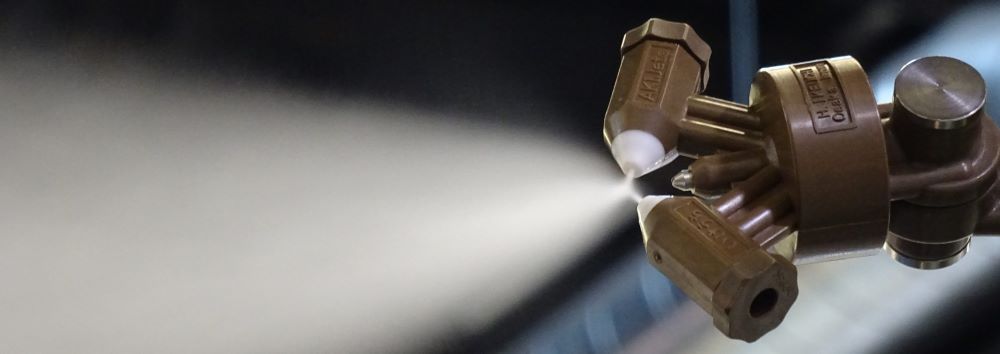

Pneumatic atomization

Pneumatic atomization consist of water and compressed air supply.

In the case of pneumatic atomization, it is more efficient than hydraulic atomization and it is possible to produce smaller droplets which sometimes evaporate. However, pneumatic atomization has its limitations in regards to producing a consistent size of tiny droplets (below 10µm) and it is an inefficient and energy-consuming way to obtain this.

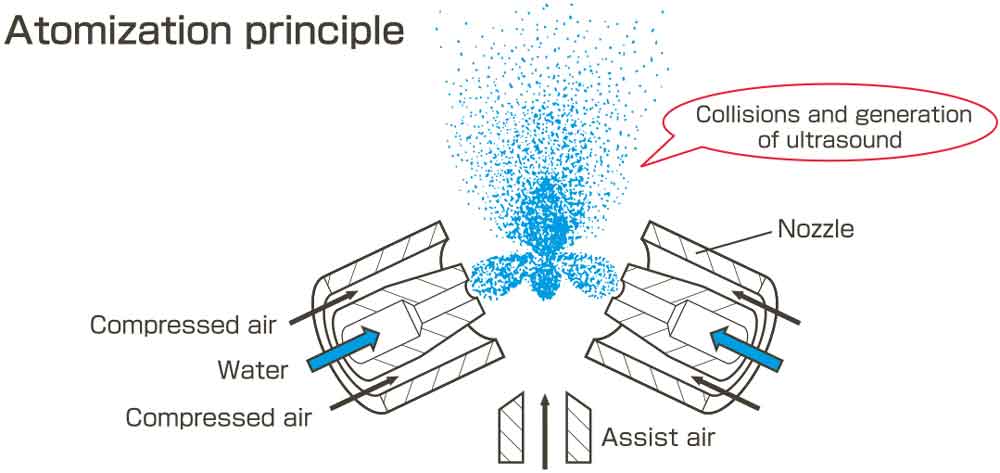

AKIMist® atomization

The atomization technology which was invented for AKIMist®, combines water supply, compressed air and ultrasonic waves. Liquid is sent into the two spray orifices of the nozzle tip and is then atomized inside the orifices by shearing force as they collide. Shear force is the frictional force between the two liquids as they move at different speeds. The sheared liquid is then further re-atomized by 33,000–40,000 Hz ultrasonic waves. This way, an ultra-fine “dry fog” is created with a uniform spray droplets distribution.

Non-wetting

These droplets are so small (below 10µm) that they will bounce back from the surface they touch without bursting. This makes AKIMist® atomization the preferred choice among many production facilities to protect machinery and equipment from water damage.

Advantages of AKIMist® E:

- Humidifying with water without wetting equipment (no water drops)

- Prevents static electricity at production site and offices

- Easy installation by adding on to existing HVAC

- Easily adaptable to changes in the floor layout

- Its double advantage of cooling while humidifying

- Reducing product loss and scrap

- Improving product quality

- Highly energy efficient

- Low maintenance

Read more about AKIMist and droplet sizes here:

The AKIMist®“E” Dry Fog Humidifier

Read more about droplet sizes here: