November 26, 2019

Detecting nozzle performance problems and when to replace them?

Nozzles are essential to many industries because they allow very precise and powerful work to be cost-efficient. However, damaged nozzles can slow down your activity without you even knowing it. We will see today how nozzles can be damaged and how important it is to take care of nozzles and replace them from time to time.

Why should you pay attention to the nozzle’s performance?

Nozzles are very small industrial pieces. They are relatively fragile and need to be taken care of. Even if the clues showing your nozzles are damaged are really not obvious, the consequences can be very detrimental to your production process. You can see in this article the comparison between good and bad nozzle performance.

In this article, we will see the importance of taking care of nozzles and how to make them last longer.

How do nozzles get damaged?

A lot of factors come into consideration when picking the right nozzle. In fact, each application necessitates a thorough study to determine which type of nozzle, which material, which spray pattern fits. Picking the wrong nozzle will lead to bad results and also accelerate the time when nozzles are damaged.

Several criteria change the lifespan of a nozzle :

- The material: steel, ceramic, plastic, each of them has specific characteristics and resistance features. For example, Stainless Steel has better resistance than PVC, but PVC is more suitable to spray acidic liquid.

- The average length of use: if a nozzle is used every day for an application, its longevity will be lower. It will also strongly depends on the application and the liquid sprayed.

- The chemicals: if the nozzle sprays chemicals, the level of corrosivity can increase the damage to the nozzle and force you to change it more often.

- The maintenance process: if the cleaning or the maintenance process is too rough, it can permanently damage the nozzle.

- Wrong utilization: if you use a nozzle for something else than the approved application, it will probably damage it.

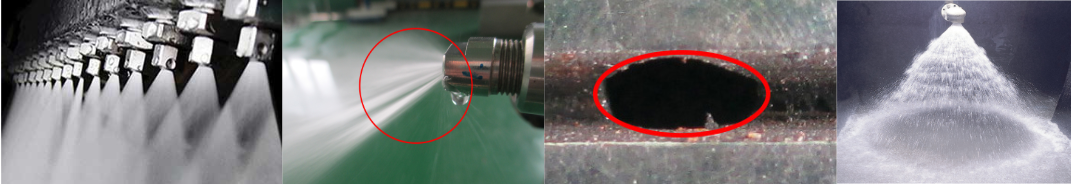

If a nozzle is damaged, its orifice can be scratched or deformed, thus leading to several malfunctions.

Clues of nozzle deterioration

It is not always easy to spot if a nozzle is deficient but there are several clues :

- Uneven spray pattern and distribution: if you notice an uneven distribution of spray pattern, such as lines of water in the spray or water dripping, it could mean the nozzle is clogged.

- Bad results: if the results of your application significantly decrease, this might mean that your nozzles are no longer functional.

- Increased water expenses: if your water expenses related to the use of nozzles is increasing, this is a sign that your nozzles are not working properly.

- Pressure loss: if your system suffers pressure loss, it might mean that there is something wrong with your nozzles.

- Scratched nozzle: the orifice of your nozzle can be scratched during maintenance. This irreversible damage will disturb the proper functioning of the nozzle. You must be very careful during the maintenance process of your nozzle and clean it with a softer material.

If you experience these kinds of issues, don’t hesitate to contact our engineering team.

Consequences and financial loss of damaged nozzles

Damaged nozzles are not only underachieving, thus lowering the quality of your end product, but they also can be a financial hole. They are three main costs that will develop if you keep using worn nozzles:

- water costs,

- chemical costs,

- production inefficiency.

Indeed, using worn nozzles will lead to a major increase in chemicals and water consumption. It will also interfere greatly with your production process.

If you need advice or to change your nozzles, contact us!

How to improve the lifespan of your nozzles?

Depending on your application, you should set up a maintenance program and stick to it. Nozzles are precision pieces and you should be very careful when cleaning them. For example you could brush them with a softer component than its materials. Or use an ultrasonic washing device to remove small clogged particles.

If you ever detect a malfunction with your nozzle, contact us or use replacement nozzles.

The best way to keep your nozzles in good shape for the longest time is to pick the best nozzle for your application (series, material) and to do a proper maintenance every 2 weeks or month.

If you have any questions or wish to contact us, don’t hesitate one second and click on the button below.