Benefits of the AKIMist® Dry Fog Humidification

As “The Fog Engineers”, IKEUCHI is renowned for its original and unique Dry Fog system called AKIMist®. Since 1979, when the innovative ultra-fine fog nozzles AKIJet® (patented worldwide) was invented, AKIMist® was successfully installed in factories worldwide.

Its unique non wetting fog is ideal for a wide range of industries: from clean rooms to electronics, automotive, plastic making, and even mushroom farming!

Dry Fog humidifier AKIMist® – General benefits

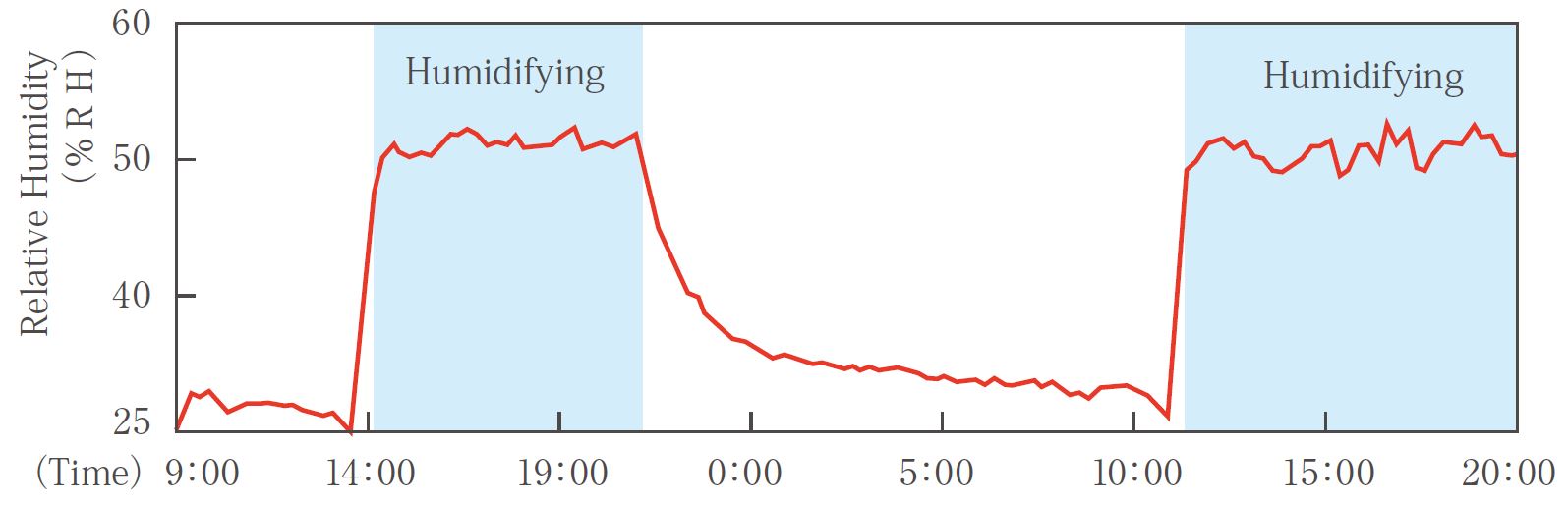

Accurate humidity control of large areas:

The system enables the most suitable and optimal humidification solution without wetting thanks to the skill-rich engineering design and the Dry Fog which is the tiniest and the most stable droplets (7.5μm on average).

Reduced CO2 consumption:

Thanks to its cooling effect, the cooling load is reduced by 2°C, which represents 580 tons* of CO2 saved from air conditioning unit.

Reduced air conditioning cost significantly:

60.000EUR of running cost saved in a year by replacing the steam type of system to the Dry Fog AKIMist® system.

Testimonials regarding the Benefits in terms of Productivity and Operational improvement rate

Here are the main benefits that have been noticed on customers’ sites for 5 different industries.

Printing industry

- Improvement by 40% of RPM on Rotary Press thanks to a reduction of shutdown caused by ESD

- Product quality improved thanks to a decrease in operational issues caused by ESD (like back printing, whiskers, etc.)

- Decrease dust adhesion issues on films and papers (Reduction of streak defect)

- Enabled to operate with thinner materials which are more sensitive for ESD

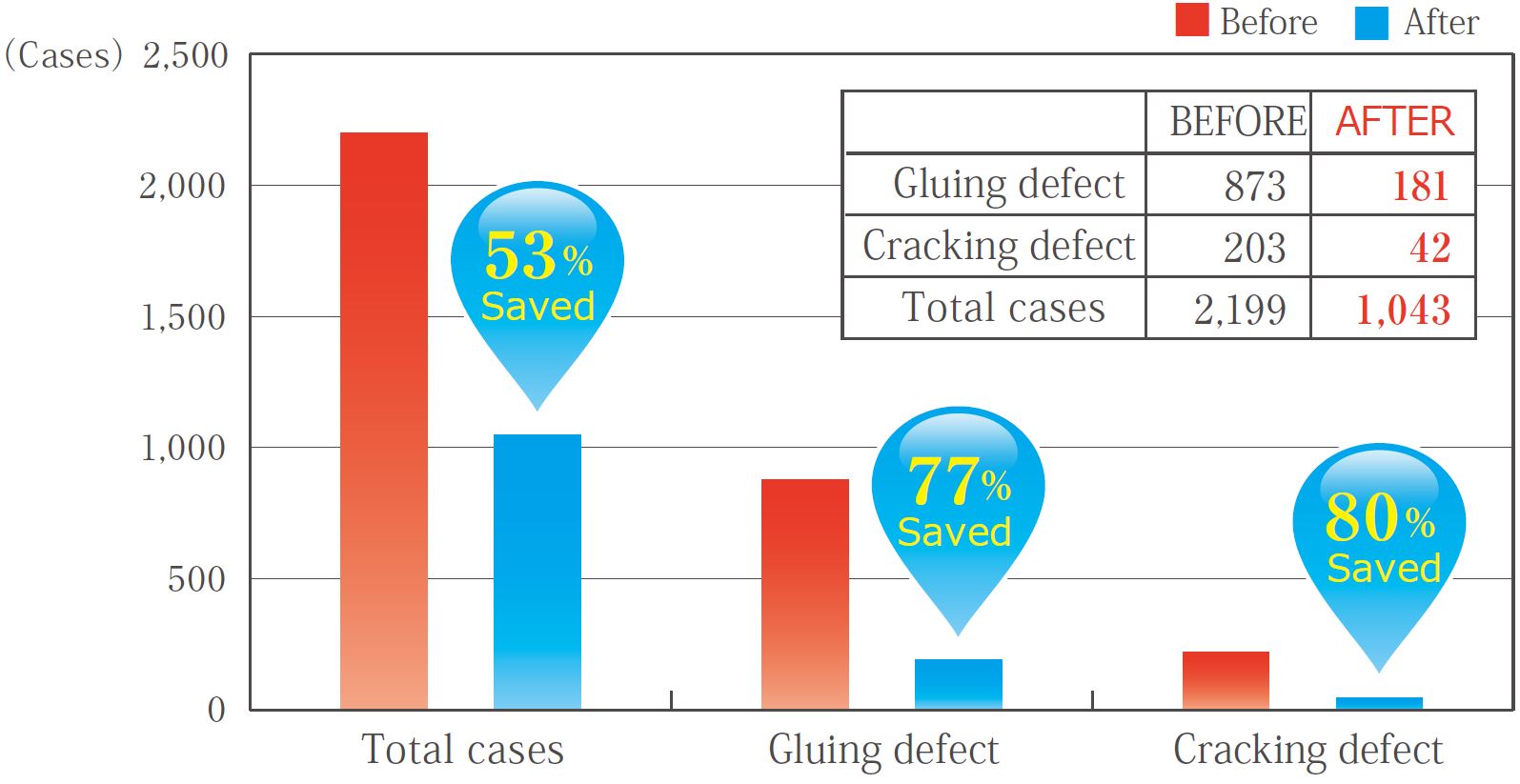

- Improvement of folding quality with the defect reduced to 1/3

- Stable paper quality and shortened registration time due to less shrunk on materials

- Zero defect of misalignment at stacker band

- Reduced the issues of double feeding and misalignment, Improvement of productivity improved

- Improved printing stability and misalignment reducing reprinting and color shift issues

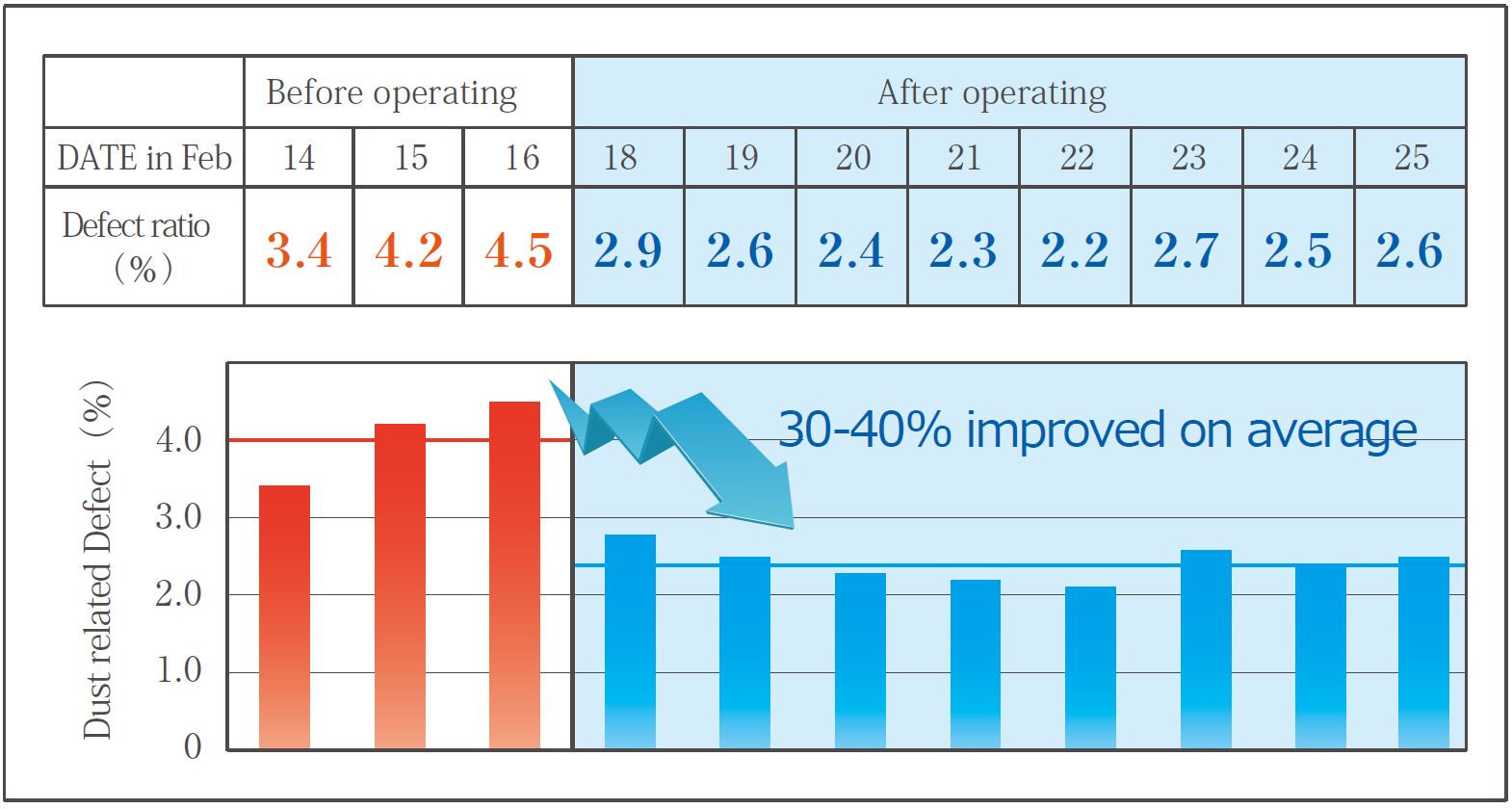

Dust related defect improved by 30-40% on average and waste due to defects reduced by 1.5%

More details about different printing devices

Electronics industry

- Drastically improved ESD related issues and damages due to electrostatic breakdown

- Decrease in defect rate due to Zero circuit damage caused by dust adhesion in the assembling process of PCB

- Reduction by 30% in air conditioning cost in production area thanks to the AKIMist®’s cooling effect

- Ideal environment for products by keeping a stable humidity level at 60% (+/- 3%) RH

- Fully adjustable installation for humidity requirement even when machines and devices are relocated/ renewed

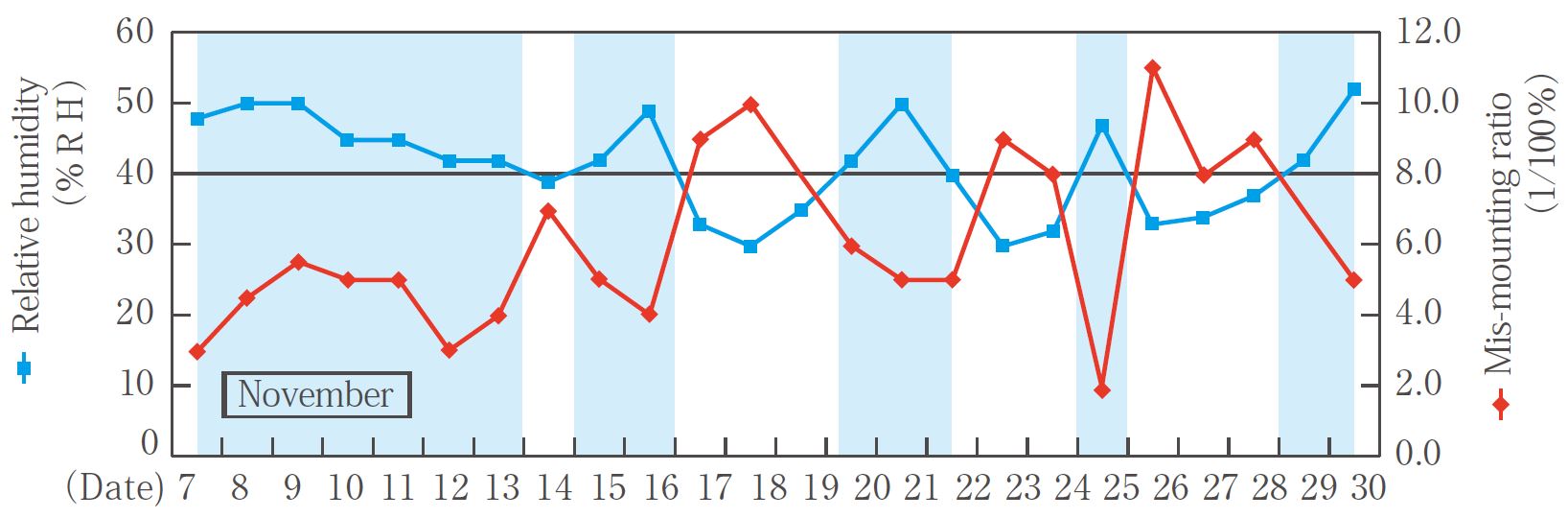

Improved Mis-mounting defect

More details about the electronics industry process

Plastics industry

- Reducing risk of firing in foaming and cutting after injection, and in printing processes

- 10%+ of productivity increased thanks to reduced risk of fire on flammable solvent

- Reduced defect rate due to sticking after molding, Inspection process improved by 10%

- Time spend on packing task in shipping process reduced by 10% thanks to less ESD on products

- More stable quality of products with less time of inspection thanks to less defects regarding foreign particles stuck in production

- Defect ratio improved by 5%+ thanks to no dust adhesion during the film manufacturing process

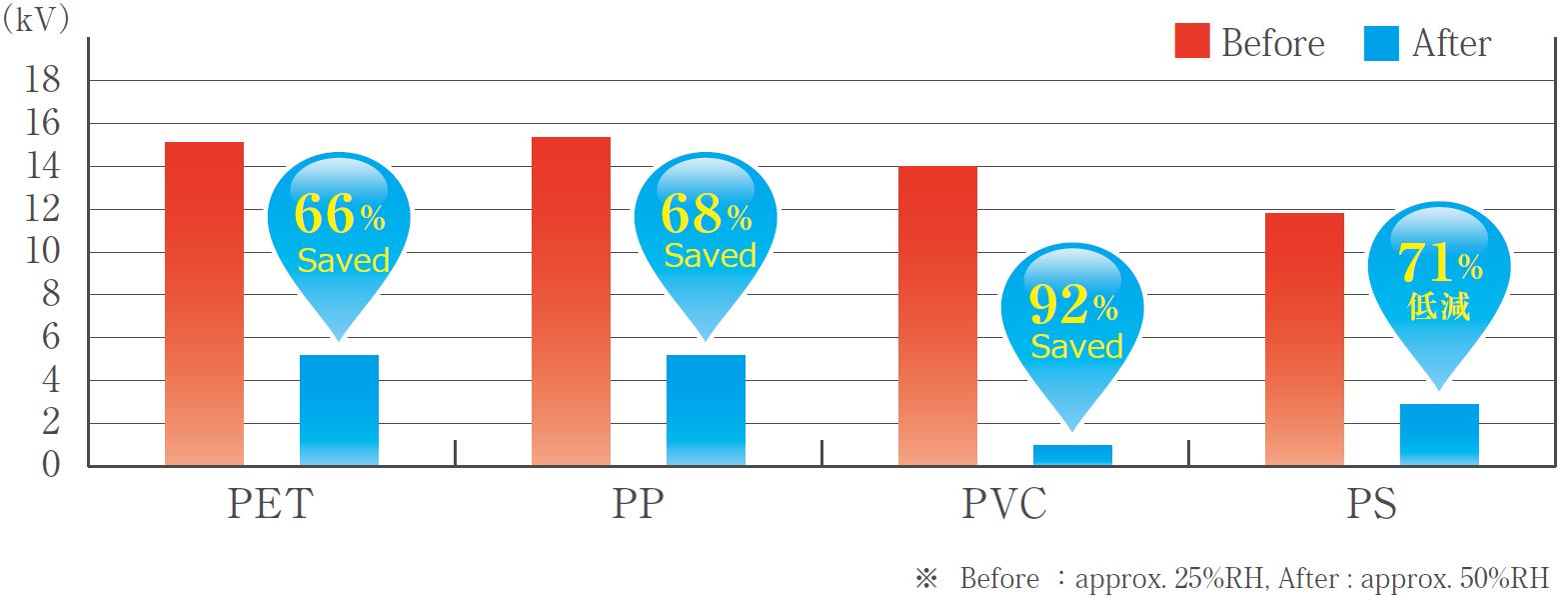

Less electrostatic charges, Better productivity

Painting industry

- Drastically improved the risk of firing in ink stores, mixing rooms, and filling processes

- Safety improved and risk of ignition drastically reduced around the reaction kettle and mixer

- Productivity increased by 10%+ in painting area thanks to a reduction in dust adhesion issues

- Paint quality improved thanks to a reduction by 20%+ of dust related defects

- Cissing related defects and repelling occurrence in the painting process down to Zero

- Significant decrease of absenteeism rate in winter with less employees catch colds

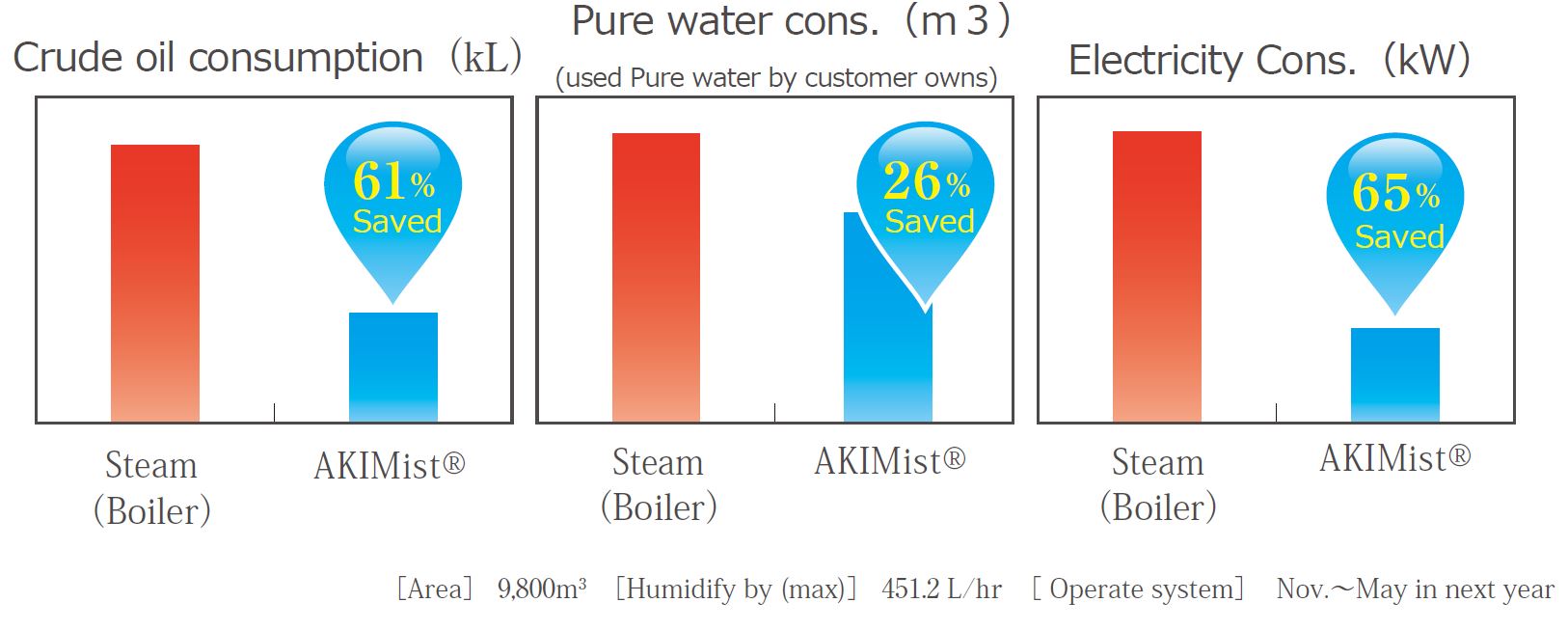

- Maintenance cost saving of ca. 15,000 EUR on an annual base, by replacing the boiler steam humidification system to the AKIMist® humidifier

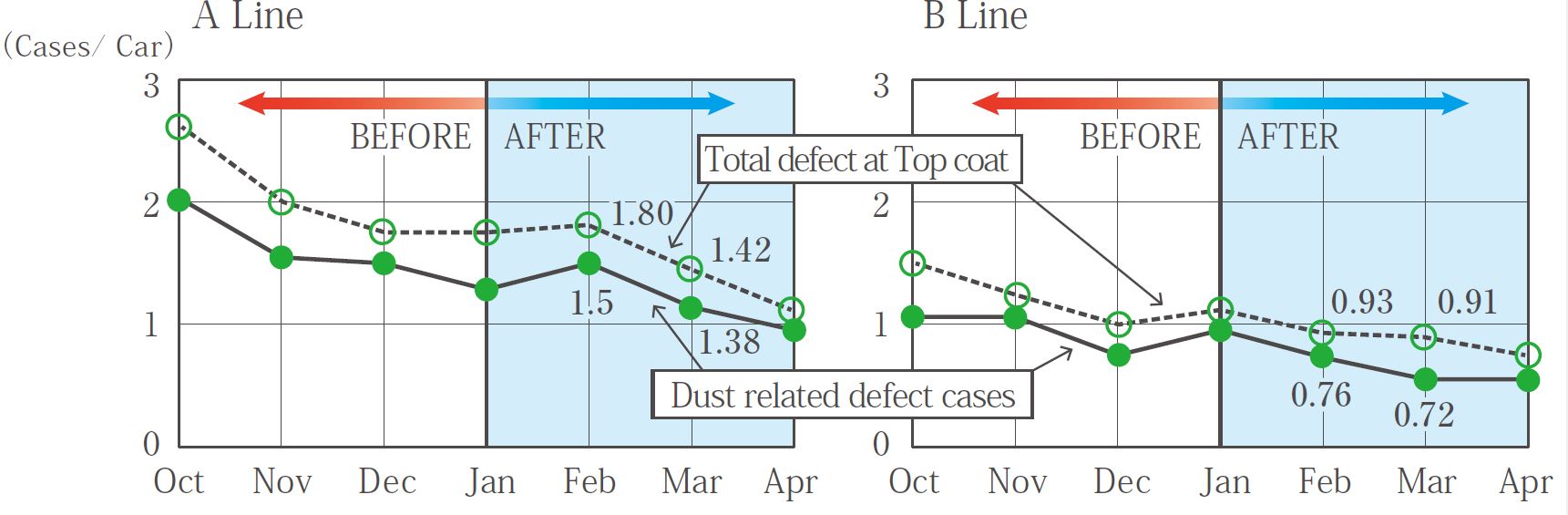

Dust related defect reduced drastically

More information about painting in the Automotive industry

Packaging, Cardboard industry