July 22, 2019

Compressed air safety regulation

How to reduce risks when using compressed air?

When you use air nozzles and air guns with compressed air, there are two important aspects to take into consideration:

- Noise level compliance for a safe working environment;

- Blowing performance for productivity and efficiency.

Importance of a safe working environment for manufacturing processes

There are several regulations worldwide which determine the definition of a safe working environment applied to noise level exposure.

In Europe, the general directive is the EU Directive 2003/10/EC – noise; in Great Britain the HSE determined the the noise level with The Control of Noise at Work Regulations 2005; and in the US, OSHA sets the requirements for Safety and Health.

Let’s have a quick explanation and interpretation of these regulations.

Acceptable noise level in a factory

- According to the EU Directive 2003/10/EC

The EU Directive 2003/10/EC establishes the requirements for the protection of workers related to noise exposure and especially the risk of hearing loss.

The Directive set the limit of noise exposure to 87 decibels for 8 hours of work day. It also takes into account “the attenuation provided by personal protective equipment (hearing protectors) worn by the workers”.

- According to The Control of Noise at Work Regulations 2005

The HSE determined the maximum level of noise exposure to 85 decibels (daily or weekly average exposure).

- According to OSHA standard 1910.95 Occupational Noise Exposure

OSHA sets the limit on noise exposure to 90 decibels for an 8 hours of work day.

Mandatory measures from the employer

In addition to respect the limitation of the noise level exposure for its workers, the employer has the duty to assess the risk and determine the measure to control the noise exposure.

Hearing protection and recurrent training should be implemented to ensure the right attitudes from the workers and a better outcome to noise exposure.

Nowadays it is mandatory for the employer to find solutions to eliminate the risks caused by noise exposure, to reduce the exposure itself and to implement the latest technologies to control noise.

Noise exposure when using air nozzles with compressed air in a factory

So how can you comply to the EU Directive and OSHA standard when using air nozzles with compressed air?

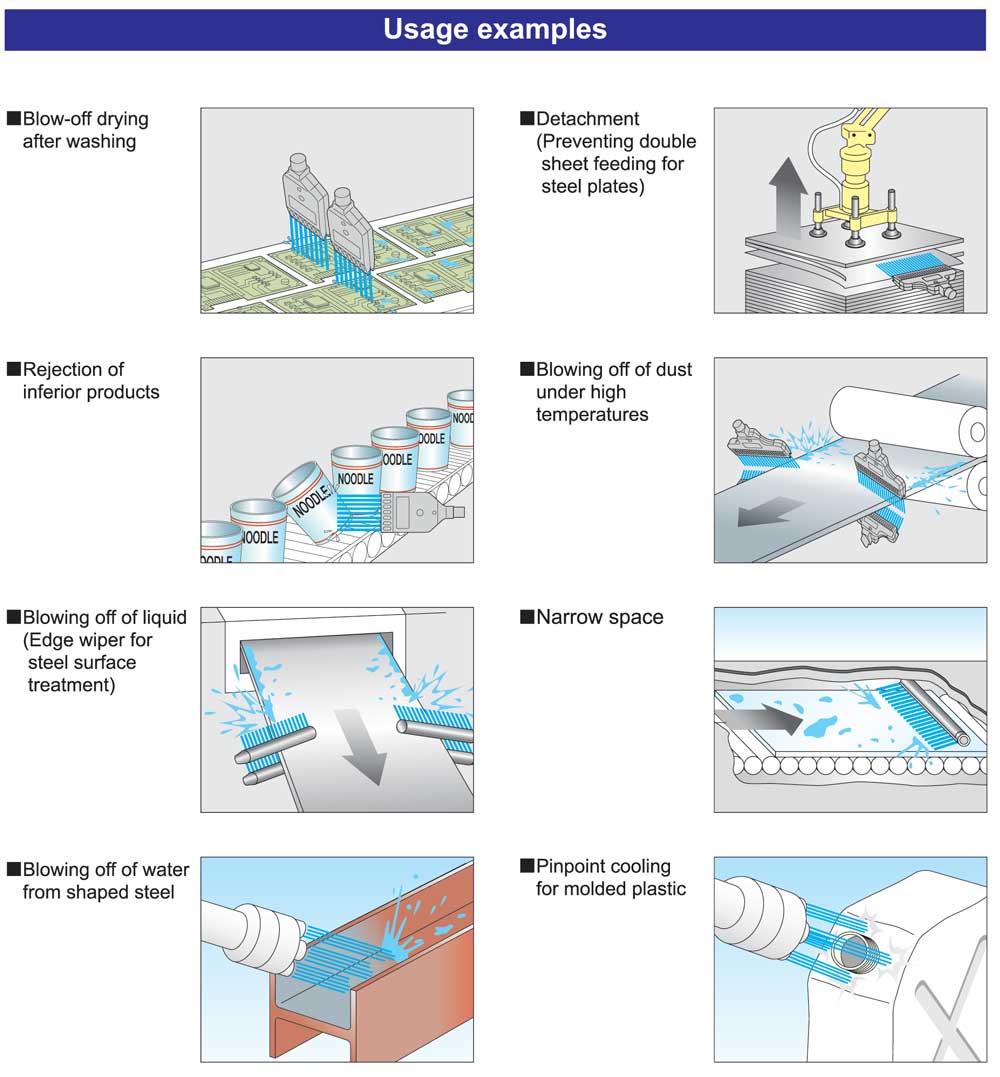

Air nozzles can be used in many different applications like:

There are many areas in which air nozzles can make a difference:

- Increasing productivity and product quality;

- Reducing cost;

- Reducing noise level;

- And more.

Check out our article about how to reduce cost by 70% while increasing the air blowing power

That is why, in order to comply to the EU Directive and OSHA standard when using air nozzles with compressed air, it is important to carefully choose the right air nozzle as it will determine the:

- Performance of the application wanted;

- Exposure to the noise level;

- Usage of compressed air (your cost).

How can we help you?

As a nozzle manufacturer, we have the knowledge and experience to help you choose the right nozzle for your requirements. We have been developing efficient technical air nozzles with a unique design to help you with:

- Reducing the noise level and complying to the regulations;

- Saving compressed air costs;

- Increasing the efficiency of performance (blowing).

1. Reducing the noise level and complying to the regulations

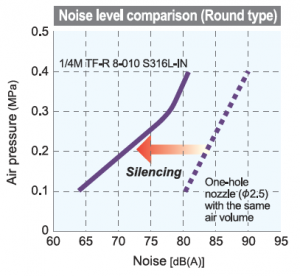

Thanks to our experience, we have been developing innovative technical air nozzles, like the TAIFUJet® series, to have a minimal noise level.

The noise level can be reduced up to 89% compared to an open pipe of the same size.

2. Saving compressed air costs

Our most popular nozzle series, TAIFUJet®, can generate a powerful air current with a high spray impact while consuming almost half the volume of compressed air compared to conventional models.

3. Increasing the efficiency of performance (blowing)

While you are saving on compressed air cost and minimizing the noise level, you will also benefit of the increased efficiency of blowing performance with our technical nozzles!

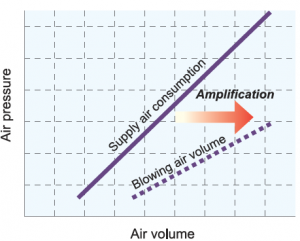

Each technical air nozzle is designed to supply a stronger air current than the volume of air consumed.

For example, the EJA series is designed to take in the surrounding air and blow 10 times more air than the volume supplied. Thus, the air blow generated remains strong while consuming a small volume of compressed air.

If you have a specific requirement / project, don’t hesitate to download our catalog and/or contact us for additional information!