Electronics

Dry Fog Humidification for the assembly process

Process

Issues in the assembly process, SMT Manufacturing

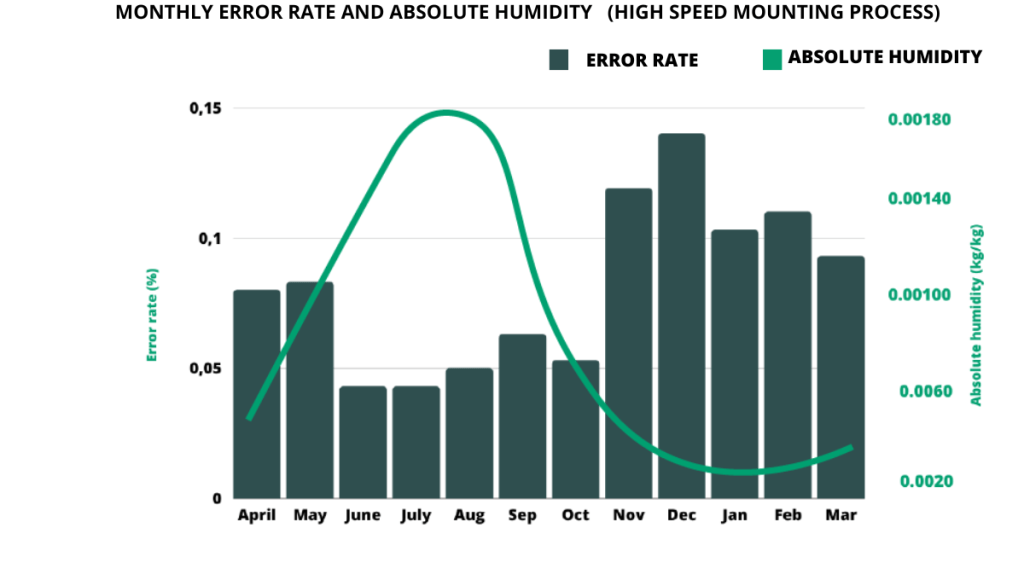

- Humidity level influenced by outside air conditions

- Increased error rate due to a low humidity level, especially during winter

- ESD causing product damages: soldering defect, circuit damage, bad mount

- Dust adhesion

Solution: Dry Fog Humidification system against ESD

By analyzing the existing condition of the facility (e.g. room size, air refreshment ratio, SMT line layout, local climate, etc.), we offer the suitable installation to prevent ESD issues and reduce the defect rate. By adding humidity, it helps to reduce the mounting defect, prevent dust adhesion, and save on existing air conditioning cost.

Download the leaflet

Example of Systems / Products used for this solution

AirAKI® system (Explosion proof version) with the AKIMist® “E” Dry Fog humidifier

- The AKIMist® is a Dry Fog humidification and is recognized as a requirements for soldered electrical and electronic assemblies based on IPC J-STD-001 standard.

Solutions

Benefits

- Productivity increased by reducing the defect rate (failure rate by ESD 1/10)

- Saving energy cost by reducing on air conditioning

- Humidity control

- Product quality increased by reducing mounting defects and improving PCB solder printing quality

- Preventing dust adhesion

AirAKI® system with the Dry Fog humidifier AKIMist®“E” installed in a SMT line

Advantages of this solution

- Double-edged sword: dust suppression and humidification through atomization

- Easy installation by adding-on to the existing HVAC system

- High efficiency with low maintenance

- Easily adaptable to changes in floor layout

Applications

- Spot humidification above SMT lines

- Other applications: humidification, indoor cooling

Related articles

Have a look to our News and Project sections with articles about: