Food and Beverage

Cleaning and washing

Process

Cleaning and washing occur at different stages within the food and beverage industry factories. It can happen in the storing and handling of raw materials, such as: fruits, vegetables, meat, etc. It can ensue in the extraction phase, as the materials are being crushed, roasted, or oil is extracted. Even in the production phase, where cooking, fermentation, dehydration, or distillation take place, it represents a quintessential process application.

The cleaning and washing process is regarded as a fundamental phase within the food production. Why? Because it assists with the maintenance of food safety and a hygienic working environment.

Throughout the food processing stages, soil or residue develop. These residues are attached to the surface of conveyor belts, tanks, or other processing equipment. The cleaning and washing process ensures the rinsing and cleaning of this equipment. Once this is done in an effective and successful way, the equipment can be further sanitized.

Aspects influencing an effective cleaning and washing

As the cleaning and washing process is the predecessor of sterilization, disinfection, or sanitization, it is critical that the residues or soils are completely removed from an equipment’s surface. Thus, this process must be effective. If this process fails, then there is a risk of cross-contamination of other raw materials, food products, or beverage products. It can even become a health hazard, affecting the working personnel, if it is not managed properly.

Frequency is another aspect that can make a difference. Depending on the process line, the cleaning frequency should be clearly identified.

Lastly, the water purity level has an impact on the cleaning efficiency. If the water has alkaline or acidic properties, then other additional buffering agents might be required. On the other hand, as the water contains various other particles and substances, a water treatment and filtering should be considered prior to its use. Utilizing impure water can lead to:

- corrosion

- scaling

- deposition

- filming

- and staining

Solutions

Cleaning and washing spraying solutions

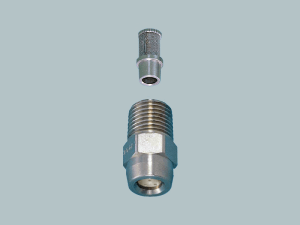

As industrial spraying for the cleaning and washing process, IKEUCHI can provide the following clean-in-place (CIP) solutions:

- Multiple layout uniform cleaning of wide conveyors;

- Bottles and cans’ insides with strong streams precision cleaning;

- Filter cloth dirt removal through high pressure water streams;

- Cleaning the food tank‘s or beverage tank’s inside surface efficiently and automatically through tank cleaners;

- Package cleaning through precisely arranged tapered nozzles;

- Washing and cleaning of complex shaped objects (Food Cans) through a combination of conical and fan-shaped nozzles.

IKEUCHI’s product line of air blowers

Food processing and production industry:

Beverage processing and production industry: