Iron and Steel making

Plate mill & Rolling mill production

Process

Process

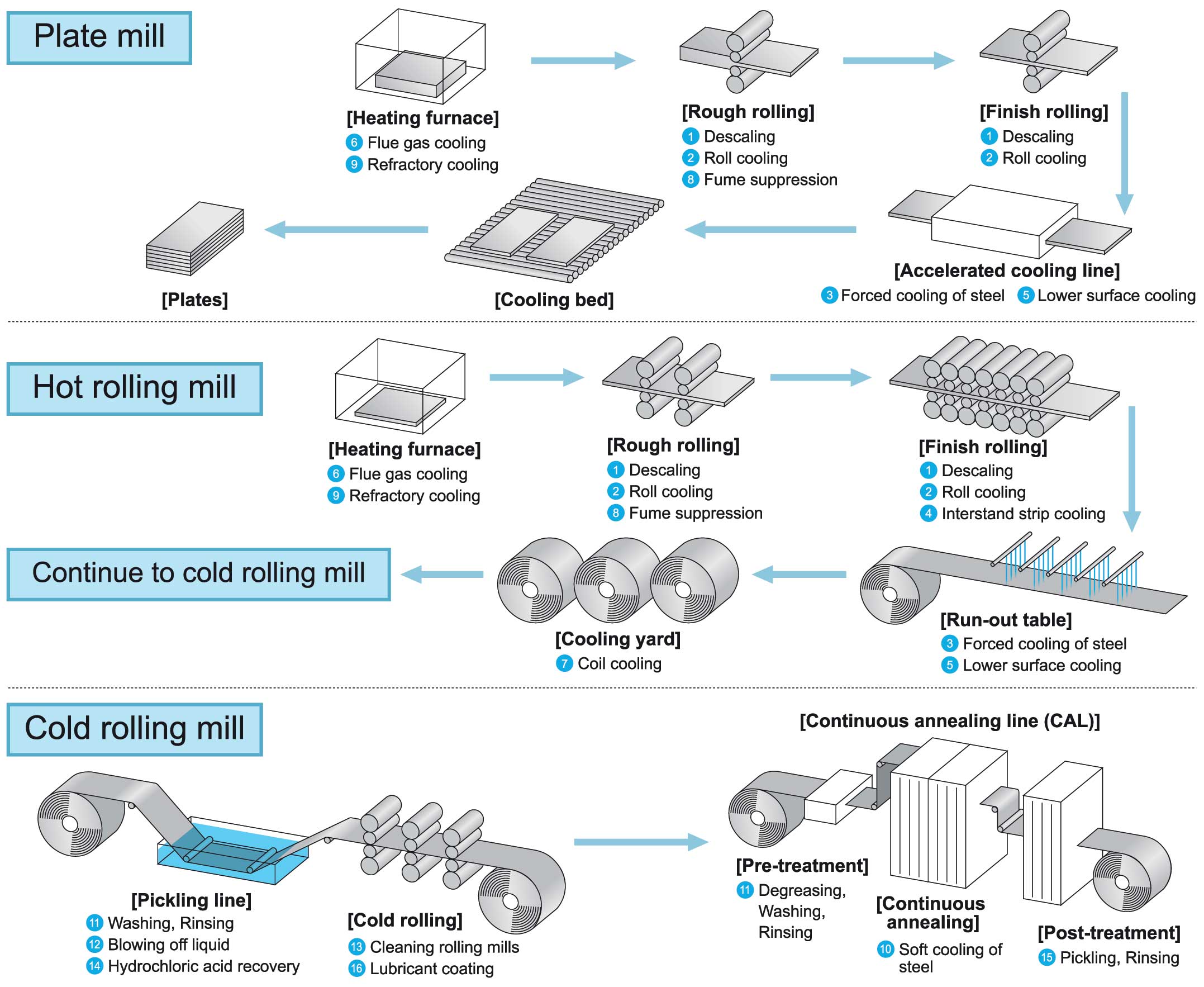

Below are some of the applications we support with our spray nozzles for the production of plate mills and rolling mills.

Applications

We have spray nozzles for:

- Plate mill & Hot rolling mill

- Descaling

- Flue gas cooling

- Refractory cooling

- Roll cooling

- Fume suppression

- Steel cooling

- Cold rolling mill

- Washing, rinsing

- Blowing off liquid

- Cleaning rolling mills

- Lubricant coating

- Degreasing

- Pickling

Solutions

Benefits

Download the Iron and Steel making documents:

- Solutions based brochure: download