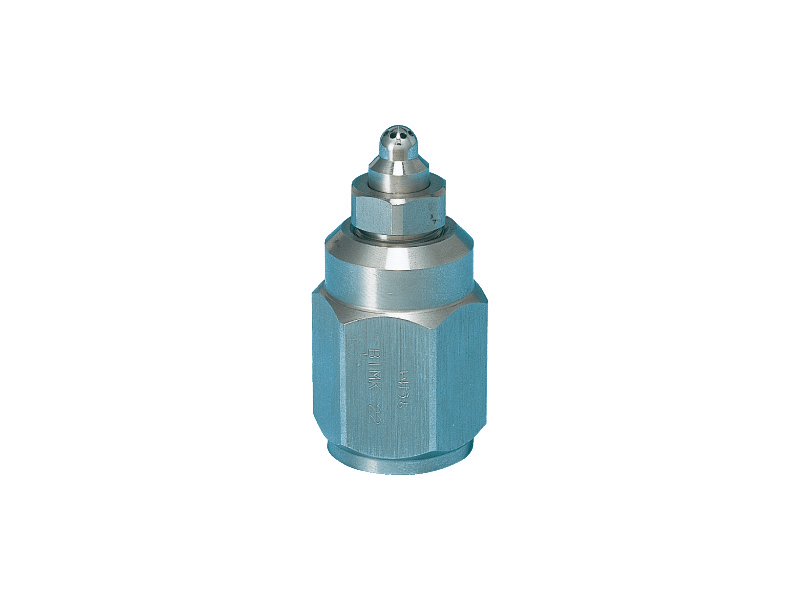

Fine fog hollow cone spray nozzle

BIMK series

Features

The BIMK series nozzles’ features:

- Hollow cone spray pneumatic nozzle producing fine atomization with a mean droplet diameter of 100 μm or less (*3).

- Features large turn-down ratio under liquid pressures of 0.1 – 0.3MPa (ca. 1 bar – 3 bar).

- Spray angle of 60°.

*1) Spray angle measured at compressed air pressure of 0.3 MPa (ca. 3 bar) and liquid pressure of 0.1 MPa (1 bar).

*2) Free passage diameter of nozzle orifice.

*3) Measured by Laser Doppler Method.

Thread standard

-

Pipe conn. size

-

Standard pressure

-

Spray angle

60° (*1)

Spray capacity

2.0 - 107 L/hr

Supply air type

Compressed air

Liquid feeding system

Liquid pressure

Mean droplet diameter

20 - 100 μm

Air consumption

13 - 245 L/min, Normal

Air pressure

0.2 - 0.4 MPa (ca. 2 bar - 4 bar)

Free passage diameter

0.5 - 1.1 mm (*2)

Applications

The BIMK series nozzles have multiple applications:

- Spraying: Mold release agent, lubricant, deodorant (trash pit, refuse collector, inlet conduit), oil, surface treatment agent, rust preventive, insecticide, aqueous urea, etc.

- Cooling: Dies, gas, glass, steel plates, steel pieces, moldings, automobile bodies, plastic products, etc.

- Moisture control: Paper, gas, ceramics, concrete, etc.

- Raw material process: Dust suppression at the conveyor line, Flue gas denitration reducing agent

- Steel making process: Cooling refractories at maintenance of ladle and tundish, Cooling electric furnace and electrode

- Rolling mill process: Cooling coil

- Surface finish process: Minimized spangle treatment at the continuous galvazing line, Cooling coating line

More information?

Do you want to order this product? Or request a quote?