February 18, 2020

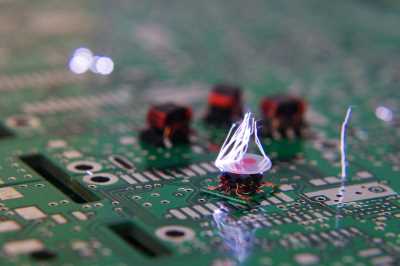

Explosion due to electrostatic discharge

Static electricity can create damages not just with the high voltage flow, but also by creating a spark. That spark can trigger a fire or an explosion depending on the working environment conditions. In various industries and production fields, there are many cases where electrostatic discharge triggers a serious accident such as ignition or explosion.

Examples:

- In the industry dealing with polymer materials with high insulation resistance, the polymer film comes into contact with many rollers, increasing the charge density and causing an electrostatic discharge when the film separates from the metal roller. With a charged film accompanied by a large area, the electric field close to the nearby conductor is also strong, so ignition may occur where there is a flammable atmosphere.

- In the case of combustible gas, spark discharge occurs when it is mixed with air, and the gas may ignite and explode. At this time, the flammable gas is considered to have exceeded the discharge energy threshold.

Causes of sparks

The ignition energy threshold

- Gas

The table shows the minimum ignition energy threshold for spark discharges, in flammable gases mixed with air.

However, since gas ignition is a stochastic phenomenon, the threshold value of minimum ignition energy is not absolute but a measure of danger.

| Name of substance | Chemical formula | Minimum ignition energy |

| Hydrogen | H | 0.019 |

| Acetylene | HC≡CH | 0.019 |

| Ethylene | CH2=CH2 | 0.096 |

| Methanol | CH3OH | 0.14 |

| Benzene | C6H6 | 0.20 |

| Butane | C4H10 | 0.25 |

| Ethane | CH3CH3 | 0.25 |

| Propane | CH3CH2CH3 | 0.25 |

| Methane | CH4 | 0.28 |

| Acetone | CH3COCH3 | 1.15 |

- Powder particles

The ignition energy in the case of powder is larger than the gas one. However, it is dangerous if the conductor is charged or the density of charged dust is high. Also, the finer the powder particles, the lower this energy value and the greater the risk of explosion due to electrostatic discharge.

- Viscous substance

In addition, when dealing with oil, the danger increases. Irregular actions such as cleaning the inside of the tank of a crude oil tanker may cause an electrostatic discharge, which may cause an explosion. In the medical field, treatment using an oxygen tank or oxygen tent can lead to ignition due to electrostatic discharge caused by charging of clothes.

Electromagnetic interference

Electromagnetic waves are generated by electrostatic discharge caused by steep pulse discharges.

Obstacles caused by electromagnetic waves can:

- be a source of noise in measurement and communication equipment at the production site,

- affect the system,

- cause malfunctions and damage the system.

For example, when suddenly rising from a steel desk during the dry season in winter, a strong electrostatic discharge occurs when a human body touches the desk. At that time, if you are using a personal computer on your desk, the machine may stop working.

In the case of devices such as personal computers, there is almost no case of damage to the internal devices. However, for example, when a production plant is controlled by computer devices, the effects of device malfunction due to electromagnetic interference are large. This will result in losses. In addition, electromagnetic waves generated by electrostatic discharge contain a wide range of frequency components, so the range of influence is widened.

Related articles

If you want to learn more about how static electricity occurs and what to do to prevent ESD, here are our compilation of articles we covered:

- Static electricity:

- Our solutions for ESD prevention:

- Case Study of an installation: Manufacturing of car audio system

How can IKEUCHI help?

As mentioned, it exists many cases where electrostatic discharge triggers a serious accident. Spark can trigger a fire or an explosion.

IKEUCHI can help to prevent explosion by reducing ESD with a humidifier. Adding moisture in the air will increase the conductivity. Therefore, they will be no more discharge and no risk of sparks.

That is why, as “the Fog Engineers” we’ve studied the optimal solution to prevent electrostatic discharge (ESD), by adding humidity in working environment. Our none-wetting Dry Fog humidifier offers the adequate solution for sensitive working stations.

Contact one of our engineers to assess the optimal solution to prevent ESD in your production site.