May 30, 2025

Spray coating for the food industry

Spray coating nozzles are a critical component in many food and confectionary productions and range from fine mist atomization to thicker coating layering. These nozzles are designed for precision and to deliver uniform and consistent results. In addition, coating nozzles lead to minimized waste and will help to live up to the stringent hygiene and safety standards in the food industry.

Why are spray nozzles better for precision coating?

Spray nozzles are ideal for food coating applications due to their controlled spray patterns and adjustable flow rates. The fine atomization delivers uniform layers, while reduced overspray lowers material costs and maintains cleanliness.

1. Even Distribution

-

Precision atomization breaks the liquid into fine, uniform droplets.

-

This creates a smooth, consistent layer over the product surface—important for both aesthetic and functional purposes.

2. Reduced Waste and Overspray

-

Targeted spraying minimizes excess material use, leading to lower costs and less cleanup.

-

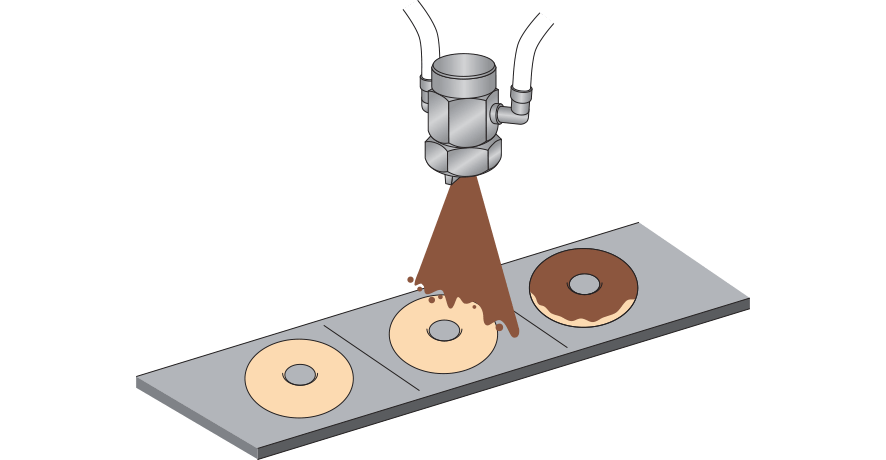

This is especially beneficial for expensive coatings like chocolate or specialty oils.

3. Cleanliness and Hygiene

-

Precision means less splatter and waste around the equipment, contributing to a cleaner processing environment.

-

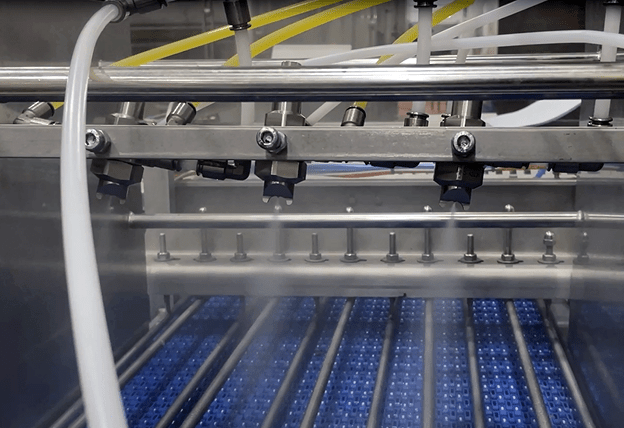

Many food-grade nozzles are also easy to clean or compatible with CIP (Clean-In-Place) systems.

How to Choose the Right Spray Nozzle for Different Coating Applications

Choosing the right spray nozzle for food coating depends on several key factors related to the coating material, application requirements, and production environment. The most important factor is the viscosity of the coating you wish to apply. Where glazings of lower viscosity can best be applied with an air atomizing spray nozzle, products of higher viscosity can sometimes better be sprayed with a hydraulic spraying solution:

Low viscosity: Water-based solutions: An air atomizing spray nozzle with a very small droplet size

Medium viscosity: Oil, glaze, egg etc. : An air atomizing spray nozzle with a small droplet size

High viscosity: Chocolate, honey etc. : An air atomizing or hydraulic spray nozzle solution

Customer examples of different coating applications

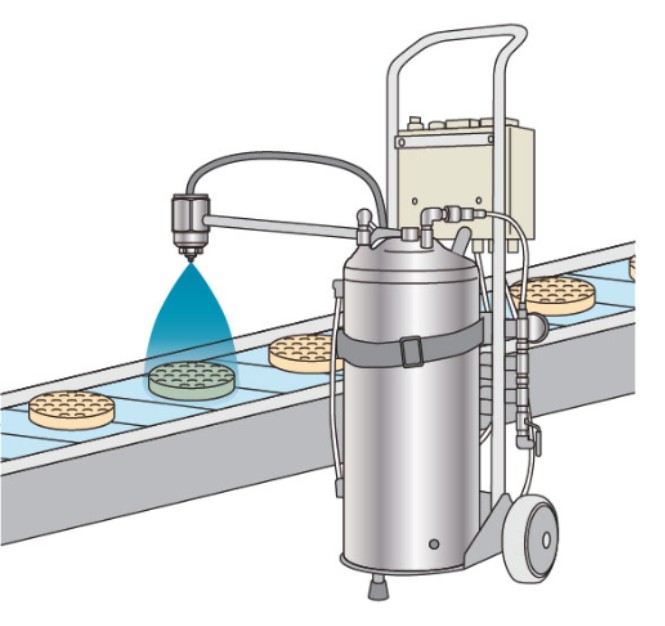

Alcohol disinfectant spray coating

For this project, the customer was looking for a disinfection spray coating for their fish cake, before entering the steamer. Before the project started, the factory used 5 tons of disinfectant liquid per month, but after the implementation, this was reduced to just 1.5 tons, an astonishing 70% reduction in consumption.

In this case, the CBIM-V was implemented as it is able to provide the lowest spray flow rate among all of our pneumatic spray nozzles. In addition, it has a clog-resistant design with a low parts count and is available with a spray control adaptor which can regulates spray ON/OFF with a built-in piston.

Oil spray coating

For this project, the customer was looking for a an oil spraying solution to apply a thin layer of olive oil on sardines in a can. The customer wanted to control the quantity of sprayed oil with a suitable droplet size, providing the sardines with the right amount of oil and not waste it, to assist in keeping and preserving the sardines’ skin intact.

In this case, the SETOV-C +SP series nozzle was recommended for implementation, as it is optimal for coating with products of medium viscosity, like oil. Read the whole case study here