Food and Beverage

Cooling and thawing

Process

To ensure the maintenance of raw and end-products quality, the processes of cooling and thawing (defrosting) are imperative F&B standards. Cooling is implemented to decrease a product’s temperature to assist its transition from one stage to another. Moreover, the temperature can also be maintained for other food and beverage processes (e.g.: fermentation, beer processing). Through effective cooling:

- processing times are shorter and also contributes to energy savings;

- the product’s characteristics are preserved (taste, color, smell);

- the acids and tartrates are stabilized in beverages before bottling, maintaining the product’s quality and integrity;

- the food’s microorganisms are reduced, increasing the lifespan and freshness of the products;

- the product’s state transitions or aggregates, leading to crystallization.

Currently there are multiple types of cooling, which are applicable to the food and beverage industry, such as:

- Air blowing

- Adiabatic cooling

- Precision cooling

- Vapor compression (water/ fluid / air chillers)

- Vapor absorption (through heat)

- Water cooling

Thawing or defrosting in the food and beverage industry

On the other hand, the process of thawing refers to the defrosting of a product (frozen food) to a temperature of slightly above 0° C. This state is where there’s no residual ice. Moreover, at this point the temperature plays a critical role not only for food safety reasons, but also for quality reasons. Freezing doesn’t kill bacteria; it only stops its growth. However, through thawing, bacteria can reemerge and spread. This leads to bacteria causing spoilage, food poisoning, or contamination.

Thus, the implementation of food safety protocols and standards should ensure that the bacteria is minimized. To do so, thawing or defrosting should occur at a temperature of under 5° C (within refrigerators). Furthermore, another possibility is to submerge the frozen products under running water, at a temperature of 21° C or lower. The running water flow should be high enough to wash away the food particles directly into the drain. This eliminates the risk of contamination.

Solutions

Cooling and thawing spraying solutions

Depending on the type of application, IKEUCHI provides you with the spraying or fogging nozzles, and fogging systems as a food and beverage solution:

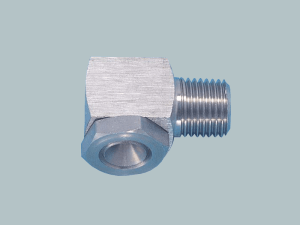

- Conical and fan-shaped spray nozzles effectively cooling to thermally sterilize food;

- Freezer defrosting or thawing through warm water even spraying.

IKEUCHI’s product line of cooling and thawing nozzles