Food and Beverage

Sterilization and disinfection

Process

Depending on the necessity and requirements, sanitization, or sterilization and disinfection, can be implemented. These processes succeed cleaning and washing in the food and beverage production. Thus, once the equipment is cleaned, and the soils and residues are rinsed off and removed from the surface, microorganisms continue to exist and can further contaminate the working environment. Moreover, disinfection relates to destroying the bacteria and viruses from all surfaces. Furthermore, sterilization relates to killing all existing microorganisms.

On the other hand, the purpose of sanitization is to remove the harmful bacteria from surfaces. In the case of disinfection and sanitization, specific procedures must be followed to ensure the minimizing of harmful microorganisms up to a safe and suitable level for the food and beverage production.

Besides reducing the number of microorganisms, they also assist in maintaining a hygienic state, preventing foodborne diseases, and cross contamination from occurring and spreading.

Manual vs automatic labor

When it comes to sanitization, disinfection, and sterilization, food and beverage companies must consider the fact that manual laboring:

- can affect not only the consuming products, but also the employees and consumers;

- is tedious and ineffective, in some cases;

- applying chemicals can be harmful, if they are not carefully handled;

- the application of chemicals requires a large quantity of waste water;

- not ensuring that the raw products, end products or equipment are hygienic or safe, can create a health hazard.

However, through the implementation of automated systems the above concerns are put to rest. Besides this, through automation it is possible to regulate the spraying quantity and frequency of spraying of sanitizers, disinfectants, or sterilizers.

Regarding sanitization, the implementation of certain systems can deliver a hot-water sanitization. This process relates to immersion or spraying.

Solutions

Sanitization, sterilization, and disinfection spraying solutions

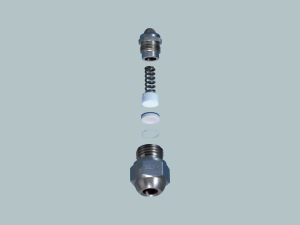

Depending on the type of application, IKEUCHI provides you with fogging nozzles, and fogging systems as a food and beverage solution:

- Efficacious sterilization and drying of conveyors through fine fog spraying;

- Complete area disinfection, including narrow corners through Fog humidification;

- Effectively sterilizing and disinfecting containers through hot water low pressure spraying for pasteurization (dairy products).