Paper and Pulp

Drying process

Process

The drying of paper in the paper mills

One of the longest sections of a paper machine relates to the drying units.

- The heated drying rolls dry the paper, which makes it solid and self-supporting.

- The paper goes through a machine calendar where two extremely polished steel cylinders are determining if the paper thickness is consistent and even.

- The paper continues to pass through a series of sizing and coating presses. Then a film pressed process is applied through color coating and starching of the paper.

- The coating color is sprayed on an elastic roll which in contact with the paper transfers the coating film on the paper web.

- After this process, the paper is again dried though infra-red heat panels or drying cylinders. The paper is wound on steel cores, which press against a pope reel to ensure that the paper is wound at the suitable tension. This process is also called the drying process.

Solutions

The nozzles’ role as solutions in the drying process

Once the paper is transferred from the trimming section, it arrives in the pre-dryer. In this part, the paper is sprayed with lubricant to ensure that the friction between the paper and the rolls is reduced. The BIM series nozzles are recommended for this particular task thanks to their fine fog flat or hollow cone spray pattern:

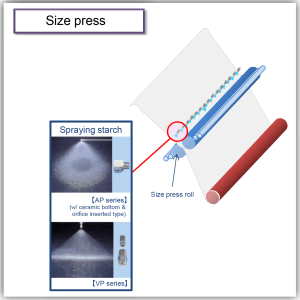

The next step is the size press. After the pre-drying section, the paper is transferred in the size press where nozzles are spraying starch onto the wet web of paper. This process is required to enhance the binding of the paper fibers, making it stronger and durable. The nozzles that can assist with the spraying of starch are the following:

The paper is then transported to the dryer canvas. Within this section a series of nozzles is requested to be installed to ensure that the dryer canvas is kept clean. The BIM header nozzles are suitable for this type of operation, as they provide a uniform distribution. Moreover, the volume of spray can be controlled, which assist in reducing the amount of utilized spray. The paper is then transported to the drying section.