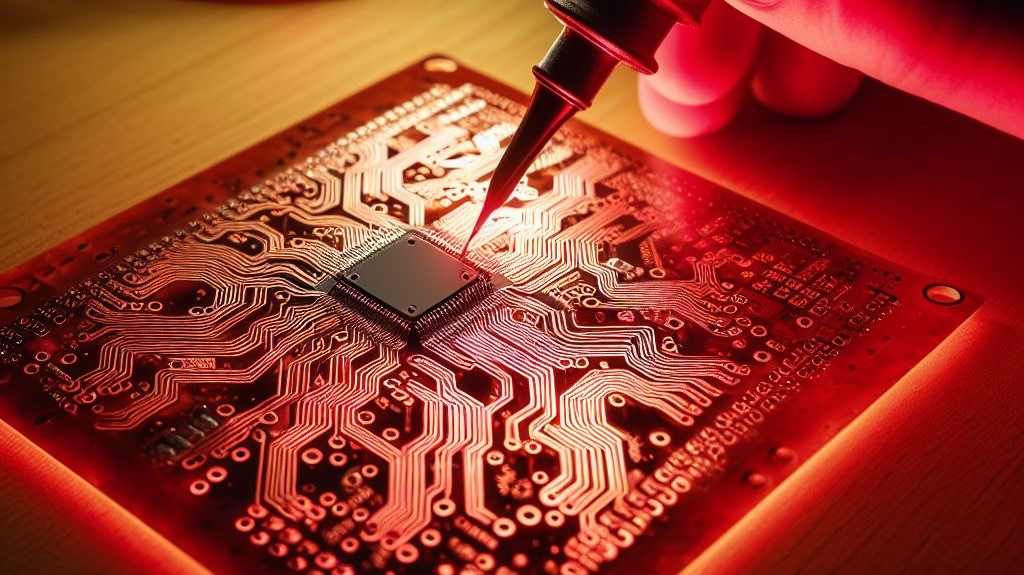

Electronics

Spray Nozzles for the Wet process

Process

Issues with cheap production spray nozzles

What happen during the wet process with lower quality nozzles?

- Nozzles with disparate spray capacity

- Uneven spray impact for precision cleaning

- Low washing ability

- Difficulties to design an effective layout

Solution: Surface treatment and cleaning application with our high quality nozzles

During the wet process, each step has a specific need for which we can provide the most adapted nozzles. From improving the cleaning capacity, the etching capacity, to saving the chemical liquid amount and rinsing water amount, we analyze existing cleanings tools and current process.

Example of Systems / Products used for this solution

Developing process

Spray nozzles for precision developing:

Etching process

Spray nozzles for high-efficient fine etching and easy maintenance:

- INJJX-Y series

- JJXP series

- SSXP series

- JJRP series

- INVVEA series

Stripping process

Spray nozzles for highly chemical-resistance:

- INJJX series

- AJP-PPS series [PPS-injection molded AJP are available for excellent chemical and heat resistance]

- INVV series

- VVP series

Cleaning / Rinsing process

Spray nozzles for precision cleaning:

Solutions

Benefits

- Productivity increased

- Less maintenance

- Saving chemical liquid amount

- Saving water amount

Advantages of this solution

- Guarantee of performance on our nozzles

- Productivity increased due to high quality spray (spray capacity, spray angle, and spray impact) nozzles

- Other application: cleaning

Related articles

We’ve covered the importance of high quality nozzles VS. cheap production nozzles and copy products in several articles: